300+

Professional Employees

5000+

Satisfied Customers

10Years+

Focus On PCBA

99%

On-Time Delivery

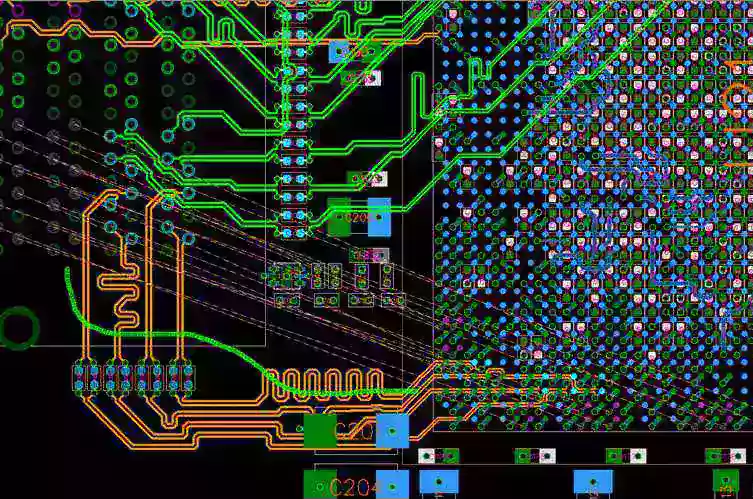

UETPCB is a professional pcb supplier & pcba manufacturer in Shenzhen. We focus on providing high-quality PCB assembly services. As a reliable PCB supplier, we provide one-stop service from PCB manufacturing to assembly. Our professional team has the experience and skills to meet the needs of various industries. Our goal is to be your preferred partner in China PCBA manufactory. If you need quality PCB assembly services, please contact us.

Quick-turn prototype PCB with low cost.read more

√ Layers: 1-8

√ Quantity: 5-1000 pcs.

√ Quality Grade: Standard IPC 2

√ Lead time: 2-9 days

√ Material: FR4

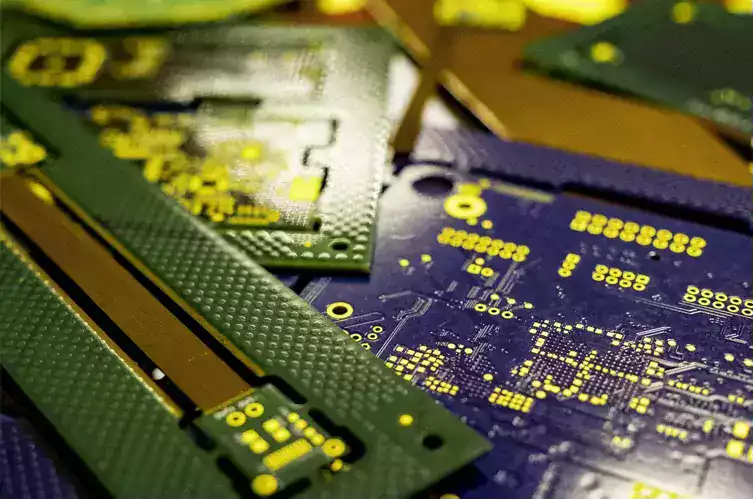

Full feature FR4 PCB fabrication.

read more

√ Layers: 1-32

√ Quantity: 1-1million pcs.

√ Quality Grade: Standard IPC2

√ Lead time: 2 days-5 weeks

√ Material: FR4

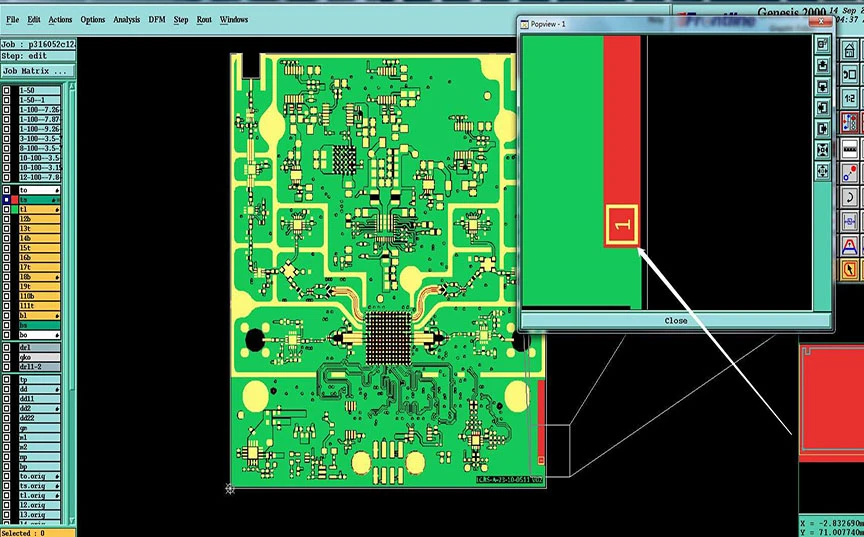

Complex PCBs for optimal perfor-mance in your application. read more

√ Layers: 1-32

√ Quantity: 1-1million pcs.

