PCB is a crucial component and is impactful in all electronic devices. Its features and quality are impressive. However, the question is always about the PCB price.

How much does a circuit board cost? This guide is for you if you want to learn about the PCB price and the various parameters determining it. We will discuss the price of a printed circuit board and factors affecting its price.

How much does a circuit board cost?

There is no definite answer to this question. The prices of printed circuits fluctuate based on type, quality, and other factors. However, they cost ten cents to ten dollars.

We have listed the major types and their costs.

| PCB Type | Quantity | Estimated Unit Cost |

| Simple 2-layer prototype (China) | 5 pcs | $0.10–$5 total |

| Basic 2-layer hobby PCB (USA) | 10 pcs | $2–$5 each |

| 4-layer standard board | 10–50 pcs | $10–$20 each |

| 6–8-layer HDI board | Low volume | $50–$100+ each |

| Aerospace-grade custom PCB | Low volume | $100–$500+ each |

Crucial Factors affecting the PCB circuit boards pricing

The price of a PCB board depends more on several factors. These can also include the shipping charges, depending on where and how many units you import.

Let’s check out the main factors here.

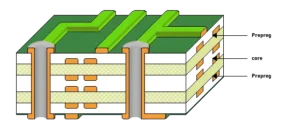

Number of layers

The number of layers is the main factor behind the elevated or reduced prices. More layers mean higher accuracy is required at a higher price. Here is the overview of the number of layers.

- 1–2 layers: Simple and cheap to manufacture.

- 4–6 layers: More complex, requiring multiple lamination cycles.

- 8+ layers or HDI boards: Require microvia drilling and advanced alignment. So prices jump here.

Usually, an increase in one layer can increase prices by more than 30%.

Board Size and Shape

What is the shape of your PCB circuit? If it is a regular or standard shape, prices differ from those of customized, peculiar, and curvy shapes. It is because the curvy shapes require a refined cutting and effective apprehension.

Moreover, size can elevate prices as well. Larger-PCB circuits require more raw materials and are time-consuming to manufacture. Therefore, their price tags are higher than those of smaller circuits.

Quantity

If you build one circuit, it is more expensive than hundreds of circuits when priced individually. Do you know?

Because:

- Bulk production is easier.

- It requires fewer labor efforts and produces better efficiency.

- Automation and CNC machines ensure accuracy and speed during production.

- Shipping costs are divided by the overall number of items being shipped.

Order volume impacts overall costs and results in higher profits when you order a bulk quantity.

Material Selection

Material impacts prices. If you choose materials with high quality and durability, prices will skyrocket. Therefore, choose the materials that are the most affordable and effective.

Here is the overview of a few base materials.

- FR-4 is one of the most common materials with an affordable price tag. It is general and standard for the PCB circuits.

- Rogers/PTFE is ideal for aerospace PCB circuits. Therefore, their price tags are higher than those of the FR-4.

- Polyimide is an advanced material with a medium to high price range.

Copper thickness

Copper conducts electricity and performs several jobs. However, the thickness of the copper is decisive about the prices. Here is the general usage of copper.

- Standard: 1 oz (35 µm) is the default.

- Thick copper (2 oz or more) is for power electronics or high-current traces.

Thick copper is more expensive than standard one. This is due to the time required during manufacturing and the raw materials. Therefore, check the required copper thickness for your PCB circuit board price decisions.

Surface Finish

Surface finish can affect the pricing. For example, ENIG is more expensive than HASL. A quality finish can boost the appearance and decrease the graininess of materials.

Here are a few more types of finishes.

| Finish Type | Cost | Notes |

| HASL (Hot Air Solder Leveling) | Low | Basic, cost-effective |

| ENIG (Electroless Nickel Immersion Gold) | Medium–High | Flat pads, ideal for SMT, RoHS compliant |

| OSP, Immersion Silver/Tin | Medium | Environmentally friendly |

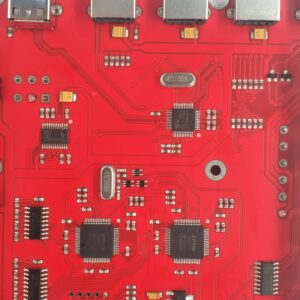

Design complexity

It is a straightforward concept that complex designs are challenging to manufacture and require more effort and money. Therefore, the PCB circuit board price is higher.

