LED PCB Assembly Supplier

More than 600,000 users worldwide choose UETPCB, because we can give the best solution for customer requirements. All of our products meet international standards. You can choose us with boldness and confidence.

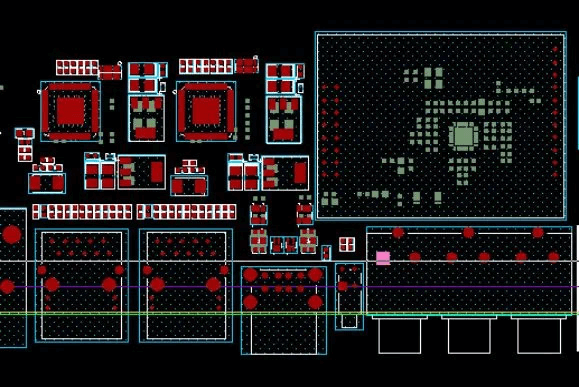

Led PCB board is the core of the led lighting. A chip creates an electrical connection between LED and printed circuit board, and there has a thermal heat sink to dissipate heat.

Because of the well-performance in dissipate heat, the metal core PCBs, especially aluminum PCBs are popular for led PCB board manufacturers.

Usually, the aluminum led PCB board has a thin layer of thermally conductive dielectric material that is more efficient at dissipating heat than traditional PCBs.

| Material | Metal, MCPCB |

|---|---|

| Power | 7 W – 400 W |

| Applications | Downlights, streetlights, floodlights, security lights, etc. |

| Type | Pilot |

| Voltage | 230 Volt |

| Led light pcbs board type | Single-sided, double-sided, multilayer boards |

| Led PCB Thickness | 0.2 mm – 3.0 mm1 |

| Light color | warm white, cool white, bright white |

| Tension Type | DC |

| Frequency | 50 HZ |

| working voltage | AC85-265V |

| Dimming | 2%-100% |

| Basic type | Aluminum plate |

| Shape | Rectangular, square, round |

| Operating temperature | 55 |

| Efficiency | 100 % |

| Warranty Policy | 5 year |

| Color Temperature | 1700-8500K&RGB |

| Min order quantity | 50 |

| Delivery time | 2 – 3 days |

| Production capacity | 10000 per month |

| Material | Aluminum |

| Maximum board size | 585 x 450 mm |

| Diameter | 12 mm |

The led PCB manufacturing process is becoming increasingly popular. It has widely applications in our daily life from computer to automotive industry. This kind of printed circuit board integrates the LEDs(Light Emitting Diodes) onto PCBs (Printed Circuit Board). Aluminium is the idea material for Led circuit board fabrication because of its great heat dissipation, and the high efficiency, low cost, and structural strength make the Led light circuit board become popular for manufacturing industry.

In the led PCB manufacturing process, there are some considerations for high-quality LED PCB fabrication:

LED PCB light has vast applications in different industries because of its low cost and flexible design, and excellent energy efficiency. It usually can be used in industries such as, medical, computer, automotive, and telecommunications industry.

Medical industry: Led light pcb boards used in medical examinations are usually high-powered and made of aluminum with the reason of well heat dissipation.

Computer industry: LED PCB lights are widely used in computer industry because it features great heat sensitivity of computer machinery.

Automotive industry: Aluminium LED PCBs can be used for cars on brake lights, indicators, and headlights. This kind of printed circuit board features durability and competitive prices.

Telecommunications: led light circuit boards are always used in telecommunications equipment because of its excellent heat transfer ability.

The led PCB manufacturing process is becoming increasingly popular. It has widely applications in our daily life from computer to automotive industry. This kind of printed circuit board integrates the LEDs(Light Emitting Diodes) onto PCBs (Printed Circuit Board). Aluminium is the idea material for Led circuit board fabrication because of its great heat dissipation, and the high efficiency, low cost, and structural strength make the Led light circuit board become popular for manufacturing industry.

In the led PCB manufacturing process, there are some considerations for high-quality LED PCB fabrication:

Create the ideal board design layout is the primary step for Led PCB board design, because it usually decides the cost and quality of the final PCBs. Specialized LED PCB designer will design professional Led light circuit board design for customers that can avoid the most defects.

