PCBAの加工プロセスには、PCB製造、部品調達とチェック、SMDアセンブリ、DIPプロセス、プログラミング、テスト、エージングと一連のプロセスが含まれ、サプライチェーンと製造チェーンが長すぎると、多くのPCBAボードに障害が発生します。しかし、PCBAプロセスの品質管理は、故障のほとんどを避けることができます...

カテゴリーアーカイブ: Uncategorized

Conformal coating also seen as PCB coating is a PCB assembly process which aims to protect the final PCBA products from nature damage and become more durable. Typically , the conformal coating material is thin polymeric film. The PCB assembly products which are processed by conformal coating can resistant some environmental factors, such as moisture,…

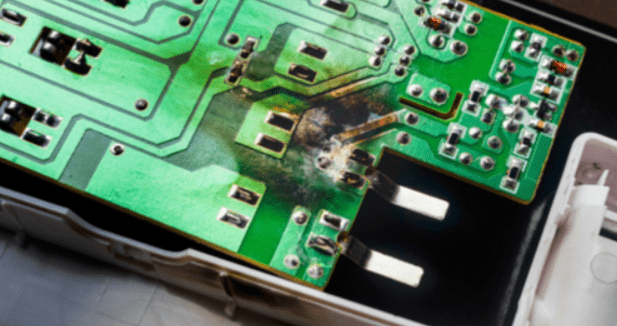

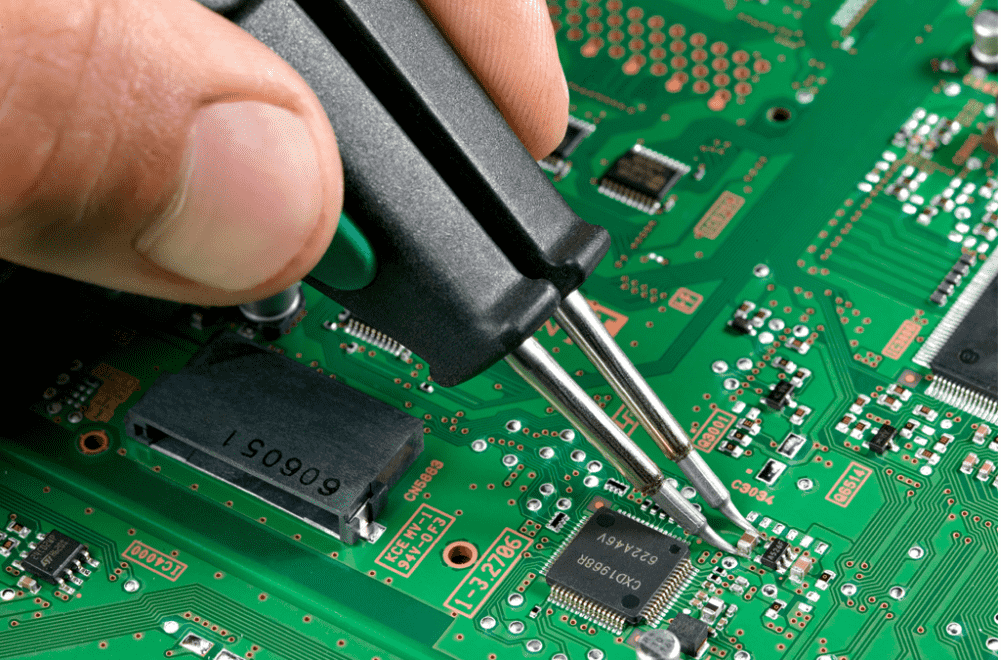

There are some important steps you can take to check for short circuits in your PCB: Step 1: How to find a short circuit board in PCB?Step 2: How to Check Short Circuit board in PCB?Step 3: How to find faulty components on a PCB?Step 4: How to test the PCB destructively? If you have…

