Printed circuit boards may come in various types and forms. The main reason behind this diversity is to fit them in different electronic gadgets. Rigid-flex and flexible PCBs are among the most common types. However, when it comes to which is better, many questions arise. Thus, the topic, “Rigid-flex PCB vs Flexible PCB: Which is Better?” becomes essential.

Both of these PCBs have their specific benefits and limitations. In this article, you will go through each of these types. And then, you can justify which type suits your project needs.

What is Rigid-Flex PCB?

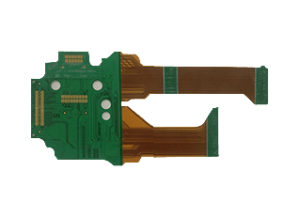

As the name suggests, these PCBs combine rigid and flexible parts into a single board. The rigid parts typically provide structural support. It is mounted on the main casings and screwed on the casing. On the other hand, flexible ones offer bending and folding. This hybrid design typically makes them suitable for complex and compact devices.

These PCBs are widely used in aerospace, medical, and consumer electronics industries. The combination of these two PCBs makes seamless connections between different components. Because of this, you can eliminate the need for connectors and cables.

Benefits of Rigid-Flex PCB

(1) This PCB’s best and most important benefit is that it opens up vast possibilities for making different electronic gadgets. The best example could be your laptop or smartphone. If you disassemble them, you will find that a motherboard is connected to various components. Flexible PCBs typically make this connection. Therefore, these PCBs play a crucial role in reducing the size of electronic gadgets.

(2) Using these PCBs saves a lot of space in electronic gadgets. It is ideal for compact devices since they can bend and fold.

(2) They withstand mechanical stress better than traditional PCBs.

(3) Using these PCBs doesn’t need extra connectors and cables. Therefore, you can make lighter and smaller devices.

(4) Using rigid-flex PCBs doesn’t need extra connections. Therefore, you can ensure fewer points of failure.

(5) Since cables or connectors are unnecessary, this PCB reduces signal loss. This way, you can improve the signal integrity of your gadget.

Limitations of Rigid-Flex PCB

(1) Rigid-flex PCB needs a complex design process. Thus, making these PCBs is more expensive than traditional options.

(2) These PCBs need longer production time.

What is Flexible PCB?

As the name implies, these PCBs are flexible or bendable. They are often made of polyimide. Flexible PCB is ideal for use in tight spaces. However, you can not expect much strength from these PCBs.

Flexible PCBs are used in portable, car-electronic, and foldable devices. Their flexibility makes them ideal for this use in dynamic and compact environments.

Benefits of Flexible PCB

(1) Flexible PCBs can adapt to tight spaces. The best thing about this PCB is that it performs well in dynamic applications.

(2) These PCBs don’t need many connections, significantly reducing writing errors. Also, you can get better-quality signals.

(3) Flexible PCBs are usually lightweight, making your device more compact and lightweight.

(4) Mechanical connections are necessary when using flexible PCBs. This improves the durability of your device.

(5) Most flexible PCBs use thin material, which means they have a lower SAV ratio. Because of this, they can quickly dissipate heat.

(6) Flexible PCBs need fewer materials. Thus, the total cost of these PCBs is lower than that of rigid PCBs.

Limitations of Flexible PCB

(1) Flexible PCBs are fragile. If you bend them excessively, they will eventually damage you.

(2) Flexible materials are comparatively expensive. Although compared to rigid-flex PCBs, these PCBs are cheaper. However, flexible materials are typically expensive when you only consider the material.

(3) Handling and assembling flexible PCBs is comparatively complex. Therefore, an expert is always needed.

Rigid-Flex PCB vs Flexible PCB: Which is Better?

You have gone through the pros and cons of each type of PCB. Now, the question is, which is better? You must explicitly know what you will do to get this answer. Let’s highlight why and when you should choose between rigid-flex and flexible PCB to make it easy.

Moreover, when you decide between these two PCBs, you must consider several factors. First, you must know your project or design requirements. Later, you can consider the cost, efficiency, and performance. Which one could provide a more durable solution? Which would produce less heat? Which PCB would make the assembly easier?

Why and When Choose Rigid-flex PCB?

Rigid-flex PCB is an excellent choice if you want your device to be more compact and reliable. They are perfect for use and need both durability and fewer interconnections. You can use rigid-flex PCBs in multi-layered designs. You can also consider these PCBs for tight spaces.

For example, your laptop or smartphone needs high-frequency and better signals. The main motherboard connects many components. In this case, a rigid-flex PCB plays a crucial role. The PCB that connects the display or speaker is usually flexible, while the leading motherboard is entirely rigid. This lets you consider whether your device needs to connect separate components.

Why and When Choose Flexible PCB?

Flexible PCBs, on the other hand, are more suitable for devices that need frequent movement. If your device frequently involves bending or moving, it will need flexible PCBs. Examples include wearables, folding gadgets, robot hands, and automation parts.

Summary

Rigid-flex and flexible PCBs are both popular in modern electronics. What makes them different is their construction and specific use. In one simple sentence, one can bend, and the other can semi-bend. Semi-bend means that the rigid-flex PCB has two parts: one can bend while the other can’t.

Whether rigid-flex or flexible PCB, each is suited for a specific use. They are both perfect for compact, reliable, and high-performance devices. They both are used in laptops, smartphones, machines, auto parts, aerospace, robot hands, and many more. Although they are costly, they offer many benefits.

When choosing between them, you must first understand your project needs. As mentioned in this article, “rigid-flex PCB vs. flexible PCB,” rigid-flex PCB is better for multi-layered designs. It does an excellent job for high-performance devices. On the other hand, flexible PCBs are often used in tight spaces. They do a great job in devices that involve frequent movement.

After all, if you have any questions, don’t hesitate to contact our customer support team. UETPCB is a leading manufacturer and assembler of all types of PCB and electronic gadgets. For more information, contact us today!