√ Quality Grade: Standard IPC1

√ Lead time: 12-15 days

√ Type: Flex, Rogers, Alu, etc.

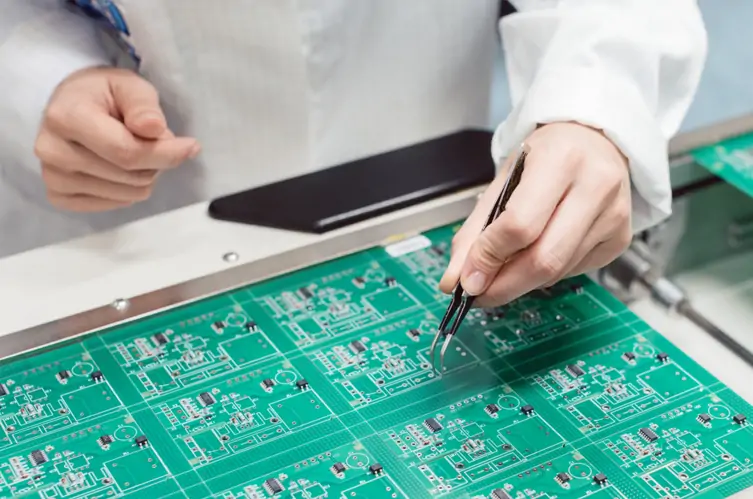

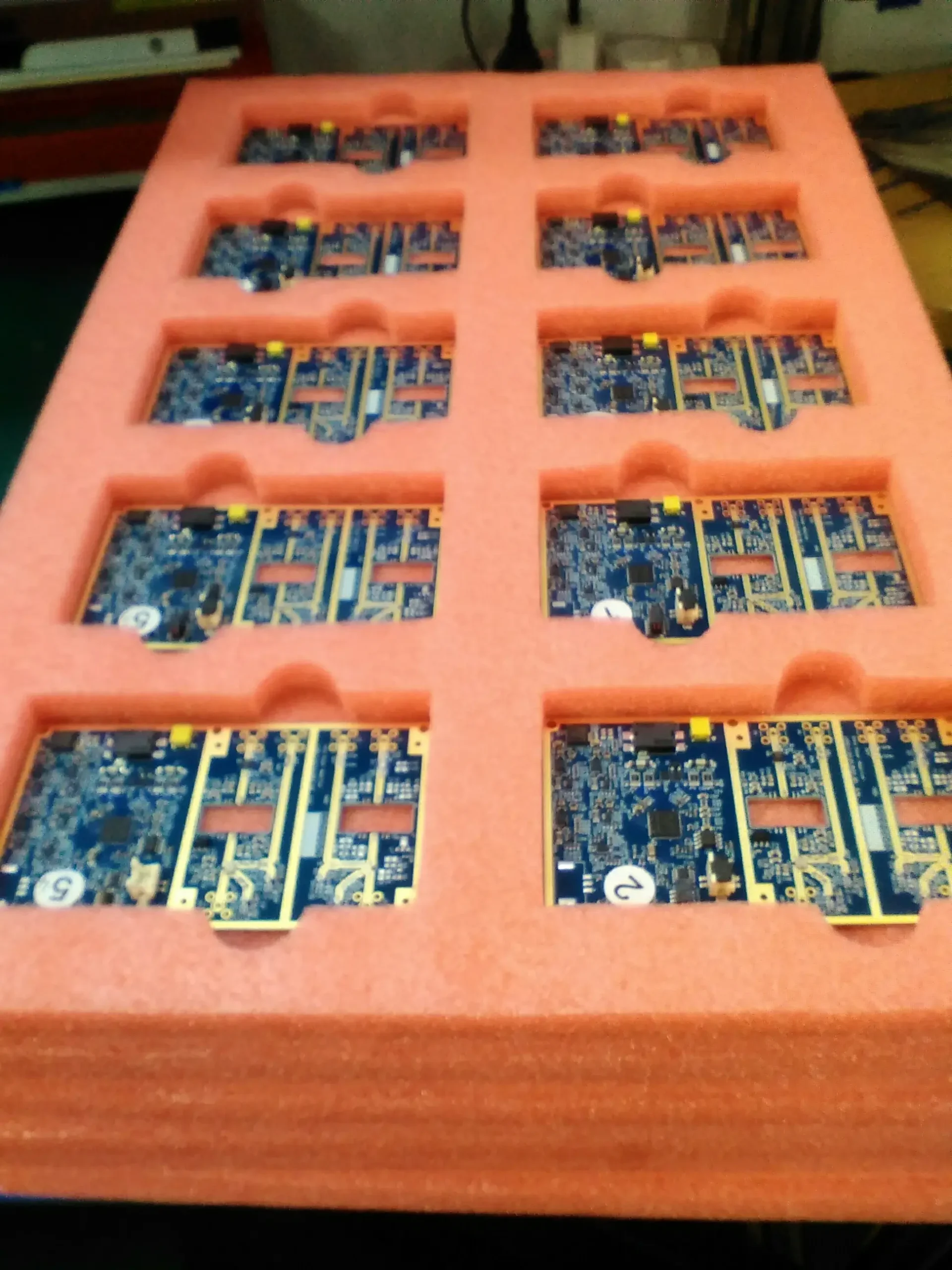

One-stop PCB assembly service.

read more

√ Fulfillment: Turnkey or consigned

√ Quantity: 1-10,000+pcs.

√ Quality Grade: IPC3

√ Lead time: as short as 2 days

√ Other: AOI. X-ray SPI, ICT

PCB has excellent performance in the medical industry. It is usually used as parts of precision instruments.

The aerospace industry uses PCBs as the core part of the control panel. High-quality PCB products make travel safer.

An agile and safe auto system with high-quality PCB products. Professional PCB manufacturer helps automotive manufacturers improve their products.

The new energy industry also needs PCB fabrication and assembly products to finish the transform from natural energy to power.

PCB fabrication and assembly products transmit information for the digital communication industry.

A reliable and advanced PCB fabrication and assembly manufacturer is preferred by any consumer electronics manufacturer.