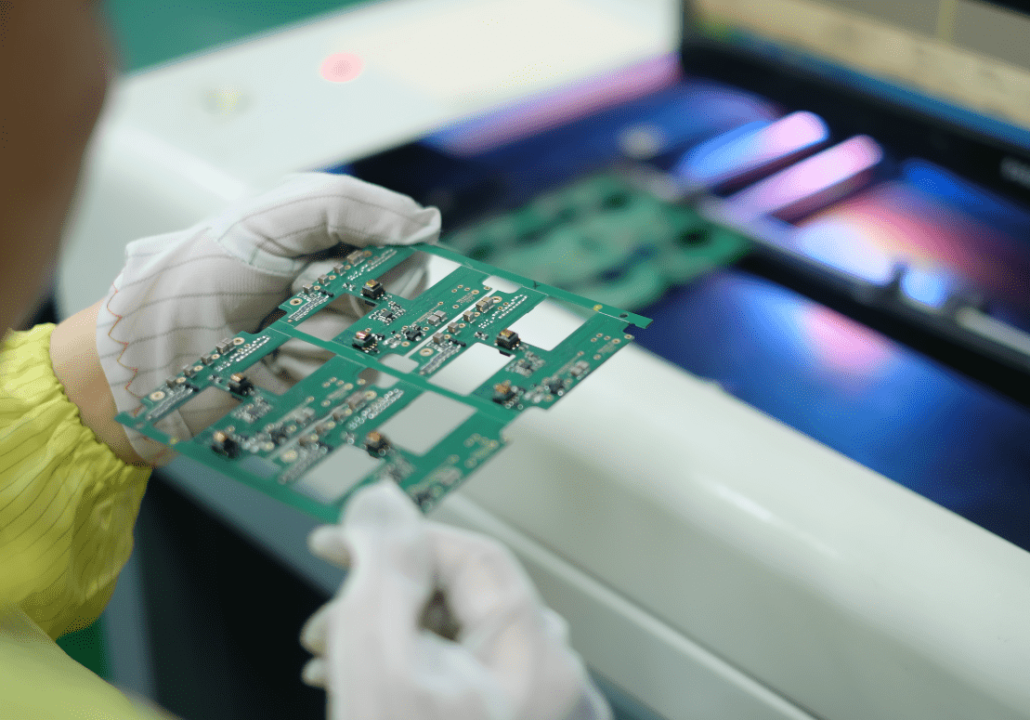

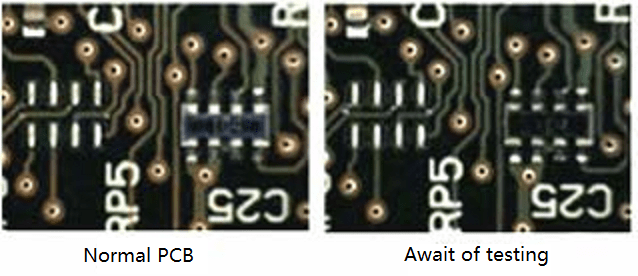

With the rapid development of mobile phone, electronics and communication industries, the PCB circuit board industry continues to grow and grow rapidly, at the same time, people have higher requirements on layer number, weight, precision, material, color and reliability of PCB. So how do you tell if a PCB is good or bad? However, due…

