Have you ever seen a circuit board from the 19th century? They were big, heavy, and surprisingly simple. If you open the old tech, you will find thick wires crisscrossing a chunky frame, soldered by hand. Previously, there were no advanced PCBs, so people didn’t pay much attention to PCBA.

However, today, things are getting smaller and more complex. Instead of chunky frames, people like more compact and light devices. That’s where printed circuit boards (PCBs) are used. Modern circuit boards are light, compact, and packed with thousands of components. Traditional knowledge alone cannot assemble these components; specialized PCBA technology is required.

The assembly process on PCB is typically called the PCBA process. These circuit boards are more functional and durable. If you want to learn more about PCBA, this article is for you. It starts with highlighting the fundamentals of PCB assembly. Next, you will have a quick view of how PCBA works. What are the different types of PCBA?

What is PCB Assembly?

PCB Assembly is also widely known as PCBA. Therefore, PCBA means assembling circuit boards. Let’s break it down!

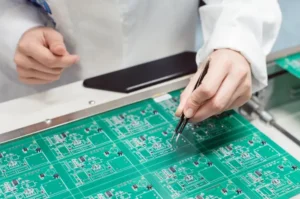

Suppose you have a blank piece of PCB with routes, layers, and holes. Now, you will add all the components to make the PCB functional. The whole process of connecting components is called PCBA or PCB assembly.

Most people make mistakes when understanding PCB fabrication and PCB assembly. PCB fabrication makes the board, while assembly places components on it. In this case, components means resistors, capacitors, microchips, and the rest. They are what you see on a PCB board. Therefore, the two terms are entirely different, and their procedures are also different.

You can not randomly put components on the PCB. There are always rules and standards that you must follow. These rules and standards typically ensure that you make high-quality circuit boards.

PCB assembly ensures proper device functionality. If the assembly is done poorly, the device may malfunction or fail altogether.

You might finish assembly without rules, but results may vary considerably. Therefore, proper PCBA processes improve your device’s reliability.

Proper PCB assembling reduces defects and failures. Because of this, you can ensure fewer breakdowns and a longer device lifespan.

Proper PCBA is also very important for your device’s safety. Poorly assembled PCBs can overheat, short-circuit, or are more prone to damage.

What are the PCBA Components

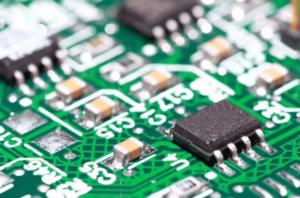

PCBA components are those you see on the PCB. They are mounted onto the PCB to create a functional circuit. The tiny things on the PCB communicate with each other to do something that helps people with their work.

When they communicate, each component has a specific role in the operation. Therefore, it’s very important to understand them. The following four types of components are typically used in PCBA.

Active PCB Assembling Components

Active PCBA components need an external power source to work. You may think of transistors, which can be used to amplify signals. On the other hand, diodes allow current flow in one direction only.

Active PCBA components typically control the flow of electricity in a circuit. They may either amplify signals, generate energy, or switch currents. These components are widely used in dynamic and complex circuits.

Passive PCB Assembling Components

On the other hand, passive PCBA parts don’t need a power source to work. Most of the time, they store, block, or control electrical energy. There are resistors, capacitors, and inductors that come to mind.

For instance, resistors lower voltage and stop the flow current. Capacitors are more like electric storage systems. They store the electricity for a short period and send it out again. Inductors do the same thing but in magnetic fields. So, you can realize that passive PCBA parts protect your circuit from failing.

Connectors

As the name suggests, connectors connect the PCB with external devices. They are crucial for integrating PCBs into larger systems. Examples include USB and power connectors, ring-spade terminals, audio, video, etc.

Special PCBA Components

Some PCBA parts are neither active nor passive. They usually have special features that improve the PCB’s performance. Sensors and microcontrollers are two examples.

Microcontrollers can be small or big, depending on the job. They manage certain jobs in computer systems. Sensors can tell when things in their surroundings change. They check for light, temperature, movements, and more.

Usually, these high-tech parts are found in gadgets that work very well. The world we live in now depends on technology, and microcontrollers are at the heart of it.

Printed Circuit Board Assembly Process

PCB assembly process can be of various types. However, through-hole and SMT assembly processes are the most common. You will learn more about their types in the following section.

Whatever the process type, each PCB board generally undergoes soldering and component placement.

