In the twentieth century, robotics became a critical part of our everyday lives. We see it in homes, factories, hospitals, and even in restaurants. From robot vacuum cleaners to robotic arms in factories, they make our lives faster and more productive. Therefore, a custom PCB robot is a critical topic to discuss.

Custom PCBs for robotics can differ from the regular electronics we use. It needs AI integration, processing chips, sensors, and multiple functions. It is essentially a minicomputer with the capability to make self-decisions. Creating such PCBs could be a challenging task. Thus, more and more PCB manufacturers are investing in robotics for their PCB manufacturing processes.

This article focuses on custom PCBs for the robotics industry. You will learn about various kinds of robotics projects that you might be interested in. Additionally, you will learn more about how to build your first PCB robot.

Starting a Robotics Project

Robotics has brought a new revolution to the current world. Besides, people are working with robotics to shape the next world. It boosts our efficiency in both real life and industrial life. The next world will be designed with innovative robots to make life possible. In today’s world, robots are ubiquitous in modern and digitalized countries.

You may think of robot vacuum cleaners, autonomous vehicles, and marine equipment. If you want to create a project for industrial applications, you could try robotic hands. Today, in 2025, AI integration has become popular. You can try adding AI to your robot to experiment and see if it can do something more.

The robotic market is growing quite rapidly. The market is expected to increase by approximately $14 billion in 2025. It is expected to reach over $50 billion in revenue by 2030, with a substantial annual growth rate of 29%. If we consider service robots, they are expected to surpass $63 billion in 2025. Humanoid robots are also growing faster, from around $2.9 billion in 2025 to $15 billion by 2030. Overall, robotics will be the solution to many problems in the future world.

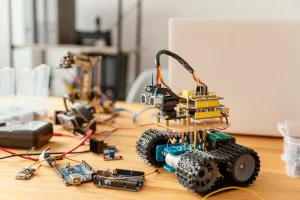

Personal Project

When thinking of personal projects, you can come up with various project ideas. You may start with Arduino robots. Obstacle robots could be a great start. It typically utilizes multiple sensors to detect obstacles in front and make decisions. It is a switch case programming language. This type of robot is widely used in autonomous vehicle projects.

You can also think about IoT-based robots. IoT, or Internet of Things, is a relatively modern technology. It offers you better controllability and connectivity. Industrial machinery and robotic arms are excellent examples of this project.

Whatever personal project you may have in mind, you cannot do it without PCBs. PCBs are the backbone of these robots. It includes everything the robot needs to decide, such as sensors, motors, and controllers to run the system smoothly. Overall, they control everything from charging to movements.

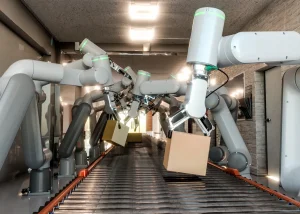

Business Project

In business, productivity, speed, and quality are crucial. Manual intervention could be slower. For example, we will manually inspect defective products, assess their quality, and perform packaging. What if you set up a robot that detects defective products and decides based on that information? They can also check the quality and perform exact packaging. This way, you can make your business run much faster and more efficiently.

Therefore, robotics in business sectors plays a significant role. Automation is a solution to the complex work in business sectors. It saves both time and money with high-precision results.

In hospitals, hotels, and offices, people use delivery robots. They carry items safely and quickly.

Robots are used in factories and power plants. They check machines and reduce risks in field operations.

Custom PCB for Robotics: The Brain Behind Your Robot

When creating robots, standard PCBs are not enough. You must customize it, adding the necessary components to meet specific requirements.

Specific Design for Specific Task

When creating robots and robotic tools, custom design is crucial. Each robot is made for a unique purpose. For this reason, robotics PCB design must be flexible according to the needs. For example, robot vacuum cleaners require a compact design and advanced navigation capabilities. On the other hand, robotic arm factories need strength and precision for better operational work.

Delivery robots, on the other hand, must be aware of dynamic worlds. Inspection robots must utilize intelligent detection sensors.

