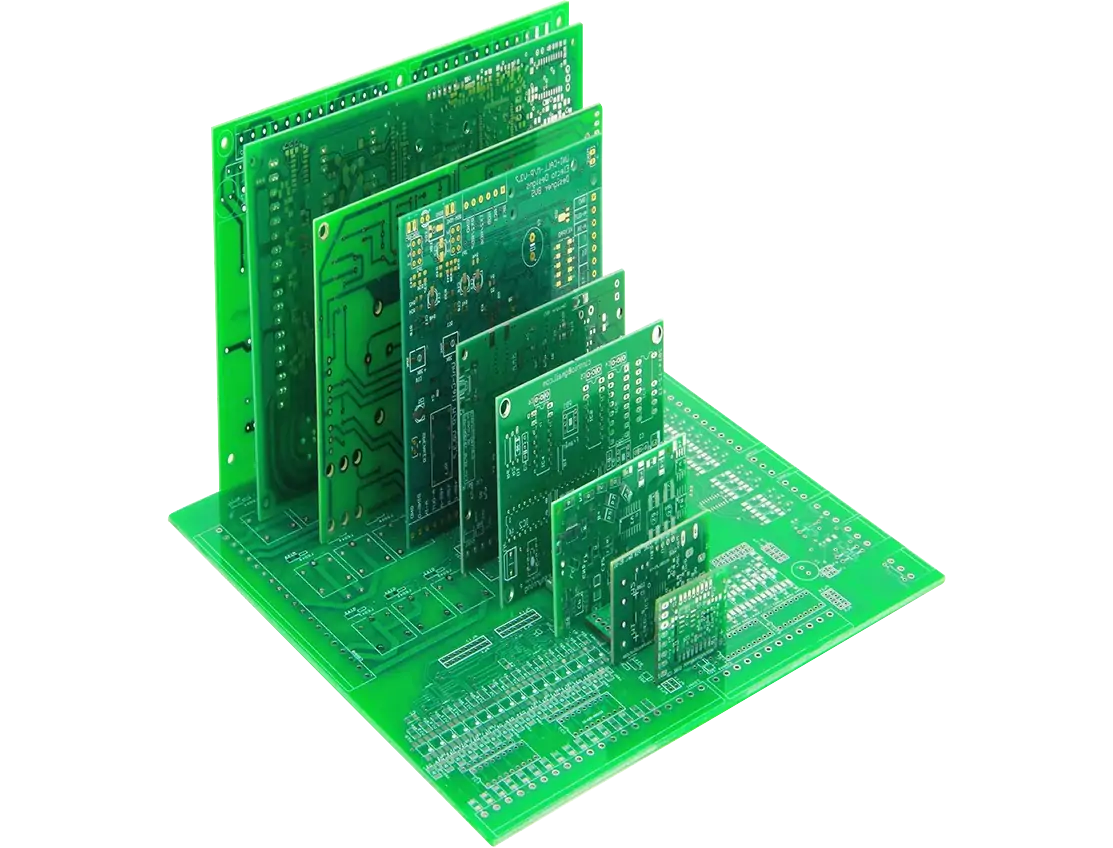

Pcb prototype service introduction

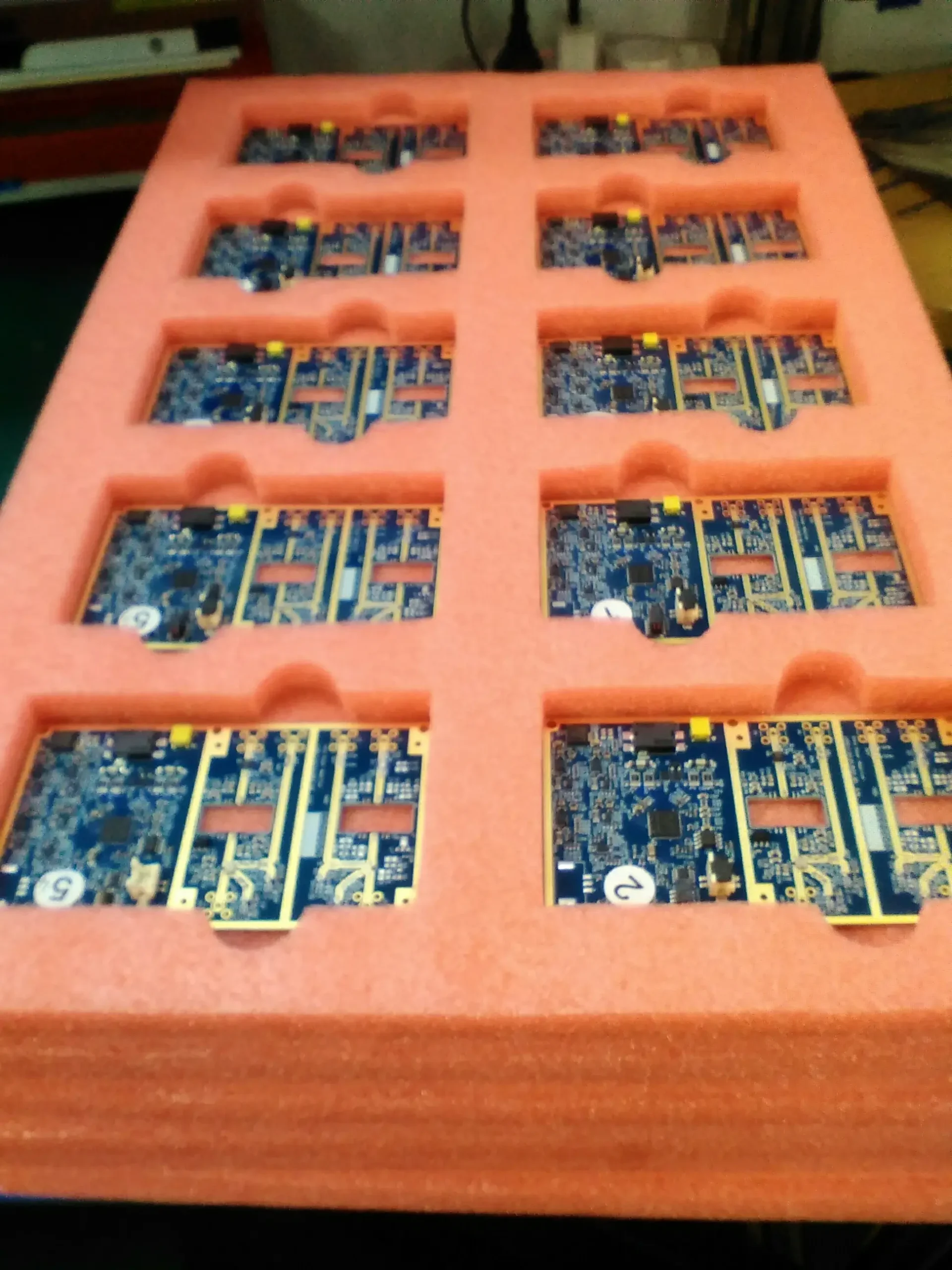

Component assembly

UETPCB is a professional pcb supplier & pcba manufacturer in Shenzhen. We focus on providing high-quality PCB assembly services. As a reliable PCB supplier, we provide one-stop service from PCB manufacturing to assembly. Our professional team has the experience and skills to meet the needs of various industries. Our goal is to be your preferred partner in China PCBA manufactory. If you need quality PCB assembly services, please contact us.

| Capability | Standard |

|---|---|

| Types of low volume PCB |

|

| DFM |

|

| DFT |

|

Prototype PCB assembly is crucial for various reasons. The primary reason is that it enables trial & error before mass production. Prototype assembly verifies product design and identifies flaws. Engineers can make necessary adjustments based on the result data and reduce potential losses. This process performs several testing and refinement of the circuit’s functionality. As a result, it ensures that the manufactured produce meets performance & quality standards.

UETPCB specializes in world-class PCB assembly services. We focus on precision and quality. As a result, our products are trusted by customers from all over the world. However, our prototype PCB Assembly services include:

DFM stands for Design for Manufacturing. This service involves a comprehensive analysis by engineers. Through this process, they ensure that the design is optimized for efficient manufacturing.

This service includes multiple solutions. These solutions include PCB proofing, prototype development, and manufacturing.

This service involves procurement of electronic components. A reliable component sourcing ensures that the prototype meets quality & specification standards.

This service provides a quick prototyping service for patches. It allows for the testing of PCB designs. Ultimately, it ensures that the part is functioning as intended.

This service involves multiple testing processes. All these services ensure the quality and functionality of the assembled PCBs.

A non-contact test method uses a robotic problem. The process checks PCB connectivity and identifies faults without test fixtures.

is an automated process to evaluate individual component functionality. It helps in detecting defects in assembled PCBs.

It is also a non-contact testing method that uses X-rays to check hidden solder joints. It also checks the internal connections and components on PCBs for quality & integrity.

The purpose of AOI is to detect defects to ensure quality assurance.

This method verifies that a product or component performs as intended. It also ensures it meets design & performance criteria.

This method involves a manual examination of the produced part. The purpose of this method is to identify visible defects.

It’s easy and convenient to start a quick proofing process at UETPCB. You can simply contact our customer support, who will guide you through the process. A quick proofing service can be simplified into the following key stages:

Any questions? Contact us anytime, and we’ll respond to your inquiries within 24 hours.

We specialize in building your pcb prototype and PCB assembly with rapid turn times.