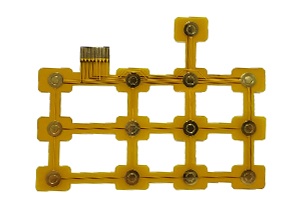

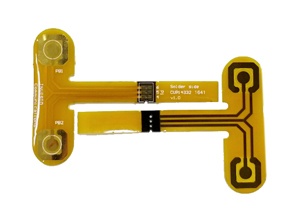

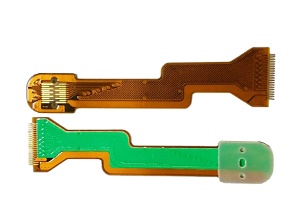

Our Custom Flexible PCB Service

UETPCB provides you with flexible PCB customization services.

Flexible PCB has exceptional bending performance. It opens up many possibilities in electronics.

We provide custom flexible PCBs of various shapes, sizes, and functions. Please let us know your needs, and we’ll provide customized solutions.

Custom Flexible PCB Manufacturing Capabilities

| Customization options | parameter |

|---|---|

| Layer | 1-12layer |

| PCB thickness (without stiffener) | 4-40 mil |

| Tolerance of single layer | ±1.0 mil |

| Tolerance of double‐layer (≤12mil) | ± 1.2 mil |

| Tolerance of multi‐layer (≤12mil) | ± 1.2 mil |

| Tolerance of multi‐layer (12mil‐32mil) | ±5% |

| Tolerance of board thickness (including PI stiffener) | ±8% |

| Min. board size | 0.0788” *0.1576” (without bridge) 0.3152” * 0.3152” (with bridge) |

| Max. board size | 8.668” * 27.5” |

| Impedance control tolerance | ±5Ω (≤50Ω), ±7% (>50Ω) |

| Min. coverlay bridge | 6 mil |

| Min. bend radius of single layer | 3‐6 times of board thickness |

| Min. bend radius of double‐layer | 7‐10 times of board thickness |

| Min. bend radius of multi‐layer | 10‐15 times of board thickness |

| Min. mechanical drill hole | 4 mil |

| Inner Layer Trace / Space | 2 / 2 mil |

| Outer Layer Trace / Space | 2 / 2 mil |

| Solder mask color |

Yellow, white, Black |

| Surface treatment | ENIG |

| Laser accuracy (Routing) | ±2 mil |

| Punching accuracy (Routing) | ±2 mil ‐ ±6 mil |

Flexible PCB Design Service

Determine your needs

We communicate your needs and design requirements with you. Including circuit layout, size requirements, functional requirements, etc.

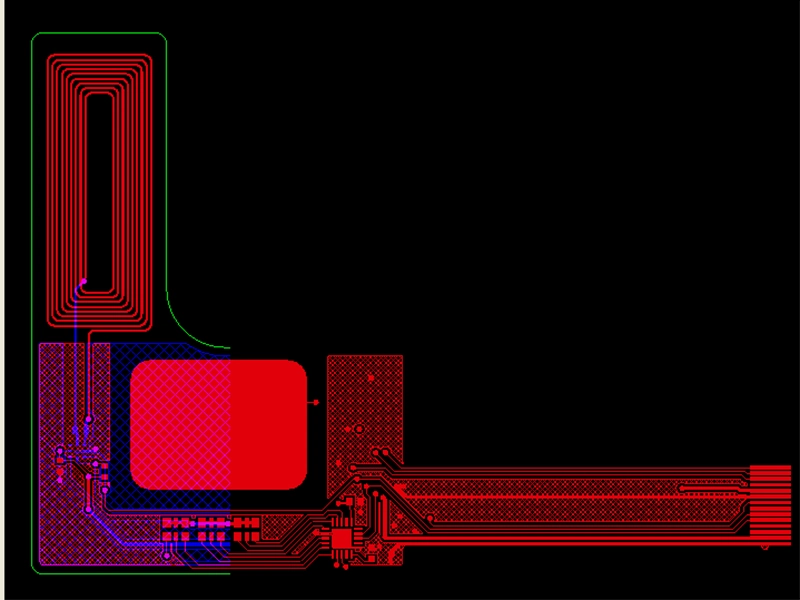

Flexible PCB design

Use professional design software to design PCB and draw preliminary design sketches.

Optimization and adjustment

We will communicate with you continuously to ensure that the PCB layout is reasonable.