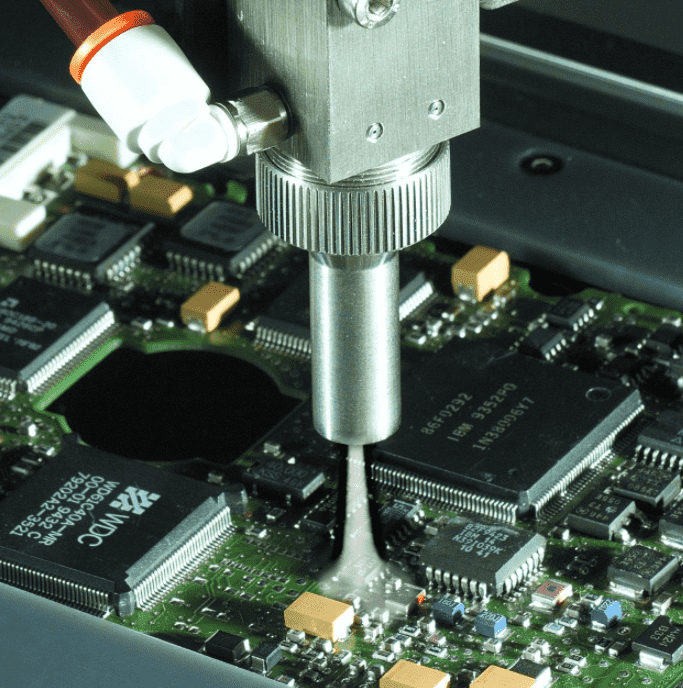

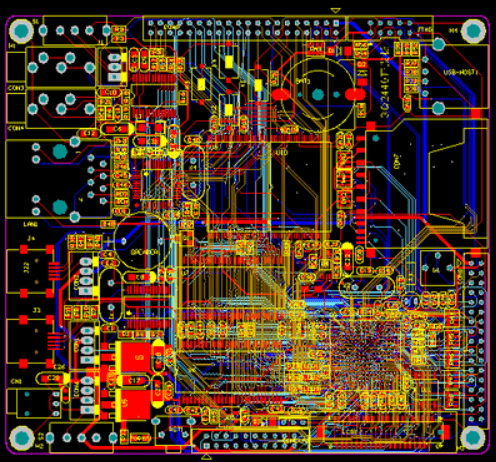

Working principle of AOI detector testing Application of AOI in SMT processing in a variety of forms, but its basic principle is the same (as shown in Picture 1), the analyte with optical instruments for graphics, usually by sensors (cameras) to obtain the test figure like lighting and digitization, and in some way to compare,…

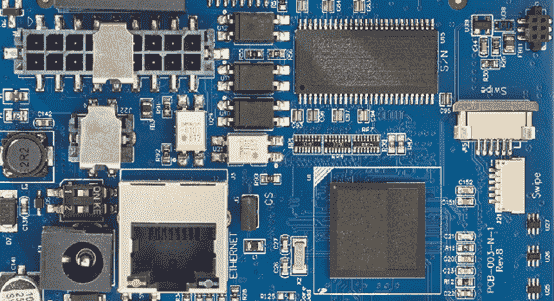

As today’s electronic designs become more advanced and complex, more and more engineers rely on surface mount technology. The technology is now the PCB assembly technology of choice for many smt assembly manufacturers. Whether it’s medical, military, aerospace, or other fields – it’s all likely to be manufactured through surface mount technology (SMT). So, what…

It’s a tough job for OEMs to settle on a long-term PCB fabricator or assembler (we’ll call them PCB Houses in the following paragraphs) since the globe is flooded with too many PCB services providers. This article brings some guidelines on how to picking up the perfect fit PCB Houses from your long waiting list….