All the Led pcb boards have a orientation from one entry to one exit or most a few. The orientation is that the electricity and data flow. Might a printed circuit board has more than one orientations, so the professional Led PCB board design should ensure all the orientations is from begin to the end.

Every Led pcb board has its specific use, therefore we should consider the subject that might be needed, such as capacitors, resistors, etc. Besides, LED PCB designers should also consider where to place these components, and avoid arranging them on the solder side of the printed circuit board.

Placing components away from the PCB outline is crucial to help manage the LED PCB board design, and protect the printed circuit board from failing in the future. Besides, if you place the component near the PCB outline might cause theses components dislodge from the board.

Placing components according to SMD PCB design rules is a good method to fabricate the high-quality LED PCBs and make it efficient, because the SMD PCB is a standard reference to a set of guidelines for PCB manufacturers to make high-quality products.

The VIAs(vertical interconnect assess) allows manufacturers place components onto the printed circuit board between two or more layers. Placing VIAs away from the end of SMT pads is very important to avoid the PCB defect that the solder to migrate leave from the pad and enter the via space. Therefore, create the distance of 0.025 inches is great between the via and the SMT pad.

We need to definite the net width for the variability of currents.

Different types of Led circuit boards are created for different application, typically, there are 5 types of LED PCBs.

They are flexible Led circuit boards, rigid LED PCBs, hybrid LED PCBs, multi-layer LED PCBs, single-layer LED PCBs.

Led pcb manufacturing process defects

There are malfunction of Led PCB boards might caused manufacturing defects, such as low-quality solder joint connection, material degradation, and contamination. To solute these defects of led light pcb board, you should create the right pad-trace. This can ensure your material is high-quality, and keep clean on the led light pcb board surface.

The second reason why your Led PCB board fail is caused by environmental factors. They are heat, dust, moisture, and physical shock.

Non-specific design is also an important reason to make malfunction of your Led PCB board. You should consider in component selection, material selection, PCB layout, and design verification.

LED PCB assembly results from the development of PCB technology: Light PCB assembly is the process of soldering light-emitting diodes and small chips together, which emit light when electrically connected. Because Light PCB assembly has excellent design flexibility, you can integrate them into various lighting applications. We are your preferred manufacturer of LED PCB Assembly. By providing LED PCB assembly services, UETPCB has participated in thousands of LED lighting projects.

At UETPCB, you can learn about Light PCB assembly. Our guide covers all aspects of LED PCB assembly-including specifications, BOM, assembly technology, and more. More importantly, you will learn the Light PCB assembly solutions and packaging process. At the end of this guide, you will become an expert in the Light PCB assembly process.

FR-4: FR-4 consists of glass and epoxy resin and is one of the most common core materials for custom led pcb boards. It is flame retardant but is not particularly effective at transferring heat.

Epoxy resin: Epoxy resins are another common choice for custom led pcb boards. They are not as durable as other core materials but are less expensive to manufacture.

Metal Cores: Metal core PCBs are usually aluminum and other metals and laminated with copper. These materials can be used in heat transfer applications and provide excellent thermal conductivity and electrical insulation.

Because of the vital role of heat transfer in Led circuit board applications, metals, especially aluminum, are the most common Led light pcb board materials.

These boards sit on an aluminum alloy base, typically composed of aluminum, magnesium, and silicon. Aluminum LED PCB boards are used in many applications, including flexible aluminum, hybrid aluminum, and multilayer aluminum.

Aluminum custom led pcb boards consist of multiple layers.

Base layer: The base layer consists of an aluminum alloy board

Thermal barrier: The thermal barrier of the aluminum LED PCB board consists of a ceramic polymer that protects the board from thermal and mechanical damage.

Circuit layer: This layer contains copper wires arranged according to the circuit design of the custom led pcb boards.

The custom led pcb boards has different numbers of these layers depending on the design of the custom led pcb boards.

Any questions? Contact us anytime, and we’ll respond to your inquiries within 24 hours.

We specialize in building your LED PCB with rapid turn times.