Pcb prototype service introduction

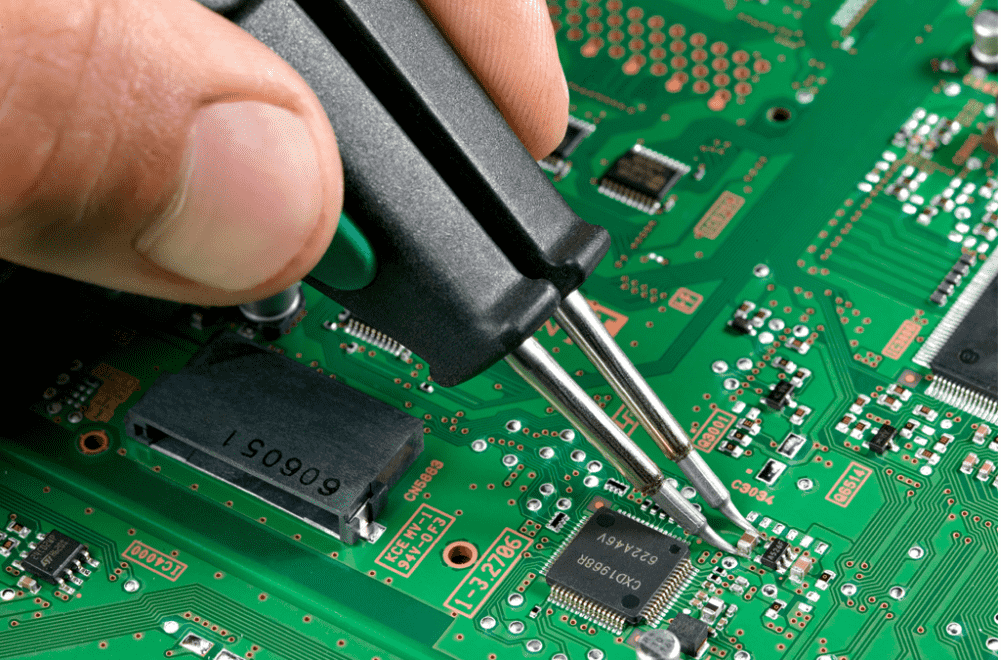

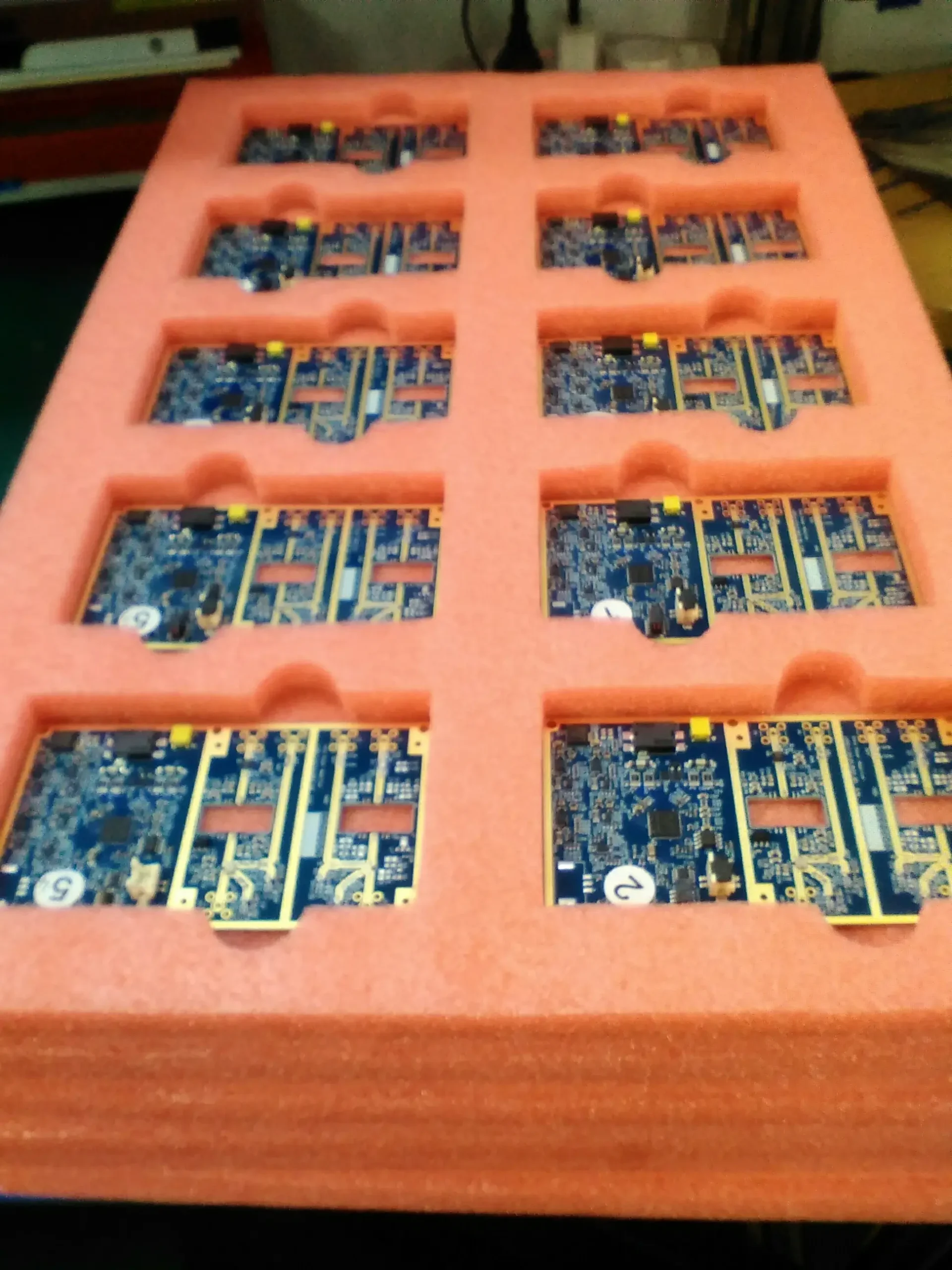

Component assembly

UETPCB is a professional pcb supplier & pcba manufacturer in Shenzhen. We focus on providing high-quality PCB assembly services. As a reliable PCB supplier, we provide one-stop service from PCB manufacturing to assembly. Our professional team has the experience and skills to meet the needs of various industries. Our goal is to be your preferred partner in China PCBA manufactory. If you need quality PCB assembly services, please contact us.

✅ High-density design: supports smaller and lighter electronic devices (such as mobile phones, smart hardware);

✅ Automated production: fast speed, high precision, suitable for mass production;

✅ Cost-effectiveness: reduces labor and material waste, lowers unit cost;

✅ High-frequency performance: shortens signal path and improves high-speed circuit stability.