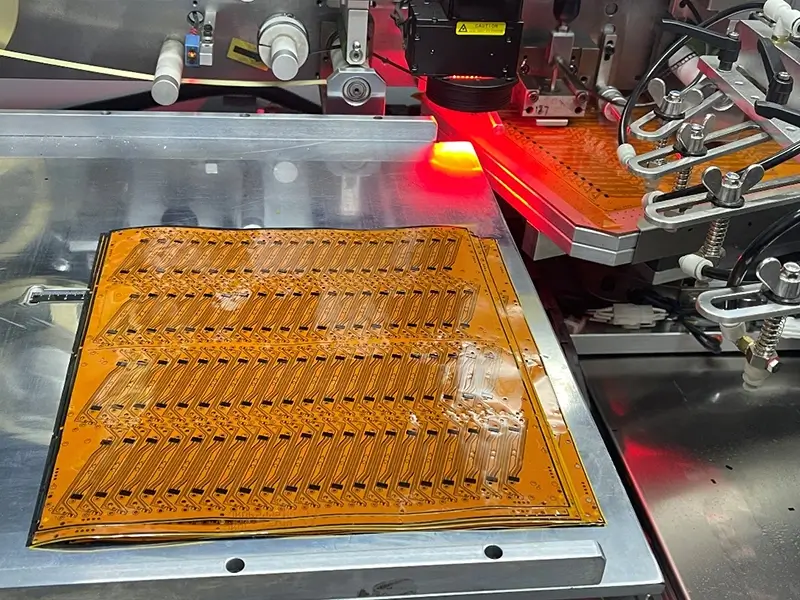

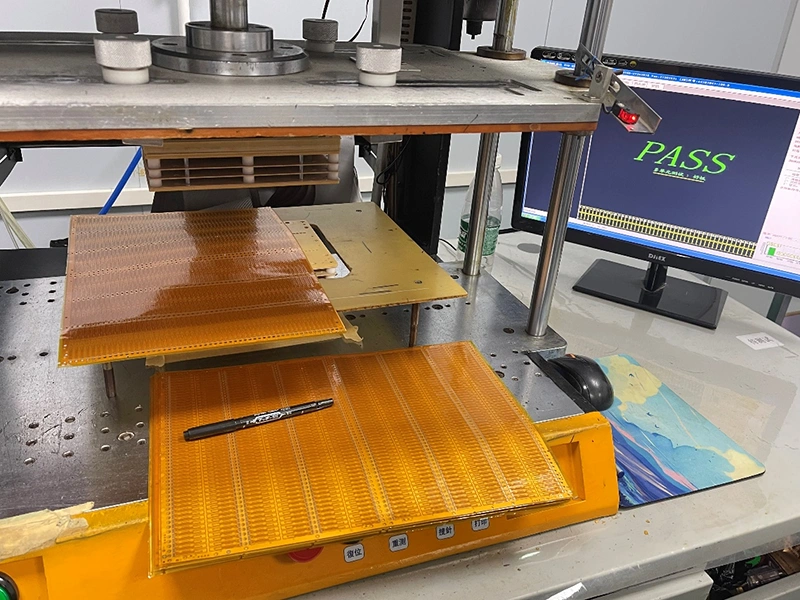

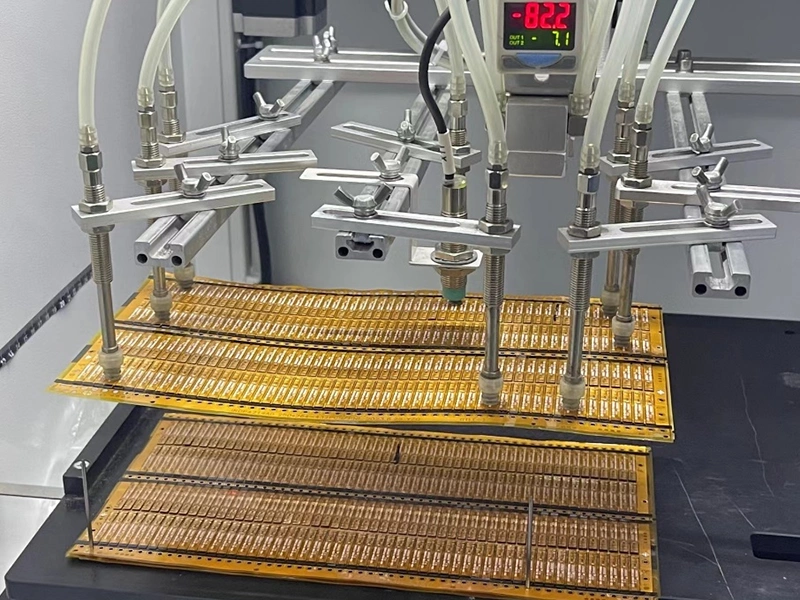

Sample production and testing

Make samples for actual testing and verification. Ensure that the PCB can work properly and meet performance requirements.

