Most of us often make mistakes when choosing the right product. Specifically, we become confused when we try to balance between cost and quality of the product. PCB manufacturing is no exception.

In the electronics industry, there are various quality levels of printed circuit boards. But which one offers the best quality over price? That’s where we often make mistakes, especially when we are beginners.

When assessing this balancing issue, the first step is to understand how PCBs are manufactured. When you know all the technical parameters, you can compare the qualities to around 80%. The remaining 20% depends on your expertise and level of technical knowledge.

Sometimes, expensive PCBs don’t mean the best quality. On the other hand, cheaper PCBs are not always of bad quality. The PCB price mainly depends on the manufacturing location, labor cost, and the technology used. However, you must carefully check the quality of cheaper products.

This article primarily discusses key considerations for balancing cost and quality in PCB manufacturing.

Overview of Electronics Market Forces, Supply, and Demand

In 2024, the global PCB assembly market was valued at over $90 billion. Experts predict that the annual rate will increase by 5% based on growth and statistical trends. The CAGR rate will be 5.8%, and the market will be worth $152.46 billion by 2033.

Asia Pacific has once led the market with a 40-45% share. It’s the fastest-growing region for PCB manufacturing and assembly. Especially, China has made the most significant contribution to this region. This country is quite popular for serving a wide range of PCBs at better pricing. They provide compatible PCBs with flexible opportunities. Besides Japan, South Korea and Taiwan make a substantial contribution to the Asia region.

Anything that runs on electricity needs circuit boards. Consequently, electronic devices are crucial for our daily lives. We use them in smartphones, laptops, electronics, medical devices, and so on. Therefore, demand will always be at the forefront; it will never decline.

Sometimes the market faces problems. It could be cost, supply delays, or geopolitical issues. Despite these challenges, the demand for PCBs remains high. Manufacturers are striving to strike a balance between cost and quality while meeting immediate supply demands. It helps you connect with the global electronics market.

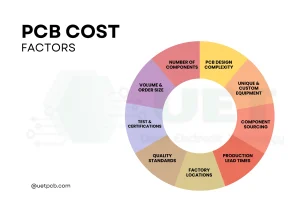

Driving Forces of PCB Manufacturing and Assembly Cost

The primary factors for PCB manufacturing and assembly are outlined below. We have categorized it into seven points and will describe each one individually.

#1 Number of Components

The number of components plays a crucial role in determining the cost of a PCB. Usually, the more components you use on a PCB, the higher the price is. Besides, assembling a dense component PCB is also complex and costly.

Therefore, keeping spaces between each component is crucial for durability. However, when you give space, the size of the PCB increases, which eventually increases the cost.

Moreover, it requires advanced testing and inspection to ensure better quality. Therefore, a PCB with fewer, more efficient components is less expensive to manufacture while still performing well.

#2 PCB Design Complexity

Using complex designs can be expensive. Additionally, handling multiple layers, tight spaces, and other complex work requires better management.

High-density layout needs time for placement and advanced testing. This will result in additional expenses. Moreover, a complex design has a significant risk of production errors. Therefore, create a simpler design that saves you time and money while maintaining proper performance that suits your job.

#3 Unique and Custom Equipment

Unique and costly equipment also drives the PCB cost. Most people prefer these items for customization. You will need special machines and tools to handle them.

Moreover, if you require non-standard shapes, designs, or equipment, you will incur additional costs. Having these issues slows down the production speed. However, customization is only cost-effective for specific performance and usage purposes.

#4 Component Sourcing

Component sourcing is a process of obtaining the necessary equipment for PCBs. It plays an essential role in PCB costing. The pricing system varies depending on the type, accessibility, and brand. In this case, it is recommended to purchase these items from a trusted supplier for optimal compatibility. This strategy may lower the cost if you source locally or buy in bulk. To get better control, take smart steps.

#5 Production Lead Times

Production lead time includes the entire production time. Rush orders or shorter production times result in extra charges. Urgent work also increases the risk of mistakes.

On the other hand, if you take the standard lead time for your production, this will minimize the cost.

Additionally, there are other benefits to choosing this option. The rest depends on your requirements. To save costs, you should choose an effective plan to proceed. This plan will assist you throughout the entire process.

