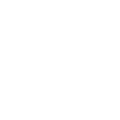

Automotive PCBs are a high-tech product used in the field of automobile manufacturing. These boards are used to control the various systems of the car, including the engine, brakes, electricity, audio, and more.

Automotive circuit boards must be highly reliable. Because they work in extreme environments such as high temperature, shock and humidity. Due to the special needs of automotive circuit boards, they need to be designed and manufactured to a high standard. Special materials and processes that meet automotive industry standards are required. The manufacture of automotive circuit boards requires a high degree of specialized skill and experience.

Applications of Automobile PCBs

Engine Control Unit (ECU):

Automobile PCBs are used in the ECU, which is responsible for controlling the engine’s performance, fuel injection, ignition timing, and other functions.

Anti-lock Braking System (ABS):

Automobile PCBs are used in ABS to ensure that the vehicle’s wheels do not lock up during braking, resulting in better control and safety.

Infotainment Systems:

Automobile PCBs are used in the infotainment systems of modern cars, such as the radio, GPS, and other entertainment functions.

Climate Control System:

Automobile PCBs are used in the climate control system to regulate the temperature and fan speed of the car’s cabin.

Lighting Systems:

Automobile PCBs are used in the lighting systems of the car, including headlights, brake lights, turn signals, and other lights.

Power Distribution:

Automobile PCBs are used in power distribution systems to distribute power to various parts of the vehicle.

Types of Automotive PCBs

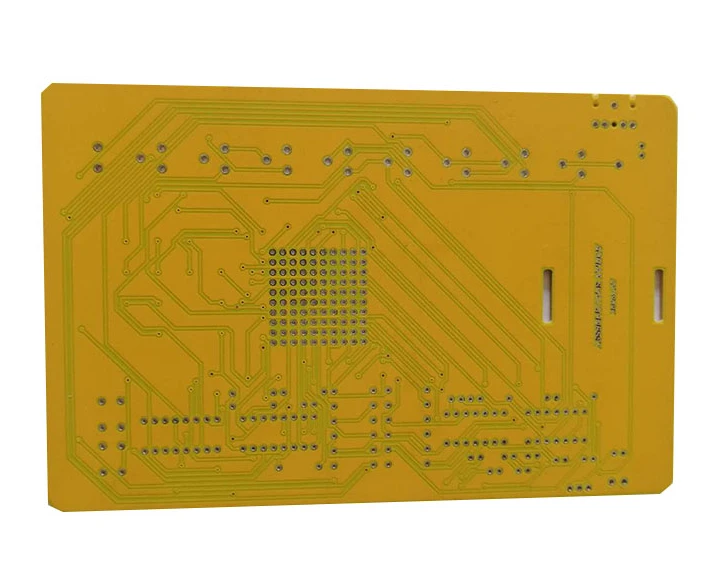

Single layer PCBs:

Single-layer PCBs are the simplest and most basic type of PCBs used in the automotive industry. They are used for low-cost applications that do not require complex circuitry.

Double-layer PCBs:

Double-layer PCBs are more complex than single-layer PCBs and are used in applications requiring a higher density of components.

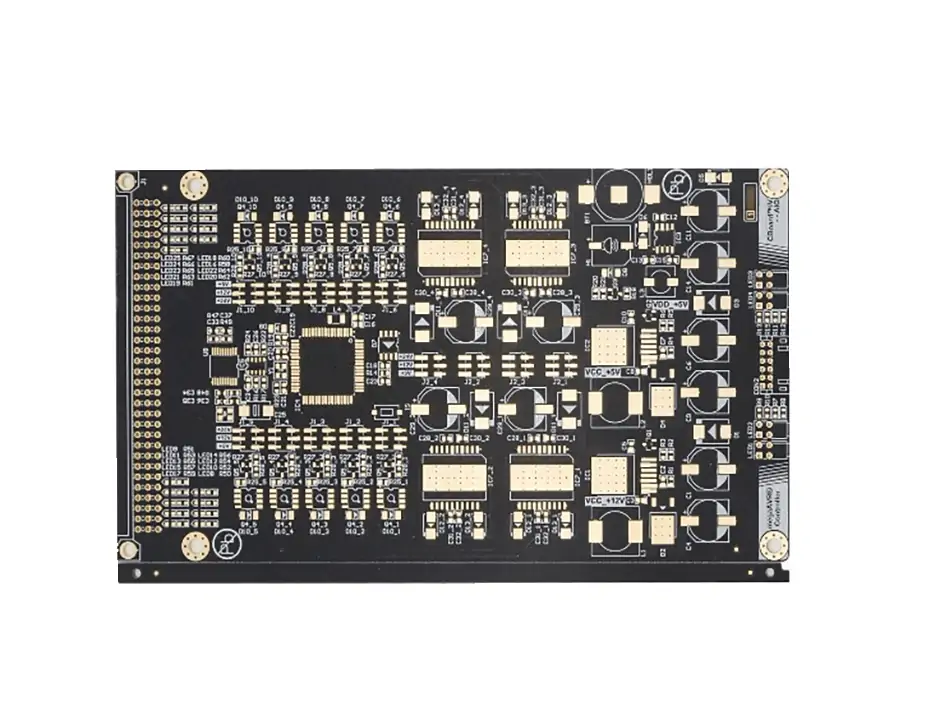

Multi-layer PCBs:

Multi-layer PCBs have several layers of conductive material sandwiched between insulating layers. They are used in applications that require high-density, complex circuitry, and good electromagnetic compatibility (EMC) performance.