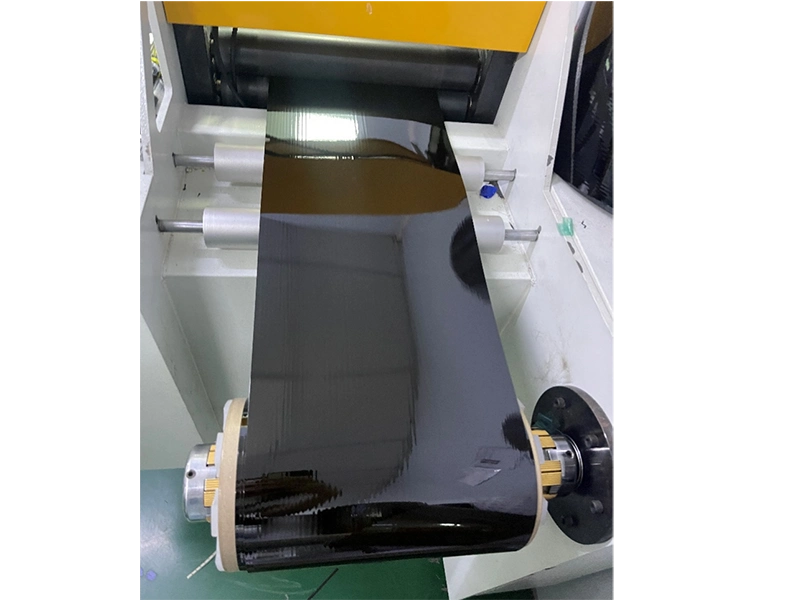

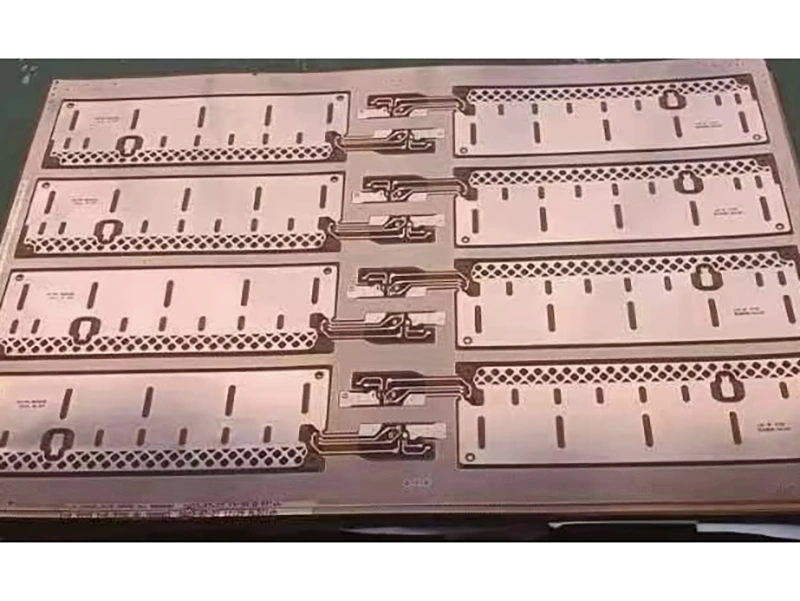

Flexible PCB Manufacturing

Once the sample passes the test, we start mass production of PCB.

Ensure that it is delivered to you on time and maintain stable product quality.

Flexible PCB delivery

We will keep in touch with you after you receive the goods. Answer your feedback questions. Ensure that you are satisfied with the final product design.

Advantages of Flexible PCB

1. Bendability:

Flexible PCB can be used flexibly in applications that require bending. It can adapt to irregular shapes and curved designs.

2. Space saving:

Due to the thin design of flexible PCBs, a lot of space can be saved.

3. Weight reduction:

Flexible PCBs are lighter and can reduce the overall product weight compared with rigid PCBs. Therefore, they are suitable for lightweight design.

