Product design and optimization are essential in every manufacturing process. They help reduce production costs, and PCB manufacturing assembly is no exception.

PCB, or printed circuit board, is indispensable in electronic gadgets. Its design and assembly mainly depend on the gadget’s requirements. For example, rigid and flexible PCBs can be used in any product you want. A rigid PCB suits simpler designs, while flexible PCBs are ideal for complex ones.

Price is also an important parameter when designing a PCB. Flexible PCBs are much more expensive than rigid PCBs. If your product can run smoothly on rigid PCBs, it’s better to choose rigid PCBs instead of flexible ones. Above all, you must check how the market will react to your product’s final price. Think about the things that make up the cost of PCB manufacturing and assembly.

Factors that Influence Prices for PCB Manufacturing and Assembly

The following describes some factors affecting PCB manufacturing and assembly. Each factor directly influences the performance of the final product. Knowing them will help you choose the best PCB factory.

#1. PCB Delivery

Delivery formalities significantly affect the cost of PCB assembly services. Here are three things you should keep in mind. (1) Some customers ask for delivery ahead of schedule. This urgent delivery forces the company’s employees to work overtime, increasing labor costs. Overall, it increases the PCB manufacturing and assembly prices.

(2) Special logistics might also influence the delivery cost. Some customers may ask for weather control or special security in shipment. Air freight and express delivery are also parts of special logistics. (3) Some customers change the production plan while their product is already in production. In these situations, the cost might also increase or decrease.

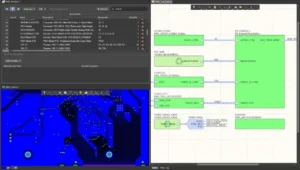

#2. PCB Design

Also, the complexity of the PCB design affects the PCB fabrication and assembly costs. The number of layers, the trace width, and component density are all very important. For example, making multilayer PCBs is complex. Also, finer trace widths or tighter spacing need precise manufacturing. The end price usually goes up when you add all these up.

#3. PCB Layout

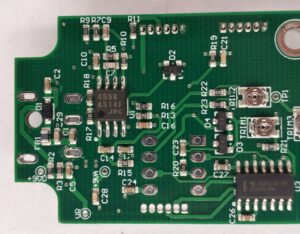

Another essential factor you must consider is the layout. A PCB generally consists of a few layers, traces, spacing, and board dimensions. In short, a PCB layout includes everything except the components.

A complex layout generally has multiple layers, finer traces, and small spacing. However, a simple layout may include only single or double-sided layers.

Complex layouts need more precise manufacturing. On the other hand, custom layouts need extra design, engineering review, and testing. But standard layouts give you cheaper options in this case.

#4. PCB Size

The size of the circuit board heavily impacts the cost of PCB production and assembly. As usual, larger PCBs need more materials and components. Although larger PCBs limit the need for smaller ones, making them is also simple. But these PCBs are ideal for bigger-sized gadgets.

On the other hand, smaller PCBs need more components in a compact size. You may even need more than one layer. Ultimately, the manufacturing process becomes complex, eventually increasing the price.

#5. PCB Material

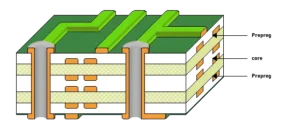

Your choice of PCB assembly and manufacturing materials strongly affects cost and performance. A PCB layout normally comprises four major layers. The first layer on top is the silkscreen layer, also known as the top silkscreen. This layer typically aids in identifying several aspects, such as components and test points.

Subsequently, the solder mask layer covers the copper traces to shield them from getting oxidized. Later, the copper layer is also known as the trace layer. Finally, the substrate layer is called the base layer, which gives your PCB structural support.

The substrate layer is typically made of fiberglass or FR4. Here, FR means fire retardant. This material is durable and perfect for high-temperature use. You may also find a cheaper option, phenolics or epoxies. But this material is not suitable for extreme conditions. The other materials used are the same for all types of PCBs.

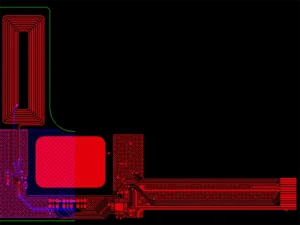

#6. PCB Trace Width and Spacing

PCB trace width refers to the conductive layer width used to make the printed circuit board. That golden, yellowish-looking layer on circuit boards is actually the PCB tracers or tracks. On the other hand, spacing in a PCB is the space between traces, pads, or holes, also known as via. These two factors are very important for determining the total performance of the PCB.

How do these two factors affect the cost of PCB manufacturing and assembly? A narrower trace width may require precision manufacturing, better equipment, and tighter tolerances.