The main connection job generally starts by making the solder paste. When it is hot enough, an operator puts it on the board. Of course, the method of applying the solder paste may vary depending on the PCB assembly. However, you can later use a hand or machine to place the components. Note that in the PCBA, the components are placed first through the hole.

After that, these boards are reflow soldered to keep the parts in place. Finally, you can test the PCB to ensure it works as expected.

Read the article “PCB Assembly Process” to learn more about the PCBA process. This guide explains everything from designing to packaging and will give you a clear understanding of PCBA workflows.

Types of Circuit Board Assembly Process

As mentioned earlier, there are several types of PCBA Assembly Processes. Each process has unique advantages and is meant for a specific type of PCB. Below are the common types:

Single- and double-sided PCB Assembly

A single-sided assembly has components on only one side of the PCB. It is simple, cheap, and easier to assemble. On the other hand, a double-sided assembly uses both sides of the PCB for components. These PCBs are ideal for more complex circuits, especially those with limited space. However, double-sided PCBs are much more expensive than single-sided PCBs.

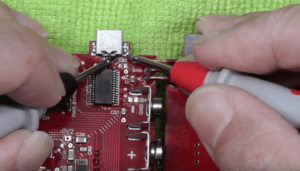

Through the Hole PCB Assembly Process

As the name implies, this PCBA method assembles components using a through hole. Because of this, this method is also renowned as TH PCB assembling.

This process inserts components that lead through holes in the PCB. The leads are then soldered on the opposite side. Among the benefits, TH printed circuit board assembly is much stronger than other methods. They are perfect for equipment that involves vibrations. However, TH PCBA is a slow and costly process. It produces waste and is very limited to making small devices.

BGA Assembly

BGA stands for Ball Grid Array. Connecting high-density components using the traditional soldering method is quite challenging. Thus, engineers developed an excellent solution called BGA assembly.

This method uses tiny little solder balls to connect chips on the PCB. The placement is accurate, saving much space on the PCB. Also, you don’t have to worry about making holes.

SMT PCBA Manufacturing

SMT, or Surface-Mount Technology PCBA, is ideal for mounting components directly on the surface. It doesn’t need holes. BGA assembly is a part of SMT PCBA.

SMT PCBA is faster and more accurate than TH PCBA. This method is ideal for compact and lightweight electronic devices.

Wave Soldering Process

In this process, the PCB is covered with a wave of hot solder, linking the board to the parts. Because of this, you don’t need to connect components one by one, which saves much time. Therefore, wave soldering is widely used in large-scale production.

Mixed PCB Assembly

This combines through-hole and SMT processes on a single board. It is used when both technologies are needed. Mixed assembly is common in advanced electronics.

How to Choose the Right PCBA Manufacturer

If you want a good quality PCB, you must find the right place to make it. In this case, you must find the right PCBA manufacturer for your products. The proper manufacturer can ensure quality, reliability, and, of course, cost-effectiveness. You can follow the tips below to

Tip #1 Choose a PCBA Manufacturer with a proven track record and deep industry knowledge.

Tip #2 Always ensure the company strictly follows ISO 9001 and IPC standards. These standards are especially necessary for parts replacements.

Tip #3 Once you have checked the above two, now check whether the company’s capabilities. Can they handle your specific needs? Can they deal with high-density designs, BGA, or fine-pitch components?

Tip #4 You can also check whether they offer prototyping. Besides, you must know whether they can scale the production to meet your project needs.

Tip #5 You can also compare their quotation with others. Is their price more expensive than others? How about the cost of quality and materials? Does the quotation match the quality and materials they provide?

Tip #6 Finally, take a moment to see how positive the customer reviews are! They can often clarify any confusion, so do not overlook them!

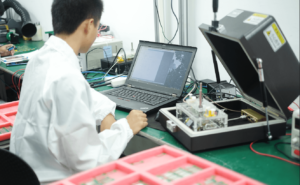

PCBA Services at UEPTCB

UETPCB is one of the biggest companies in the world. It offers all types of PCB manufacturing and assembly services. Whether you need component sourcing or contract manufacturing, this place is one for all. The company has been in business for almost twenty years and uses foreign standards such as ISO 9001 and IPC.

The company can handle all types of PCB production and can offer a good quotation for a high-density or TH PCB. Also, don’t worry about prototyping. UETPCB offers one of the fastest prototyping solutions for its customers.

If you have any questions, contact our customer support team. Our professional team of experts is always happy to help.