Flexible PCBs:

Flexible PCBs are made of flexible materials and are used in the automotive industry for applications that require a high degree of flexibility.

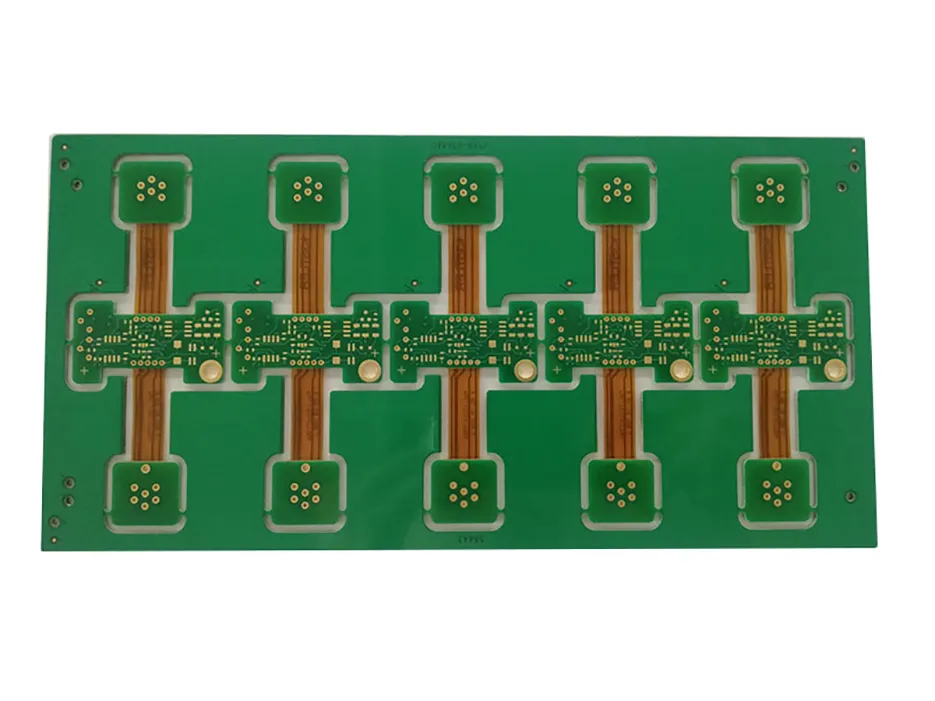

Rigid-Flex PCBs:

Rigid-Flex PCBs are a combination of rigid and flexible PCBs and are used in applications that require both flexibility and rigidity.

High-Temperature PCBs:

High-temperature PCBs are designed to withstand high temperatures, making them suitable for use in automotive applications that operate at high temperatures, such as the engine control unit (ECU).

Automotive PCB standards

| standard encdoing | standard name | Publisher | required content |

|---|---|---|---|

| IPC-6012D | Qualification and Performance Specification for Rigid Printed Boards | IPC | Quality and Performance Specifications for Rigid Circuit Boards |

| IPC-6013C | Qualification and Performance Specification for Flexible Printed Boards | IPC | Quality and Performance Specifications for Flexible Circuit Boards |

| IPC-6018B | Qualification and Performance Specification for High Frequency (Microwave) Printed Boards | IPC | Quality and Performance Specifications for High Frequency (Microwave) Circuit Boards |

| IPC-2221B | Generic Standard on Printed Board Design | IPC | Common standards for circuit board design |

| IPC-4101C | Specification for Base Materials for Rigid and Multilayer Printed Boards | IPC | Specifications for Rigid and Multilayer Circuit Board Substrates |

| AEC-Q100 | Failure Mechanism Based Stress Test Qualification for Integrated Circuits | Automotive Electronics Council | Stress testing and quality specification for integrated circuits |

| ISO 26262 | Road Vehicles – Functional Safety | International Organization for Standardization | Functional safety regulations for road vehicles |

Among these standards, IPC is an international electronics industry federation whose standards are widely used in the electronics manufacturing industry. The AEC is the Automotive Electronics Committee, and its standards are mainly for the automotive electronics industry. ISO is the International Organization for Standardization, and the standards it publishes are widely used in various fields.

It should be noted that different car manufacturers may have their own standards and requirements for automotive circuit boards, so specific requirements may vary.

Why Choose UETPCB For Your Automotive PCB

High-quality Manufacturing

We provide high-quality manufacturing and assembly services, ensuring that every Automotive PCB delivered to the customer has excellent performance and reliability.

Rich Experience

Efficient Delivery Capability

We can provide efficient delivery capability, ensuring that customers get the required Automotive PCBs within a fast production cycle and supporting customer production plans.

Reasonable Prices

UETPCB can offer high-quality Automotive PCBs at a reasonable price, providing cost-effectiveness for customer production and increasing customer competitiveness.

Flexible Production Capability