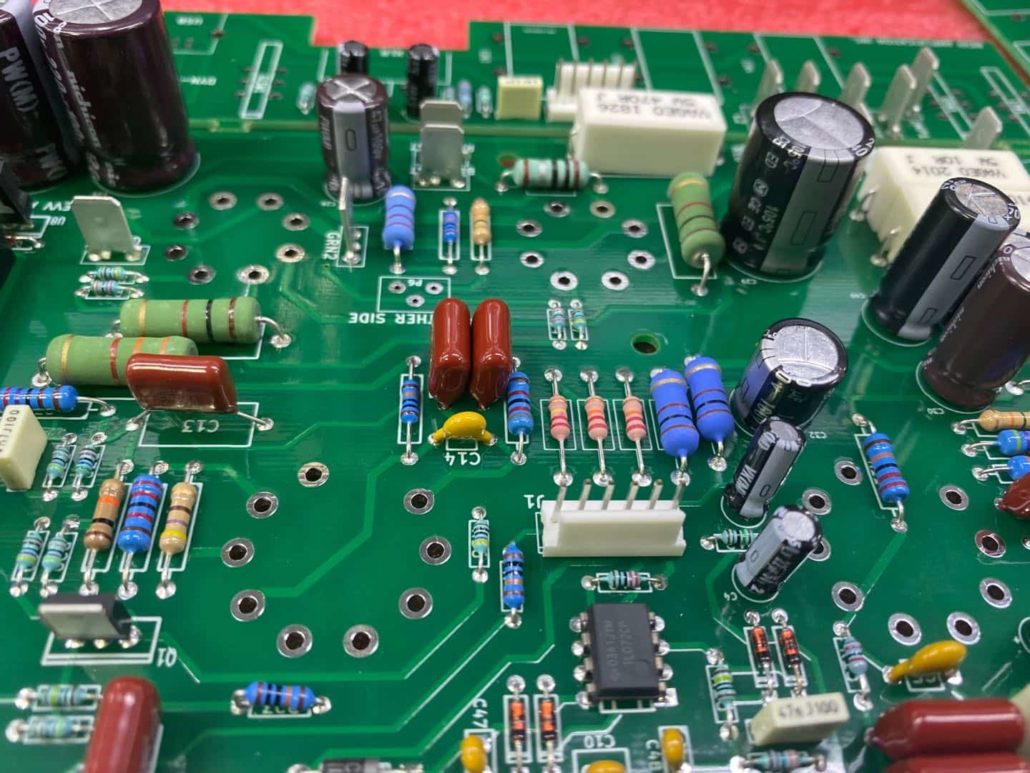

What are the reliability tests in the PCB assembly manufacturing? PCBA manufacturing is by no means a combination of adding material procurement on the basis of SMT processing. Any problem of any material will affect the overall result of PCBA board, which requires us to have sufficient material detection ability, supplier management ability, technical…

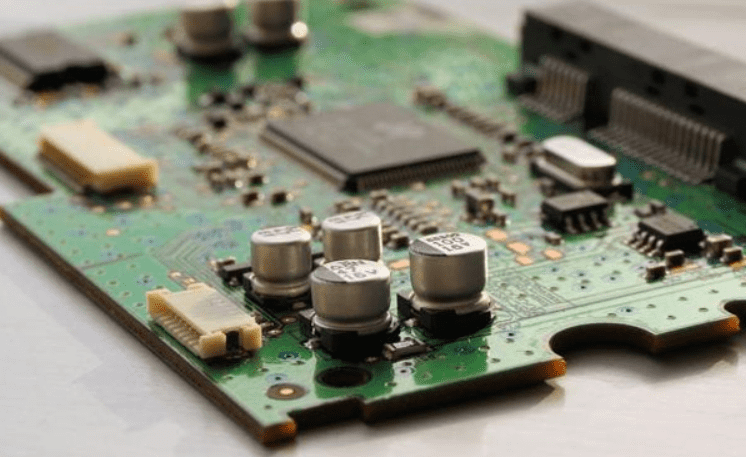

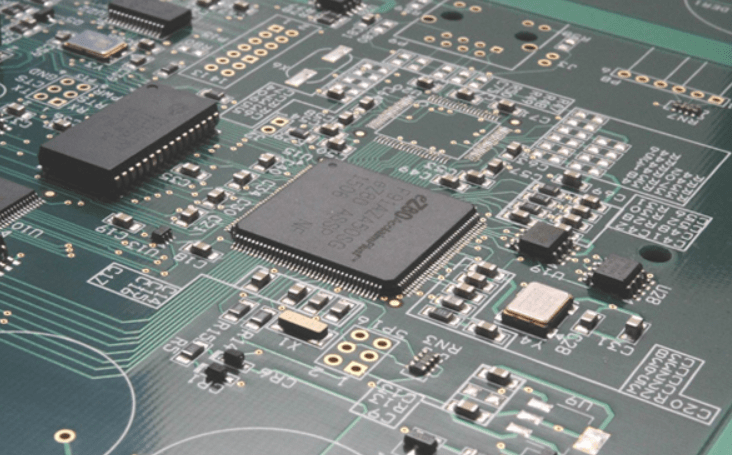

What You Need To Know About PCB Manufacturing And PCB Assembly? What Are PCB ? PCB is the acronym of Printed Circuit Board, a mechanical base that contains tracks and footprints reflecting the schematic of the design. Printed circuit boards (PCBs) are the foundational building block of most electronic devices. From a simple single board used…

16 requirements of SMT process for component layout design The layout of components should be designed according to SMT electronic processing equipment and process characteristics and requirements. Different processes, such as reflow soldering and wave soldering, have different layouts for components. When double-side reflow soldering, there are different requirements for the layout of side A…