With the rapid development of the electronic industry, the size of electronic products is getting smaller and smaller, and the power density is getting larger and larger. To solve the problem of heat dissipation is a great challenge to the design of the electronic industry, and aluminum PCB is undoubtedly a good way to solve the problem. Compared with the traditional FR4 printed circuit board, aluminum PCB can reduce the thermal resistance to the minimum. Aluminum PCB has excellent heat transfer performance compared with ceramic circuit boards, and its mechanical properties are excellent.

Common FR-4 PCB has poor heat dissipation, ceramic PCB is relatively stable, not easy to deformation in high temperature and humidity environment, but the price is expensive, commonly used in high-end products. If your product is not so high-end, such as a large area of high-power LED board, but need very good heat dissipation performance, then the most economical for high performance and low-cost material is aluminum PCB.

What is Aluminum PCB?

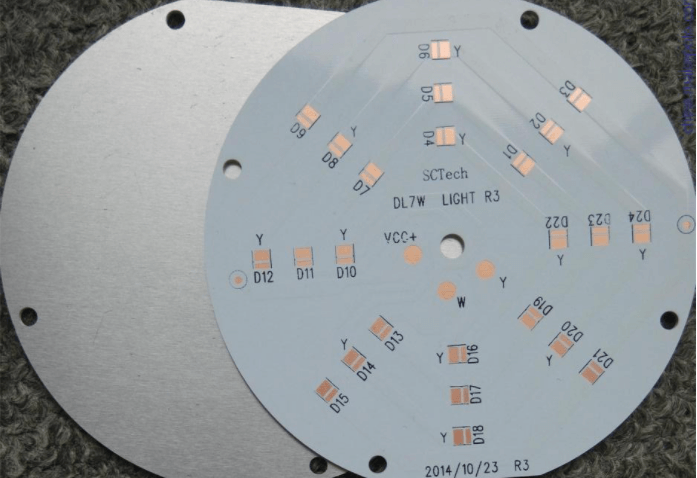

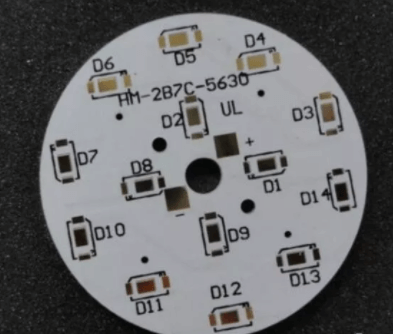

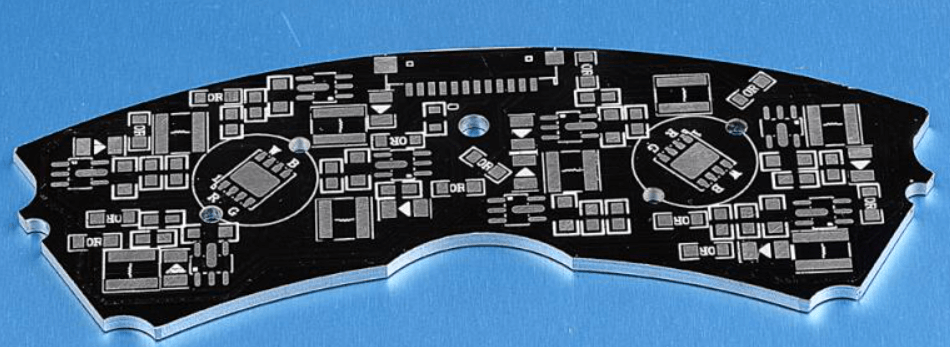

Aluminum substrate is a kind of metal base copper PCB with good heat dissipation function. Generally, a single side aluminum PCB is composed of three layers of structure: circuit layer (copper layer), the thermal insulation layer and the metal base layer. Used in high-end products normally designed as double side aluminum PCB, structure for the circuit layer, insulation layer, aluminum base, insulation layer, circuit layer. Very few applications used for multilayer board, as the cost price is rather stiff.

The structures of Aluminum PCB

1.Circuit Layer

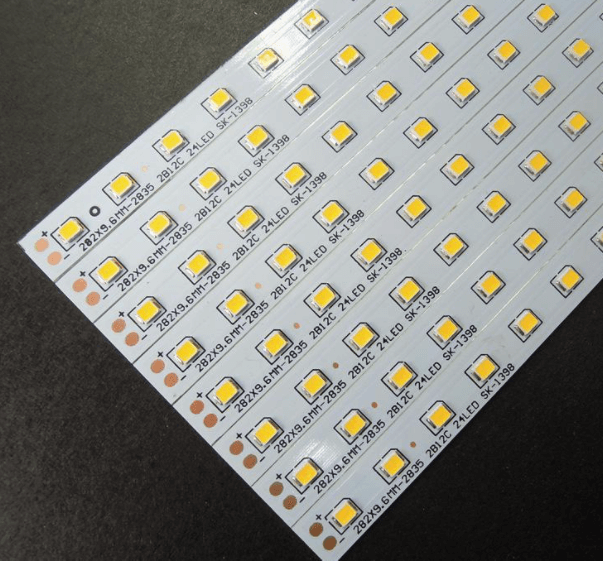

The circuit layer (electrolytic copper foil) of the aluminum PCB is etched to form a printed circuit for the assembly and connection of the device. Compared to conventional FR-4, the aluminum substrate can carry higher current with the same thickness and the same track width.