#7. PCB Drill Hole Size

A PCB drill hole, or a via, is a small hole drilled through the PCB layers. Its main job is to connect different layers of the PCB. If it is plated with copper, it is called a PTH or Plated Through Hole. It is called an NPTH or Non-Plated Through Hole if it is not plated.

Making the narrower holes requires precision manufacturing. Besides, a special drilling process may be needed for particular types of vias. Blind vias and buried vias are noteworthy. So, you can see that making drill holes or vias affects the cost of PCB manufacturing.

#8. PCB Surface Treatment

In PCB manufacturing and assembly, PCB factories use different types of surface treatments on PCBs. HASL, ENIG, and OSP are the most frequently used ones.

HASL is cheaper, but it is not suitable for fine-pitch PCB parts and multilayer PCBs. You might want to use ENIG or electroless nickel immersion Gold for better quality. However, ENIG is much more costly than HASL. You may also consider OSP, which is of equal cost to the other methods mentioned previously.

#9. PCB Copper Thickness

Copper thickness on PCBs generally ranges from 1.4 to 2.8 mils (0.035 mm to 0.07 mm). This thickness typically depends on how much current passes through it. Therefore, for high-current circuit boards, the thickness must be wider. Typical examples include power amplifiers, motor controllers, power supply units, and more.

In PCB assembly services, copper thickness fairly affects the production cost. Therefore, when you design your PCB, pay attention to the ampere rating.

#10. PCB Prototyping

PCB prototyping is a part of custom manufacturing. These PCBs differ from standard-size ones, so you must make them from scratch. Typically, they are made in small quantities. Later, customers can order mass volume.

PCB prototyping significantly impacts overall PCB manufacturing and assembly costs because it involves designing, engineering review, and testing. Also, PCB prototyping takes longer than standard-size PCBs.

#11. PCB Testing

PCB testing is also an essential part of circuit board manufacturing. Every PCB manufacturer must do this before delivering the product. Some typical tests are AOI, ICT, FCT, and more. The cost may vary depending on the complexity of the PCB. How many test points are there? What testing equipment is needed?

High-quality circuit boards often need extra testing. For instance, HDI PCBs often need micro-via inspection. Custom testing or unique customer requirements may also increase the total cost.

#12. PCB Quality Control

Extra testing might be necessary in addition to the regular testing. Customers may request more certifications, such as environmental, safety, and electrical testing. For example, the PCBs used in the medical industry must have a biocompatibility certificate. The environmental certificates may include RoHS, REACH, and more.

On the other hand, the car industry may need thermal and vibration testing certificates. Different situations may be observed in the aerospace, marine, and robotics industries. These extra tests and certifications may increase the total cost of your PCB assembly.

#13. Freight Charges

Finally, freight charges also strongly affect the cost of working with a PCB fabrication manufacturer. In this case, the factory location plays a crucial role. An overseas shipment will cost more than a domestic one. International shipments include customs duties and other handling fees.

Air freight is generally costlier than sea freight, but you can get your product quickly. The fastest delivery is possible within three days. However, if you take the delivery by ship, you might have to wait 15 days to 1 month, depending on your country’s location. Sea freight is much cheaper than air freight.

Tips on How to Reduce Your PCB Manufacturing and Assembly Cost

The above section shows what factors affect the cost of PCB manufacturing and assembly. This section will teach you some expert tips to reduce these costs as much as possible. However, controlling the costs without compromising quality is a must.

Tip #1 Simplify Your Circuit Design

First, check your product’s design. Does it need a compact PCB? Can it accommodate a larger PCB? Based on your evaluation, you can simplify your circuit Design. This will help reduce the cost significantly.

Tip #2 Reduce Layer Count

One of the most effective ways to reduce PCB manufacturing and assembly costs is to reduce the number of layers. Each extra layer adds cost to the final PCB. In this case, you can seek expert help.

Tip #3 Use Standard Components

Use standard components on your PCB. For instance, resistors, capacitors, diodes, and ICs must be easy to find. Components with custom specs may increase in cost. Choosing standard components also helps with replacement and maintenance.

Tip #4 Try to Optimize PCB Size and Shape

When designing, assess the best fit of PCB in your gadget. In this case, you can cut the shape and size of the panel. A larger panel with fewer components is not an efficient solution.

Tip #5 Apply Advanced DFM Principles

DFM stands for Design for Manufacturability and is essential in PCB making. It states a few guidelines that can help you optimize your PCB design. In addition, it reduces errors and rework. Following DFM can help reduce costs in the Assembly of Printed Circuit Boards”.

Get in Touch with Us!

If you are looking for a PCB solution, please don’t hesitate to contact us. You can ask any questions at our customer service portal, and our team of experts is always happy to assist you.