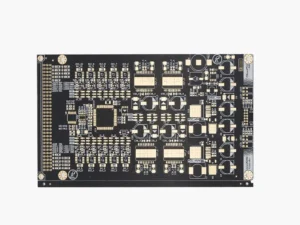

Nowadays, electronics are running the whole world. With the development of this field, many industries are emerging. You can consider medical, automotive, defense, and aerospace. Everything needs electronic devices and control systems to operate. Consequently, PCBs are the backbone or heart of every device used in these sectors. Thus, prototype PCB assembly is a critical topic to discuss.

The electronics industry is typically driving the evolution of electronic devices. They compete to devise new solutions. In this case, UETPCB is one of the best manufacturers of these companies. They provide services from making PCB prototypes to prototyping PCB assemblies.

Prototype PCB Assembly and Manufacturing: Role in the Electronics Industry

All electronics industries heavily rely on printed circuit boards (PCBs). It plays a crucial role and is the basis of all electronic devices.

PCB prototyping is the process of creating a printed circuit board (PCB) before mass production. There is a purpose in creating a prototype. You can check if the PCB functions properly or if further modifications are needed.

The rigorous modification and development typically improve the quality of the final product. It ensures that the PCB meets your project needs. Besides, you can also reduce the risks of losses.

PCBs ease connections between electronic components. It enables the device to operate properly. There are many benefits associated with creating a PCB prototype.

First, you can create and develop new things through it. Second, you can edit things to gain better control over them. If there are any errors or mistakes, you can correct them. Overall, with prototype PCBs, designers can try different versions of a product and choose the best one.

At UETPCB, we create prototype PCB assemblies using modern tools and machines. We can ensure that our PCBs remain competitive in the market.

Prototype PCB Assembly and Manufacturing Process

The prototype PCB Assembly and Manufacturing processes depend on the type of PCB. Sometimes, the method also depends on the complexity of the printed circuit board (PCB). Perhaps you need general customization. It includes layer counts, traces, components, and other elements. In this situation, you may prefer to use the quick customization feature.

If necessary, you must change the core design. In these cases, you must go through the entire design and development process. Expert engineers use rapid prototyping to resolve these issues.

PCB Prototype: The Easy Way

The easiest way to customize your PCBs is by using virtual applications. It could be the website or customer support consultation.

Step #1: Understanding the online custom tools

Using online custom tools is the easiest way to customize your printed circuit boards (PCBs). Many PCB assembly manufacturers utilize their unique applications. UETPCB is no exception. The company also uses modern tools to customize your PCB design.

If you understand how PCB works, it is easy for you to customize your PCB using online tools correctly. Still, it may lead to errors. To address these issues, you can first seek advice from experts.

Step #2: Uploading the Garbour File

The Garbour file is the blueprint of your PCB. It contains the details of the design, including holes, layers, and other essential features.

The Gerber file typically contains the layout information of your PCB. Once its design is ready, you can upload it online.

Step #3: Choosing the Board Type and Other Specifications

Once you have uploaded the Gerber file, select the type of your Printed Circuit Board (PCB). Your PCB board could be single-sided, double-sided, or multi-layered.

You can also choose special types of PCBs. Examples of well-known special types of PCBs include HDI, flexible, and rigid-flex PCBs. In addition to these PCBs, you also have options for aluminum, high-frequency, thick copper, metalcore, and many more types of PCBs.

The next part is to choose the shape of your PCBs. Set the shape according to your device and the allotted area for the PCB.

Step #4: Waiting for Expert Approval

After submitting the design, the tech team will review your file. They check the design and confirm whether it can be made or not. If there are any issues with the design or if any changes are needed, the team will contact you. After approval, your order will move to the next step.

Step #5 Final Production

Select a surface finish, such as HASL, ENIG, or immersion silver. Additionally, options for solder masks and silkscreens are also available.

You may add your logo or choose a color for the label. Overall, online customization tools give you an instant quote. Anyone can design it with basic knowledge, watch pricing, and save time.

Core Customization

Core customization enables you to create a board tailored to your specific requirements. If you want to change the design, you can make it and choose custom layers to enhance performance. It is an improvement process in PCB manufacturing.