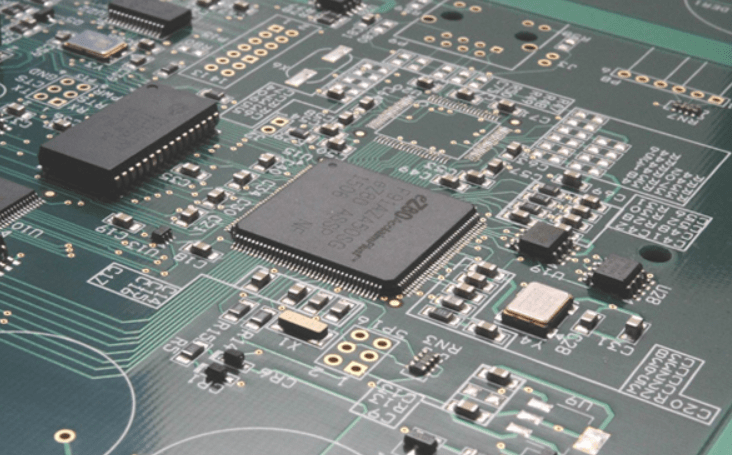

Step 1:Creating a designed layout on the copper-clad laminate

Step 2:PCB manufacturers will etch or remove excess material from inner layers to reveal images and pads.

Step 3:Laminating printed circuit board materials at high temperatures for creating the PCB layer stack up

Step 4:Creating mounting holes, through-hole pins, and vias on PCB

Step 5:Etching and removing the excess copper of the surface layer to reveal images and pads

Step 6:Placing plating pin holes and via holes

Step 7:Creating a protective coating or solder masking on the surface

Step 7:Silkscreen printing, logos or other markings, and installing polarity indicators on the surface

Any questions? Contact us anytime, and we’ll respond to your inquiries within 24 hours.

We specialize in building your pcb prototype and PCB assembly with rapid turn times.