An LED PCB is very popular in modern electronics. The PCB typically provides the foundation for mounting LEDs, making lighting more efficient and durable.

In this article, you will learn what LED printed circuit boards are, their benefits, and their making process. After learning about their applications, you will get hints about design considerations. Overall, this article will be convenient if you plan to do LED business. For enthusiasts, you can get some ideas on how to make circuit boards with LED.

What is An LED PCB?

LED stands for Light-Emitting Diode. When a printed circuit board controls an LED, the device is called an LED PCB. A circuit board with LED generally features a base, conductive, and thermal layer; the structure typically depends on the design.

LED PCBs can be made of various materials. However, Aluminum is prevalent in this case. As you know, Aluminum is an excellent conductor of heat. Engineers considered these features and implemented them on LED-printed circuit boards. Therefore, LED PCBs can quickly dissipate heat and ensure the device works perfectly.

PCB LED light is prevalent in various lighting systems and displays. It plays a crucial role in modern electronics. In the later sections, you will learn more about its applications.

Benefits PCB LED Lights have replaced LCD PCBs in many applications. There are several reasons behind this. However, the most common benefits of PCB LED lights are:

(1) LEDs usually generate heat during operation. If you fail to dissipate this heat, the LED loses its performance and lifespan. LED PCBs, in this case, manage heat efficiently.

(2) The LED circuit board also ensures the device’s durability. The materials used in this device resist moisture, dust, and vibrations.

(3) One of the best things about LED PCBs is their energy-saving ability. They reduce energy loss and make your device more energy-efficient.

(4) LED-printed circuit boards are incredibly compact and lightweight. You can install them anywhere.

(5) PCB LED design is highly customizable. You can design them for specific use.

How Are LED PCBs Made?

The manufacturing process of LED PCBs is relatively simpler than other high-frequency PCBs. It typically involves four key steps.

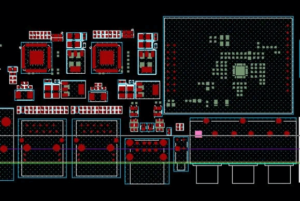

Step #1 LED PCB Design

First, the process will begin with your plan and design. You will then create the strategy and design of the circuit layout, which should meet your project’s specific requirements. This step mainly ensures the proper placement of the LEDs and other components.

Step #2 Creating the Layout

Once your design is ready, you must prepare the circuit layout. In this case, you can use PCB design software to create the conductive paths accurately. Later, you will transfer this design to the PCB material.

Step #3 Choosing the Right Materials

Once your design and layout are ready, it is time to choose the LED PCB design. You have several options for a material. Aluminum is the most common material in this case. This material is excellent at dissipating heat and is incredibly light and cheap.

On the other hand, FR4, ceramic LED PCB, copper-baed PCB, and flexible LED PCBs are also common. Each material has its unique benefits and limitations. You will have to choose one based on your project needs.

Step #4 LED PCB Manufacturing

The actual production typically involves a series of steps. Some crucial steps include etching the circuit, drilling holes, and adding a solder mask. The final task is to mount the LED on top of the board. Later, you must test these PCBs and approve their final shape. These LED PCBs are then sent to assembly lines to create various electronic gadgets.

Wide Applications of LED Printed Circuit Board

People need LED PCBs in sectors where electronics are used. This means that where there are electronics, there are the LED PCBs. Each electronic device must have a display or indicator that helps you identify the work completed. Some of the most popular uses of LED-printed circuit boards are:

(1) LED PCB is prevalent in lighting systems. It is used in residential, commercial, and even industrial lighting. It is the most efficient solution for homes, offices, and factories.

(2) LED PCBs are also prevalent in the automotive sector. They are required for headlights, taillights, and many interior lights.

(3) LED PCB is also essential for creating screens and displays. They are found on televisions, monitors, and many ad billboards.

(4) PCB LED light is also prevalent in medical industries. Surgical lights, sensors, and many diagnostic tools need it.

(5) LED PCBs are also used in many consumer electronics. Smartphones, cameras, and wearable gadgets need them to operate smoothly.

(6) Different types of LED PCBs are used in the aerospace, defense, marine, automotive, research, and manufacturing industries.

LED PCB Design Consideration

When designing an LED PCB, you must come up with proper planning. Later, we will create a detailed article about LED PCB Design. In this section, you can look at some key factors when designing an LED PCB.

Type of Connections

There are two types of connections: series and parallel. Series connections are simple but may fail if one LED stops working. Parallel connections are relatively complex and much safer.

Row Scanning

Row scanning typically activates one row of LEDs at a time. This technique reduces the connections and components needed and is often used in LED displays and panels.

Thermal Management

As you know, LEDs produce heat simultaneously. So, when designing an LED PCB, you must apply proper thermal management techniques. You can use suitable materials to dissipate heat quickly.

Multiplexing and Matrixing

These two terms are critical in LED PCB manufacturing. Multiplexing typically controls multiple LEDs with fewer connections, while the Matrixing method arranges LEDs in rows and columns. These techniques significantly reduce the production cost.

Type of Materials

The next factor that comes up is the selection of the right material. In this case, you can use various types of materials. However, Aluminum is the most popular one here. As you know, Aluminum is a great conductor of heat. Therefore, it can quickly dissipate heat.

Sum Up!

LED PCBs are an essential component of modern electronics. Using PCBs to control LED lighting has several benefits, including high efficiency, low energy cost, and proper heat dissipation. However, you must consider the proper LED PCB design to ensure those benefits. Appropriate material selection, layout design, and techniques are crucial.

If you have any questions, feel free to contact us. UETPCB is always ready to help.