2.Thermal Insulation Layer

Thermal insulation layer is the core technology of aluminum PCB, which mainly plays the functions of bonding, insulation and heat conduction. The insulation layer of aluminum PCB is the largest thermal conductivity barrier in power module structure. The better the heat conduction performance of the insulation layer is, the more conducive to the diffusion of heat generated during the operation of the device, and the more conducive to reducing the operating temperature of the device, so as to improve the power load of the module, reduce the volume, prolong the life, improve the power output and other purposes.

3.Metal Base Layer

The metal base layer is made up of an aluminum alloy substrate. What kind of metal do use as an insulating metal substrate. This depends on a combination of the coefficient of thermal expansion, thermal conductivity, strength, hardness, weight, surface condition, and cost of the metal substrate.

The performance of Aluminum PCB

1.Thermal Dissipation

At present, a lot of double side Aluminum PCB, multilayer Aluminum PCB with high density, large power and difficulty in heat dissipation. Conventional FR4 and CEM3 PCB are poor conductors of heat, which are insulated between layers and cannot heat dissipation, leading to high temperature failure of electronic components, and aluminum PCB can solve the problem of heat dissipation.

2.Thermal Expansion

Thermal expansion and cold contraction are the common nature of substances, and the coefficient of thermal expansion of different substances is different. Aluminum based printed board can effectively solve the problem of heat dissipation, thus alleviating the problem of heat expansion and cold contraction of the components on the printed circuit board, and improving the durability and reliability of the whole machine and electronic equipment, especially to solve SMT (surface mount technology) thermal expansion and cold contraction problem.

3. Dimensional Stability

The size of aluminum base PCB is obviously much more stable than that of insulated printed boards. Aluminum based printed circuit boards are heated from 30℃ to 140~150℃ with size variation of 2.5~3.0%.

4.Other Performance

Aluminum PCB has other good performances, such as have shielding effect; Replace the ceramic substrate and component of radiator; improve product heat resistance and physical properties; Reduce production costs and labor.

The advantages of Aluminum PCB

1) The heat dissipation is significantly better than that of standard FR-4 PCB.

2) Comply with RoHS requirements, more suitable for SMT process

3)Reduce radiator and other hardware assembly cost, reduce product volume; Optimal combination of power circuit and control circuit

4) Heat conduction is more efficient than traditional rigid PCB

5) Thermal conductivity is 5 to 10 times compared with FR4 PCB

6) A lower copper weight can use than IPC recommended

The applications of Aluminum PCB

Aluminum PCB is widely used in general audio equipment, power equipment, communication electronic equipment, office automation equipment, automobile, computer, power module, Lighting and medical equipment, etc.

1.Audio Devices: input and output amplifiers, balance amplifiers, audio amplifiers, preamplifiers, power amplifiers, etc.

2.Power Supply Devices: switching regulators, DC/AC converters, SW regulator, etc.

3.Telecommunication Devices: high-frequency amplifiers, filtering appliances and transmitter circuit.

4.Automotive Devices: electronic regulators, lighting and power controllers, etc.

5.Computer Devices: CPU boards, floppy drives and power devices

6.Office Automation Devices: electric motors and drives

7.Power Module Devices: converters, solid-state relays, power rectifiers, and bridges

8.Lighting Devices: Street lighting, Traffic control lighting, Interior building lights, Landscape lighting, and Camping gear. With the promotion of energy-saving lamps, all kinds of energy-saving LED lamps are welcomed by the market, therefore, aluminum PCB for LED lamp has been widely used.

9.Medical Devices: Operating room lighting, Surgical lighting tools, High power scanning technology, and Power converters.

10.LED display: LED display; Display with LED light source

Three major differences between FR4 and aluminum PCB

1、Price

FR4 PCB board will be much cheaper than aluminum PCB.

2、Technology

FR4 PCB can be divided into double-sided copper foil FR4 board, perforated copper foil FR4 board and single-sided copper foil FR4 board according to different materials and production techniques. Of course, FR4 PCB made of different materials will be different in price.

3、Performance

Because of the good thermal conductivity of aluminum PCB, so the heat dissipation performance of aluminum PCB is much better than that FR4 PCB.