4. Reliability:

Flexible PCB reduces the connection points. This cuts the failure rate and boosts product reliability.

5. Cost reduction:

The cost to manufacture flexible PCBs is low. The assembly process can be simplified, saving costs.

6. Strong adaptability:

Flexible PCB is suitable for many uses. These include curved and wearable electronic devices.

Flexible PCB Applications

Flex PCB has its own place of application in various industries, from LCD to the automotive field. It is usually used as a connector in different sectors. The flexible PCB board is flexible and space-saving. So, it is prevalent in narrow spaces where the capability of rigid PCBs is limited.

- Electronic assemblies: Flex PCB boards can be used as passive wiring structures. They enable the connection of electronic parts through their flexible design. For example, capacitors, resistors, and integrated circuits are noteworthy.

- Automotive field: Flexible PCBs can be used in under-hood controls, apparatus panels, or ABS systems.

- Computer peripherals: Flexible PCBs are also prevalent on the moving print head of printers. They submit the signals to move arms to finish the final printing.

- Manufacturing & medical devices: Flex circuit boards established the interconnections in the compacted package. Because of its flexibility, they are well-performing in these devices.

Consumer electronics

Smartphones and tablets, smart watches, fitness trackers, virtual reality devices, digital cameras

Medical devices

Glucose meters, electrocardiographs, wearable health monitoring devices, pacemakers, neurostimulators,

Endoscopes, ultrasound probes

Automotive electronics

Airbag sensors, driver assistance systems, navigation systems.

LED headlights, interior lighting

Industrial applications

Robotics, PLCs, HMIs, power tools.

Aerospace

Flight control systems, satellites, spacecraft

Communication equipment

Antenna modules, Base station equipment, Fiber optic communication equipmen

Home appliances

Smart thermostats, smart locks, smart bulbs

Washing machines, refrigerators, microwave ovens

New energy

Solar panels

Electric vehicles

Wind power generation equipment

FAQs

There may be some misunderstandings against Chinese PCB manufacturers. Some may think that they provide cheap but inferior products. Actually, no matter what country it is, a high price doesn’t always mean high quality. It depends on various factors. However, in most cases, a high price may determine the high quality of the product. They typically come with durable PCB materials and sophisticated PCB designs. In addition, they resemble excellent PCB manufacturing and assembly equipment. If the PCB company has its R&D basic, it might price relatively high for its products.

There are a few reasons for the lower product prices of Chinese manufacturers. It is not the unreliable product quality or inferior PCB fabrication and assembly equipment but the local market and policy. Reasons why you should choose Chinese flex PCB manufacturers are:

A crowded market stimulates advanced technology

With over 15 years of experience, the Chinese PCB market has a well-established system of PCB services. Fierce competition in this market encourages Chinese PCB manufacturers. It enhances its manufacturing technology to offer competitive products continuously. However, market dynamics make prices generally lower than in Europe.

Lower-cost labour with efficient production

China’s competitive employment market also produces lots of efficient labour with lower costs. China nowadays can achieve mass PCB manufacturing and assembly in a highly efficient way. It lowers the production time and cost. Besides, it provides an affordable price with the same quality as other developed countries.

High-quality PCB service

As the PCB market matures, Chinese PCB manufacturers can provide satisfying services. Their full-service includes full-service from PCB manufacturing to deliver only your requirements online. The Internet provides a chance for every PCB company to buy PCB online.

Flex PCBs are usually made of materials according to their applications. Various materials can be used to produce flexible printed circuit boards. For example, Teflon, polyimide, FR4 epoxy, or other laminates that combine glass with resin coatings are noteworthy.

Using PCB materials to design the flex PCBs has some considerations.

Here are them:

- Dielectric

- Mitigated loss factors

- Flame retardancy

- Higher temperatures for glass transition

- Thermal performance

- Dimensional stability

Flex PCB thickness and flex PCB bend radius are necessary for PCB design. It dominates the quality of flex PCB design. Usually, the flexible printed circuit board thickness is 0.05mm to 0.8 mm. A flex-printed circuit board’s bend radius should be at least ten times the material thickness. Maintaining this radius at least 500 um away from plated through holes is crucial. These holes should include reliefs for slits in the circuit. Additionally, incorporating tear stops is essential for reinforcement.

We’re Here To Help You

Any questions? Contact us anytime, and we’ll respond to your inquiries within 24 hours.