PCB technology and its products are crucial to the world today. It is critical to make the world a better place for future generations. Its products constantly improve the auto, medical, IoT, and other industries. You may have already realized the size of this market. Many makers here have very low prices and a wide range of product quality. In this case, ensuring low-cost PCB Fabrication is very important for your business.

In general, methods that save money are those that involve large quantities. It gets challenging to lower the cost of small-batch production. It’s not impossible, though. We can lower the price of even small orders if we follow our plan and work in the right way.

This article talks about how to make low-cost PCB fabrication. To keep this cost as low as possible, you and the PCB maker need to think about a few things.

PCB Fabrication Low-Cost Tips for Small-Batch Orders

Low-cost PCB fabrication can be achieved by implementing a few key measures. You must optimize the whole package for it. This section provides cost-saving tips for small-batch PCB orders. At UETPCB, you are always welcome to negotiate the quality and plans for your orders.

Tip #1: Stick to Standard Specifications

Adhering to standard specifications is the most effective way to ensure low-cost PCB fabrication. Custom PCB costs are higher due to unique forms, materials, and designs. For custom lengths and widths, manufacturers typically need special tools. This may incur an extra charge for the production process. Therefore, we always recommend that our customers refrain from unnecessary customization. In this case, you will have to consider the following three factors.

A. Prioritize Standard Circuit Board Shapes

Choosing the correct board shape can help you achieve the lowest cost. For example, rectangular or square-shaped boards are cheaper to produce. On the other hand, if you choose an odd shape, it may incur an extra cost. Therefore, manufacturers prefer regular shapes over irregular ones to minimize setup time.

Additionally, simple forms offer compatibility with automated assembly. Therefore, select the appropriate shape for your process.

B. Keep Layer Counts Within Common Ranges

PCB board costs also depend on the number of layers. You should select a typical range of layer counts for low-cost PCB manufacturing. Two-layer and four-layer boards are the most affordable. More layers will increase your manufacturing and material expenses. You should add extra layers only when necessary.

Using fewer layers will ensure quick delivery. Hence, choosing simple layer counts will make PCB manufacturing affordable.

C. Use Standard Trace Widths and Spacing

Low-cost PCB boards require standard trace widths and spacing. For this reason, most manufacturers standardize 6-mil traces and spacing. As you know, smaller traces require more advanced processes, which adds cost. Therefore, wider traces reduce the manufacturing cost and defects.

Tip #2: Optimize PCB Layout for Cost Efficiency

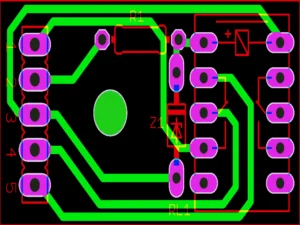

Next, you can consider optimizing the PCB layout. In this case, you can reduce the board’s overall size, spacing, hole diameter, and vias.

A. Reduce Board Layout Size Without Sacrificing Functionality

PCB cost can be compromised while keeping its functionality. You can create small boards. Small boards use fewer materials, which saves money. Here, you need a compact design that also reduces waste. Moreover, space could be saved with more negligible traces and vias. You have to avoid empty areas to maximize their use. Recheck the layout to keep all functions intact.

A well-optimized design can keep the PCB small and cost-effective without losing performance.

B. Maintain Minimum Spacing Requirements

It’s another way to ensure you get an effective PCB at an affordable cost. As you are aware, proper spacing can help prevent electrical and short-circuit issues. That’s why PCB makers suggest a certain amount of space between them. Additionally, maintaining sufficient space between signal traces ensures they remain intact.

These steps will also help you decrease errors and increase durability. If you follow these regulations, making PCBs will be easier, cheaper, and more useful.

C. Optimize Hole Diameters and Via Selection

Low-cost PCB manufacturing needs optimized hole Diameters and Via Selection. You must use a standard hole size to avoid the extra charge. Most manufacturers support standard drill sizes ranging from 0.3 mm to 0.5 mm. Special drills are needed for small holes. It increases the costs as well. Therefore, microvias should be avoided unless required for high-density design.

Keep your via count low to simplify your manufacturing. If you follow standard hole and via sizes, it will expedite production and reduce your costs.