Step #1: Designing

Firstly, it starts with design changes. If your design requires any customizations, make them accordingly. Adjust the size and shape of your PCB and relocate accessories as necessary to optimize the layout. Thus, you can save space and minimize errors. Additionally, you can add a heat sink or shields to the board, as they protect it from heat and noise.

Step #2: Approval & Modification before prototyping

After approval, make initial choices for making an appropriate prototype. For optimal functionality, use materials that enhance performance and dissipate heat effectively. High-frequency printed circuit boards (PCBs) use Teflon or Rogers materials.

Use EMI shielding to cut large electrical noise. Additionally, you can use copper layers to enhance quality. You may also consider silver or gold plating for enhanced conductivity. These changes enhance your device’s strength, speed, and reliability.

Step #3: Prototyping

Based on your design and approvals, it is time for you to create your first PCB prototype. It is necessary to test how they function in the real world. It helps you justify everything and functions as planned. Prototyping also includes component assembly. It is, in fact, the physical form of the final product. Prototyping is necessary to identify hidden flaws and test performance.

Step #4: Testing & Modification

Test the prototype to see if it works accurately. If it doesn’t work well, modify the customization and make adjustments to create a better version.

You can utilize multiple custom layers for various purposes. For example, one layer is for handling signals, and another is for carrying power supplies.

Furthermore, you can add ground or power planes to enhance performance. These layers will help keep the circuit and device safe.

Step #5: Rapid Prototyping

Rapid prototyping is an iterative process. It includes three phases: prototyping, review, fine-tuning, and iteration.

Once your prototype is tested and needs modification, you must make the modifications accordingly. And then, you must review it for further modification. This iterative process is crucial to achieving the highest quality of the product.

You can check if earlier problems are resolved and the new changes work as expected. This step repeats until the design is perfect.

Step #6: Final review and ready for bulk production

If your product is prepared after rapid prototyping, conduct a final review to confirm its readiness for production. Engineers thoroughly inspect everything and prepare it for mass production.

You can use FR4 high-performance materials for these printed circuit boards (PCBs). It is a cost-effective choice with fantastic mechanical and electrical properties. If everything is perfect in terms of mechanical flexibility, then it represents the final design.

Custom PCB Manufacturing at UETPCB

Finding the right prototype PCB Board Manufacturers is the most crucial part of the journey. Before making a decision, consider the prototype PCB assembly services offered by manufacturers.

UETPCB is one of the top PCB and PCBA manufacturers in China and globally. With over 15 years of expertise, they provide one-stop solutions for PCB manufacturing. Compared to their PCB prototype services, their offerings are extensive.

UETPCB offers services from PCB design to box build-up assembly. By 2025, the company had secured over 5,000 clients worldwide.

Comprehensive PCB Prototyping and Assembly Services

UETPCB offers a wide range of PCB prototyping and manufacturing services. These PCB board prototypes include single-layer, double-layer, multilayer, rigid, and flexible boards, among others. There are also advanced PCBs, such as High Tg, metalcore, and Halogen-free PCBs. Apart from this, they provide turnkey PCB assembly by sourcing quality components. Additionally, UETPCH offers wire harnesses, high-volume and low-volume assembly, BGA, and other specialized assembly services.

Manufacturing Abilities

UETPCB boasts strong manufacturing capabilities, offering advanced solutions and an expert team. They support a wide range of PCBs for mass production and shipping with good care. The company ensures fast turnaround while assuring high quality at competitive pricing.

They utilize modern technologies with six automated lines to handle SMT, THT, and other processes. Their experts utilize HASL, OSP, Immersion Tin, Immersion Silver, and ENEPIG surface finishing. Different materials require specific finishing processes. UETPCB ensures the particular use of these finishes for optimal performance.

The quality control level is higher, as they are certified by ISO, CE, IATF, RoHS, and other relevant standards. Also, the company has excellent customer support. As a result, UETPCB is a complete package for PCB manufacturing and assembly. Considering these factors, you can rely on them, as they will ultimately benefit you.

Contact us Today

You are now familiar with the entire process of creating PCB prototypes and manufacturing them efficiently. If you have any questions, please don’t hesitate to contact us Today. Our team is ready to assist you. Start your journey with UETPCB to experience something new.