Each type of sensor and processing chip used on the PCB needs special routing facilities. Sensor reading may be wrong due to EMI or the EMS effect in the PCB. To avoid such problems, a proper PCB and routing design is necessary.

Integration of Multiple Functions

Nowadays, robots are not limited to one functionality. It often uses more than one function. This may make the design complex, but also make it powerful for versatile work.

A robot laser cleaner is not just capable of cleaning; it can also detect rust, dirt, or paint layers via sensors. In this system, the PCB connects the sensor with the cleaning laser. When it finds any dirt, the laser beam approaches to clean it off. This enables the robots to act intelligently and complete their tasks with precision.

Another example of this is an autonomous driving robot. Their PCB includes a gyroscope to balance. It can also measure distance using lidar. Additionally, with camera integration, the robot’s vision is enhanced. Odometry sensors track movement. All these features must work in sync. The PCB ensures smooth communication between them.

Robot hands used in industries can perform various tasks simultaneously. They detect objects by various sensors and decide on the next step. They have mobility in their grip, pressure perception, and dexterity in their movement. All these integrations make the robot hand much more reliable and flexible.

Improved Signal Integrity and Performance

Signal integrity is also crucial in robotics. Robots operate in a dynamic world filled with a wide variety of objects. When sending signals to detect objects, it sends various types of responses. It becomes challenging to detect objects of unknown. Therefore, intelligent filtering and detection are necessary.

You must be concerned about reducing noise and interference in the signal. Otherwise, it may result in a poor signal and eventually fail to detect the object successfully. This way, a robot might lose accuracy and slow down its working speed.

To address these issues, follow strict guidelines when designing the PCBs. A good PCB design will reduce errors and risks of hampering working ability. Ensure there is strong signal integrity, which provides better performance. Without it, robots cannot handle complex or high-speed tasks well.

Optimize Power Management

Power management is a critical issue, especially when deploying a robot into the field. They usually use batteries as a power supply. If the power runs out, you will need to locate your robot and recharge it. Therefore, power management for robots is very important.

You need to perform power optimization to ensure a longer operational time. You must optimize the entire design to minimize downtime and enhance overall efficiency. You can add energy-efficient components, sleep modes, and adaptive power allocation.

Durability in Harsh or Mobile Environments

The durability of the PCB is crucial, especially for mobile robots. These robots often operate in harsh environments, experiencing vibrations, shocks, and extreme heat. You must be aware of these situations when you are designing the PCB. This way, you can keep the PCB secure and safe from damage or errors.

How to Build Your First PCB Robot

Building your first PCB robot is an exciting endeavor. You will explore the world of automation and artificial intelligence. However, dealing with custom PCBs can be a challenging task for you. Also, selecting a reputable PCB manufacturer is crucial. The following steps outline the general guidelines for building your first PCB robot.

Step #1: Define Your Robot’s Purpose

Start by defining the purpose of your PCB robot. What will it serve? Is it for cleaning, carrying, or avoiding obstacles? Finding the correct sensors and motors is easier with clear goals. A strong purpose helps your PCB design support the function and improve robot performance.

Step #2: Sketch a Smart and Space-Efficient PCB Layout

Make a rough layout for your PCB. Keep the size of your PCB small, but make it multifunctional. Reduce wiring by placing sensors, controllers, and other necessary equipment in proximity. Utilize a compact design to maximize space efficiency and enhance performance. It also makes the PCB robot lightweight and easy to fit into small robotic systems.

Step #3: Design for Reliable Power Distribution

As mentioned earlier, power distribution is critical in robotics. You can balance this power distribution by creating an optimized custom PCB. Place power lines carefully to avoid drips. Thus, you can achieve a stable power transfer, which might help your PCB robots run smoothly.

Step #4: Build a Durable and Error-Resistant Circuit

As mentioned earlier, robots can face harsh conditions. Therefore, design your PCBs to resist errors and utilize protective equipment, such as fuses and diodes. Ensure it accurately tracks the required strength to handle the current. It lets you prevent technical failures when working with robots.