D. Limit Layer Count Where Possible

As mentioned earlier, two- or four-layer options are standard and affordable. The more layers you increase, the more it will get costlier. For a simple circuit, fewer layers are best for the work. On the other hand, high layers need advanced fabrication and higher costs. So, it will be helpful to you to use standard numbers of layers.

Another advantage is that it also improves production speed. Therefore, keep your layer count to reap these benefits.

E. Design with Penalization in Mind

Penalization refers to the process of assembling multiple boards into a larger panel. In this case, you must maintain proper spacing to ensure easy separation. Avoid complex forms to fit more boards per panel—easy penalization saves time and money. A well-planned layout maximizes material use.

Lastly, make the design simple with penalization and ensure an efficient manufacturing process.

Tip #3: Skip Unnecessary Finishes and Exotic Materials

Another critical way to achieve low-cost PCB fabrication is to skip unnecessary finishes. There are various methods of PCB finishing, and selecting the correct one is a wise skill for reducing PCB costs. HASL or Hot Air Solder Levelling is much cheaper and more effective. On the other hand, ENIG and gold finishing are more expensive. However, ENIG can ensure you have longer-lasting service lives. PCB factories can utilize advanced machinery to achieve high-speed finishing.

You can also use standard copper thickness, such as 1 oz, for low-cost exotic materials. To save money, consider using regular green solder masks. Colorful printing costs more without improving productivity. Choosing these materials will ensure you have a high-quality product at a lower price.

Tip #4: Leverage Longer Lead Times for Better Pricing

Fast processing and instant sales also increase costs. Therefore, makers should follow a consistent lead time to process orders efficiently. At this point, you have to take a few steps to improve pricing. Low pricing is achieved through non-urgent work, long lead periods, and avoiding last-minute changes. Moreover, extra time allows you to review the plan more carefully and reduce mistakes.

Tip #5: Choose Cost-Effective Materials Without Compromising Quality

Considering cost efficiency, you must choose the right material without sacrificing quality. In this case, FR4 is a cheaper and widely used material. It will give you a balance between cost and performance. You may use Rogers for high-frequency applications, but it is expensive. Instead, choose a typical copper thickness of 1 ounce for efficiency in most designs.

You can also use polyimide or ceramic for specific applications. These materials are suitable for heat-resistant or flexible applications. Green solder masks are the most common and popular masks for PCBs. Additionally, you may find it more cost-effective with balanced performance. However, your choice may depend on your specific project needs.

Tip #6: Select the Right Manufacturer for Small-Batch Production

A few manufacturers specialize in small orders and offer better pricing. UETPCB is one of the best. Some factories may have minimum order requirements. Compared to them, UETPCB suppliers help customers find the best deal.

For selection, look for a review of each manufacturing company. Discover small-batch orders, shipping, product quality, price segments, and more. With this information, you should be able to find the best company for your needs.

Tip #7: Ensure Your Design and Gerber Files Are Error-Free

The PCB board cost also depends highly on your design. Therefore, select a compact design and ensure the Gerber files are error-free. To accomplish this, Gerber readers and DRC tools should be used to check design files.

To avoid connectivity problems, ensure perfect layer alignment. If a board has mask or silkscreen defects, it can easily malfunction. It may incur extra costs. Review your design specifications before submitting. Indeed, these steps will help you achieve low-cost PCB boards for small-batch orders.

Summary

Let’s wrap everything up! Not every manufacturer can offer you a reasonable price with small batch production. A very flexible factory, such as UETPCB, is more adaptable in this case. In this article, you have learned how to create low-cost PCB fabrication. You have considered various critical factors that heavily influence the PCB cost.

First, stick to your standard specifications. Always opt for the widely available specs. Custom sizes add lead times and manufacturing costs. Next, optimize your PCB layout. Consider the board size, hole diameters, vias, and spacings in this case. Then, opt for the most reliable and cost-effective surface finishing.

With lasers, you can decide between PCB materials for more cost-efficiency. And finally, and most importantly, choose the proper manufacturer that offers small-batch production. If you have any questions, please don’t hesitate to contact us.