In space, it isn’t easy to work as a human. We cannot live without oxygen. Besides, our bodies can’t endure harmful radiation. We send robots and pre-programmed machines into space to perform specific tasks. In this case, aerospace PCB assembly plays a role in space and aviation technology.

Since the space is not quite favorable, everything we send there must be durable. The PCBs must function in high radiation. Besides, it must endure strong vibrations and varying temperatures. You must consider that in space, there is no air. So, there is no medium for heat dissipation. Therefore, protecting PCBs from radiation and a harsh env is critical here.

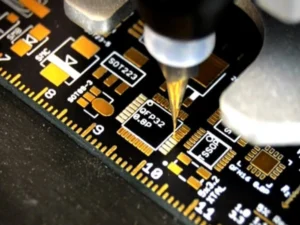

Why is efficient aerospace PCB assembly important? You need it to ensure that the planes and spaceships are safe and function properly. You must also make sure that strict standards for quality, speed, and safety are met. They are crucial for controlling movement, managing power, navigation, and communication. You know, one mistake can cause a lot of big problems. Because of this, every aircraft PCB assembly has to be carefully planned, built, and tested.

Aerospace PCB Assembly Requirements for Radiation and Extreme Environment Protection

Aerospace PCB assembly must follow strict quality standards. It might include how you design and make it. These standards are typically not the same for the items we use on a daily basis. IPC and AS/EN specifically talk about the aerospace needs.

At UETPCB, aerospace PCB assembly is tested in a virtual environment. The company also offers authentic test certificates and documents.

#1 Following Proper Standards for Aerospace PCB Assembly (IPC, ISO, AS/EN 9100)

Aerospace PCB assembly mainly follows IPC, ISO, and AS/EN 9100 standards. There are specific rules for the design and manufacturing.

You can be sure of the quality and accuracy of PCB assembly if you follow these rules. Most of the time, IPS standards cover the design and production methods. AS/EN 9100 is primarily intended for the aerospace industry. When all these standards are combined, they ensure the highest level of quality.

#2 Choosing the High-Quality Materials

For space applications, the type of materials used is of great importance. Ensure you select materials that can withstand radiation, vibrations, and extreme temperatures. Ensure you have the proper certifications for these items.

PCB Aerospace projects often use special laminates and high-grade substrates. These materials reduce the risk of failure in harsh aerospace environments.

#3 Following Proper Design Standards

When designing an aerospace PCB assembly, it is also essential to adhere to strict design standards. It encompasses the quality of signals, routing width or density, heat conduction, and other factors. Let’s go through each one by one.

Signal Integrity

In space, accuracy is everything. A single mistake can lead to a significant problem. You must ensure that there is as little noise, delays, and signal distortion as possible. In this case, a reliable PCB manufacturer always provides access to advanced tools. This way, you can optimize signal paths and avoid crosstalk.

Heat Conduction

The space has no air, so there is no natural conduction of heat. You must find other methods for heat dissipation. In this case, you can use thermal vias, heat sinks, and other special techniques.

Vibration and Shock Resistance

Spacecraft and aircraft often experience vibrations and shocks. Turbulence is a common occurrence in the sky. To endure such circumstances, you must ensure the aerospace PCB assembly is ready for it.

You can opt for secure mounting methods and robust board designs. These methods help prevent component damage.

EMI Shielding

EMI stands for Electromagnetic interference. It is typically an unwanted energy made from an electronic signal. It may disrupt the performance of a printed circuit board (PCB).

EMI shielding is crucial in aircraft and is often called a serial killer. EMI failed most badly in the crashes of TWA Flight 800 in 1996 and Swissair Flight 111 in 1998. Additionally, it caused a PCB to fail, resulting in the crash of EgyptAir Flight 990 in 1999.

EMI shielding is part of aerospace PCB services. Copper casings and coatings are used for this. Electromagnetic compatibility is enhanced by utilizing the appropriate protection.

Routing Guidelines

The above few factors greatly affect the PCB routing. The space has no atmosphere, meaning the heat is trapped there. If you want to dissipate it, you must ensure that other techniques are used. A proper routing can help you in that case.

Besides, cosmic rays and radiation create random electrical noise. In this case, shorter traces, differential pairs, and guard rings powerfully help.

Extreme temperature swings and microgravity also affect the function of the PCB. Thermal relief pad and copper pours greatly help here.

#4 Component Placement

Component placement also affects PCB performance. Aerospace PCB assembly is no exception. It must adhere to strict guidelines for component alignment and spacing.

Note that a professional component placement always ensures low noise. It also improves cooling and prolongs durability.

#5 Use Heavy Copper Technology

Every aircraft system requires highly reliable solutions. In this case, high copper technology plays a crucial role.

High-copper technology is typically designed to handle high currents and dissipate heat effectively. The primary function of this technology is to strengthen and enhance the circuit’s durability. This is usually helpful in extreme conditions.

#6 Use of Flex and Rigid-Flex PCBs

Both flexible, rigid-flex, and rigid printed circuit boards (PCBs) are widely used in the aerospace industry. They have different uses and applications. The flex and rigid flex, though, are the most common.

Flexible ones are lightweight and save a lot of space, which is very necessary for aircraft components. Rigid-flex PCBs, on the other hand, add strength and flexibility.

Both flexible and rigid-flex PCBs connect complex systems. Typical uses include satellites, avionics, control systems, and communication devices.

#7 Use Conformal Coating

Conformal coating is a specialized type of layer applied to circuit boards. It mainly protects your boards from moisture, dust, and chemicals. This coating also prevents corrosion and short circuits.

As you know, most aircraft and spacecraft often go through extreme conditions. Additionally, high heat, pressure, or vibration may damage the circuit board, particularly in component placements. To resolve this problem, you can opt for conformal coating on the PCBs.

#8 Rigorous Testing for Aerospace PCB Assembly

Every aerospace PCB assembly undergoes rigorous testing. This includes functional tests, thermal cycling, vibration tests, and more. Testing ensures performance, safety, and reliability.

Looking for an Aerospace PCB Assembly Manufacturer?

Contact us Today if you are looking for an aerospace PCB assembly manufacturer. UETPCB is a leading manufacturer of high-quality PCBs for automotive, aerospace, military, and more. We have a very professional team of experts who are always happy to assist you.