#6 Factory Locations

The location of the factory is also a significant factor in this context. Here, labor capability, material availability, and rapid setups all impact costs.

Moreover, shipping rates and electricity costs can also contribute to higher charges. Factories in countries with lower wages can offer cheaper production. Therefore, consider a company based on these key factors. Choosing the correct location means balancing cost and reliability.

#7 Quality Standards

Quality is the primary determining factor. Before choosing a manufacturer, ensure that you check their quality compliance. Check the standard quality measures, such as ISO, IPC, IATF, and others. A company with these compliances can build high-quality and durable PCBs. So, don’t skip this check. Skipping it may save money, but it leads to serious drawbacks later.

How to Balance Between Cost and Quality in PCB Manufacturing

You have already gone through the factors that drive the cost of printed circuit boards. This section provides some tips to help reduce costs. We must keep in mind that we are balancing cost and quality.

#1 Break Down the Costs

Breakdown cost is a total pricing system, broken down into sections. In PCB manufacturing, it covers material selection, accessories, labor, testing, and shipping charges. It also includes PCB assembly cost.

You need to be aware of all the expenses and the current market pricing. This way, you can compare manufacturers and select the one that best suits your needs. Thus, you may have the desired product at the best price. It’s the first and most crucial step in striking a balance between cost and quality.

#2 Choose Standard Package Size

Using the standard package sizes can help you reduce extra expenses. It also enables you to avoid complexities. The most common panel sizes people prefer are 18×24, 18×12, 9×24, or 9×12.

If you want a customized solution, the manufacturer can also provide it. However, you must know that custom parts require custom tools to manufacture. Therefore, try to use standard parts and components for PCBs. Consider placing your order in mass production to achieve cost savings.

#3 Sufficient Component Spacing

Keeping standard space in PCBs can also help you maintain quality and save costs. Working in a tight space carries many complexities and is challenging to complete.

Operating in tight spaces also requires extra care and advanced machines, which can be costly. Also, there is a substantial possibility of technical errors and mistakes during manufacturing. So, it is advisable to choose a standard space for your PCB. It will make inspection and testing easier.

#4 DFA Standards

DFA refers to Design for Assembly. It focuses on the process of creating and assembling PCBs easily. This method includes standard parts selection, modular design, minimizing part variety, and other crucial steps.

With DFA, you can design the PCBs in a way that simplifies the assembly process. This approach helps you manufacture low-cost PCB assembly.

#5 Stick to the DFM Guidelines

DFM adheres to the principle of Design for Manufacturability. It’s a foolproof plan for PCB manufacturing.

If you follow the plan and stick to it, these guidelines will allow you to avoid complex features. Eventually, ensure you have proper hole sizes, drill, make traces, and perform other connection work. As a result, the process reduces delivery delays and saves time while maintaining high-quality PCBs.

#6 Consider SMDs

Surface mount devices are small, quick, and less costly to assemble than through-hole parts. This method utilizes an automated system and requires minimal space. For this reason, SMD reduces labor costs, speeds up production, and keeps up performance.

You can also balance the weight and size of PCBs using this method. Therefore, you must consider SMDs before starting production.

#7 Opt for Automated Assembly

The advantages of automated assembly are huge. This method enhances accuracy and efficiency while also reducing labor costs. Besides, automated work reduces the chance of errors, rework, and waste.

Although the initial setup may be more expensive, it will ultimately prove beneficial in the long run. That’s why the method is suitable for medium to large volumes.

#8 Employ DFT Rules

Design for Testing (DFT) is a unique method. It enables you to create PCBs in a way that makes them easy to test.

DFT involves adding test points, providing clear access to vital paths, and simplifying the design for inspection. By following DFT rules, you may control both the cost and the quality of the final product.

Get Our Best PCB Quotation Right Away!

The information mentioned above is a key tool for balancing cost and quality. If you have any further questions regarding this, please do not hesitate to contact us.

UETPCB offers fast, accurate, and affordable quotes for all your PCB needs. Please send your design files and requirements, and our team will respond promptly. So, what is holding you back? Join UETPCB to experience the best devices and services.