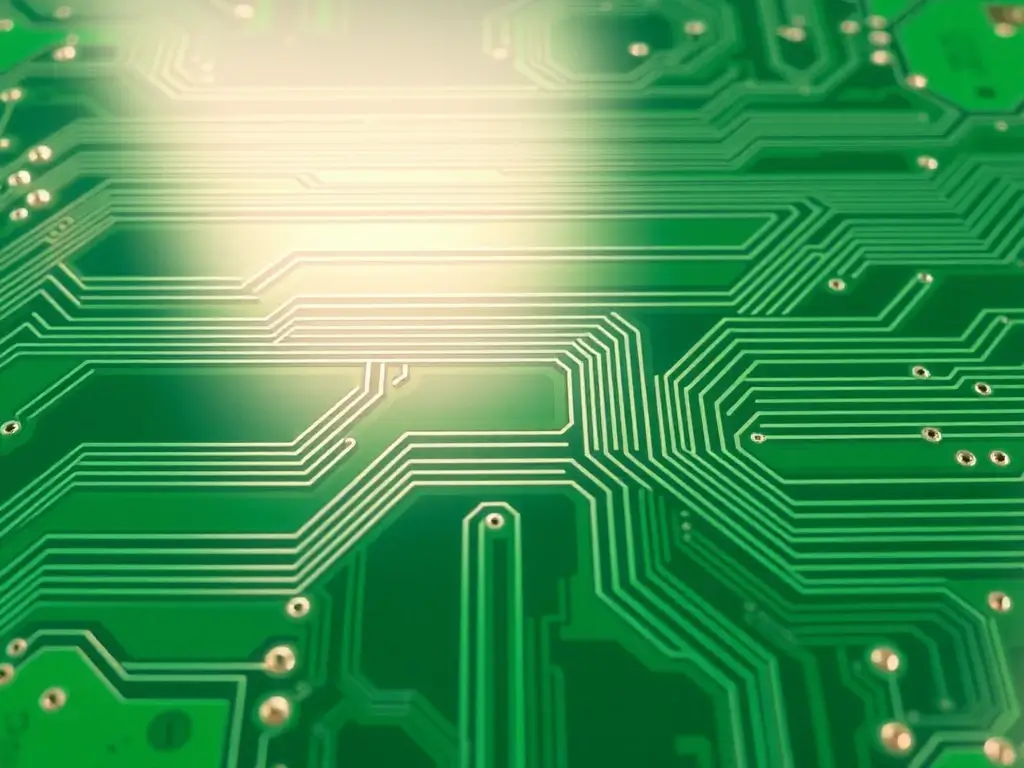

Halogen-Free PCBs Guide

Our company is committed to providing high-quality halogen-free printed circuit boards. Halogen-free PCBs lack halogen elements like bromine and chlorine. They meet strict environmental standards. These PCBs are more eco-friendly. They have great thermal stability and electrical properties. So, they suit many high-performance uses.

- Fully compliant with RoHS and REACH environmental standards

- Halogen-free content less than 900ppm

- Excellent flame retardant performance (up to UL 94 V-0 level)

- Suitable for multi-layer board manufacturing (up to 32 layers)

Halogen-Free PCBs Technical Specifications

| Category | Parameter | Specification |

|---|---|---|

| Material Properties | Halogen Content | < 900ppm (Br + Cl) |

| Tg | 150°C – 170°C | |

| Td | ≥ 330°C | |

| CTI | ≥ 600V | |

| Flammability Rating | UL 94 V-0 | |

| Board Parameters | Layer Count | 1-32 layers |

| Board Thickness | 0.4mm – 3.2mm | |

| Panel Size | Max 550 x 650mm | |

| Aspect Ratio | Up to 12:1 | |

| Design Parameters | Min Line Width/Spacing | 3/3mil |

| Min Hole Size | 0.15mm | |

| Min Via Diameter | 0.2mm | |

| BGA Pitch | Down to 0.4mm | |

| Surface Finish Options | Available Types | – ENIG |

| – HASL Lead-free | ||

| – OSP | ||

| – Immersion Tin | ||

| – Immersion Silver | ||

| – Hard Gold | ||

| Solder Mask | Colors | Green, Black, White, Blue |

| Thickness | 10-15μm | |

| Min Dam | 3mil | |

| Electrical Properties | Dk @ 1GHz | 4.0-4.6 |

| Df @ 1GHz | 0.02-0.03 | |

| Volume Resistivity | ≥ 10^8 MΩ•cm | |

| Surface Resistivity | ≥ 10^7 MΩ | |

| Quality Standards | Certifications | – IPC Class II/III |

| – UL Certified | ||

| – RoHS Compliant | ||

| – REACH Compliant | ||

| – ISO 9001:2015 | ||

| Testing Capabilities | Available Tests | – Flying Probe Test |

| – AOI Inspection | ||

| – X-ray Inspection | ||

| – Cross-section Analysis | ||

| – Thermal Stress Testing | ||

| – Ionic Contamination Testing |

Advantages of Halogen-Free PCBs

Halogen-free materials do not release toxic halides when burned.

Halogen-free PCBs have a higher decomposition temperature, and they can withstand higher temperatures without degradation.

Halogen-free materials are less likely to produce corrosive and toxic gases in the event of a fire, reducing risks to personnel and equipment.

Consumers and companies increasingly prefer environmentally friendly products, driving the demand for halogen-free PCBs.

Applications of High-TG PCB

Automotive Industry

Industrial Applications

Telecommunications

Consumer Electronics

Aerospace Applications

Medical Equipment

We’re Here To Help You

To better understand our products and services, feel free to contact our customer service team at any time. We look forward to establishing contact with you, solving your needs, and creating wonderful cooperation opportunities together!