Step #5: Maintain Clean Signals with Proper Routing

To ensure clean signals, use proper routing techniques. Proper routing can easily decrease the chances of interference from waves. Keep analog and digital lines apart from each other. Shield sensitive circuits if needed. Signal purity enhances sensor and communication accuracy.

Step #6: Select PCB Materials that Match Your Robot’s Needs

Select materials based on your requirements and applications. Use heat-resistant materials for industrial robots. For drones and mobile robots, use thin and lightweight materials. Note that specific applications need materials. Selecting the right material will enhance durability and performance. Therefore, choose them based on your specific purpose.

Step #7: Test, Debug, and Refine the Circuit

After building the PCB robot, run tests. Inspect the signals, power distributions, short circuits, or other errors. Debug all the issues step by step. Refining improves designs, and testing your PCB robot makes sure it is secure, reliable, and ready for practical use.

Step #8: Prepare for Smooth Prototyping and Production

Once your design is tested and checked, prepare for prototyping. Prototyping is the last and final step to verify the robots before production. Thereafter, choose a reliable PCB manufacturer for accurate builds. A smooth transition to production saves cost and time simultaneously.

Why Choose UETPCB for PCB Prototype and Custom Manufacturing?

Although you have created the best PCB design, it is still not enough. You will need a reliable and high-quality manufacturing facility to ensure each component is placed in the right location. From the thickness of the PCB to the conformal coating, and even the color of the PCB, everything matters.

In this case, UETPCB is one of the best PCB manufacturers in China and a globally recognized organization. It offers in-house production lines for the manufacturing and assembly of PCBs.

Custom PCB Prototype Manufacturing and Assembly

UETPCB offers quick-turn PCB prototype services that include both manufacturing and assembly. Overall, they provide a convenient and all-inclusive solution.

The company started its journey in 2005. With more than 20 years of experience, they serve in the cheap custom manufacturing of prototypes. It’s an ideal solution for a robotics project that has a tight budget and timeline.

Simply upload your Gerber files and select the right board types. Their board varieties include rigid, HDI, multilayer, rigid-flex, and many more. They typically streamline the entire process in a way that is efficient and affordable for customers.

Advanced Adaptive Manufacturing for Robotics

UETPCB’s smart, adaptive manufacturing accommodates a diverse range of PCB types. They work with high-frequency, flexible, high-Tg PCBs that are suitable for robotics. These PCBs are ideal due to their bending capabilities, which allow them to fit into tight and moving spaces. They are mainly recommended for compact designs and multipurpose robots. Their ability to adapt materials and volume makes them excellent for evolving robotics projects.

Functional Testing After Assembly

After completion of assembly, UETPCB runs thorough functional testing. Firstly, we conduct a visual inspection. Then, our team conducts flying probe testing, in-circuit testing, X-ray inspection, and AOI testing. Lastly, functional testing is held to verify overall performance.

These steps detect PCB prototype faults and improve reliability by addressing them. With UETPCB, you can enjoy the best service with innovative, reliable, and well-performing robots.

Fast and Reliable Component Sourcing

Not every manufacturer can offer you these services. With a lack of partnerships, many PCB manufacturers fail to meet the exact delivery time. For custom solutions, component sourcing is a very critical task. UETPCB, in this case, offers you better and reliable solutions. We partner with reputable PCB component manufacturers in China and worldwide.

Whether you need the PCB for autonomous vehicles or robot arms, UETPCB is capable of meeting your demands.

Summary

Let’s wrap everything up! Robotics is growing fast in both personal and business projects. From home cleaning robots to industrial automation tools, the demand for these tools is increasing. So, if you are planning to start a robotics project, you are typically on the right track. Our world is gradually depending on AI and robots. Therefore, the market for these items is in huge demand.

If you are interested in a custom PCB for robotics, you can consider choosing UETPCB. We have already discussed why you should choose this manufacturer. For more information, please don’t hesitate to contact our customer support team.