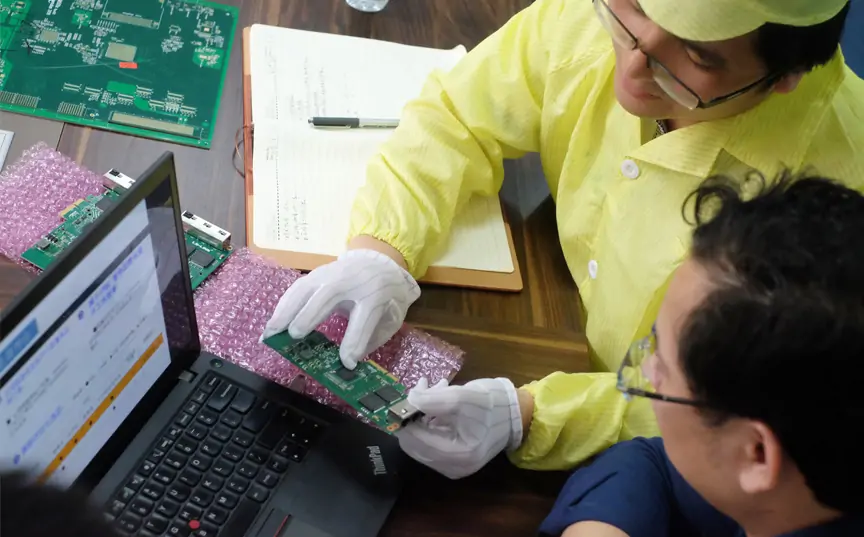

UETPCB provides you PCB Assembly technology from prototyping, low volume to high volume global manufacturing

Management of international standard quality system. High-end automatic precision production equipment.

Service: 24Hours support

Manufacturing: 8/24Hours

Shipping: 3-6 days ship to worldwide.

Abundant experience to avoid quality risks. 6 latest automated lines to handle SMT, through-hole, high-mix technology.

High quality PCB manufacturing & PCB assembly services.

Organize sales department, engineering department, production department, purchasing department, quality Department to hold NPI meeting:

Any questions? Contact us anytime, and we’ll respond to your inquiries within 24 hours.

We specialize in building your pcb prototype and PCB assembly with rapid turn times. All our members are dedicated to providing you with exceptional support.

The industries we serve in aerospace, medical, industrial, LED lighting, consumer electronic markets and more. Our experts are available to consult you for your project.