Here are a few complex designs that can raise prices by up to 300%.

- Tight trace widths (<6 mil), fine-pitch BGAs, controlled impedance, and blind/buried vias increase complexity.

- High-Density Interconnect (HDI) designs may require laser drilling, sequential lamination, and resin filling.

Lead times

How fast do you want your delivery? Prices are already at the Mount Everest if it is a peak season. If you want products fast, pay extra.

Usually, a standard lead time of 2-4 weeks offers a more affordable price. If you want the products in 1-2 weeks, you should pay 50-100% extra. Prices can jump to 200% if you want the products in 1-3 days.

Before choosing a supplier, get a PCB circuit board price for the different lead times.

Tools and setup costs

Tooling and setup costs are pretty high and can affect the overall price of the production. Here are a few one-time fees.

- DFM checks

- Drill and routing setup

- Panelization

- Solder paste stencil (for assembly)

They appear once but affect the project’s prices in the long term.

PCB assembly costs

PCB assembly costs are always there if you want to source and manufacture the components of a complete circuit with an expert.

Prices vary and include several additional costs. Look at the assembly costs as:

Component Sourcing

The first step is to source the raw materials. What is required, and where can you source it?

Here is how component sourcing involves various fees.

- Resistors, capacitors, ICs, and connectors prices add up.

- Hard-to-find or obsolete parts have a premium price.

- Suppliers often charge a markup of 5–15%.

Assembly Process

If you already have the expert onboard, that’s excellent! Otherwise, you have to hire the experts as well. They can cost a fee. Moreover, the assembly process can prepare the following fees for you.

- SMT assembly is futuristic and cheaper than through-hole.

- Double-sided placement increases labor and reflow steps.

- Special components like BGAs and QFNs require advanced equipment and inspection. It can raise price concerns.

Stencil and Reflow

A stencil can cost a lot if you prepare a unique and extraordinary design. Reflow ovens and pick-and-place machines also come at a price. You should include them in your PCB circuit board price calculation.

Testing and programming

You can’t go without testing your boards and understanding how they work under different conditions. It requires a comprehensive inspection and a few tests, such as Functional Testing (FCT), In-Circuit Testing (ICT), and firmware flashing.

All these come at a price and elevate the overall significantly.

How to reduce PCB circuit board price?

You might have encountered several price types and be worried about whom and what to choose. Is that so? Don’t worry at all. We have a few tips that help you choose the right circuit and at a better price range.

Optimize Design

Design optimization can ensure success while cutting costs. Instead of making your circuits complex, go for seamless designs with high feasibility. Here are a few tips.

- Use standard hole sizes and trace widths

- Avoid blind/buried vias and microvias

- Limit the number of layers (2 or 4 layers)

- Stick to standard materials like FR-4

Minimize Board Size

Large boards require more raw materials and are often time-consuming. Reduce the size and do the job you want to. Here are a few tips for cutting the board size and improving your savings.

- Reduce overall board dimensions

- Optimize component layout

- Use both sides of the PCB for placement

Relaxed Specs

Go for the flexibility rather than tightening the features and paying higher prices. Get the required features within your budget.

Here is how you should act.

- Use standard spacing between traces

- Avoid unnecessary precision tolerances

- Choose basic finish and solder mask specs

Order Bulk

One item is expensive than ten items if you add the costs individually. If you have higher demands for PCB circuits, go for the bulk orders. You can save on:

- Lower per-unit cost with large orders up to 100 or 1000 pieces.

- Spread tooling/setup charges on each item and reduce the costs.

- Get a cut on the shipping when it gets divided into hundreds of items.

Choose the right manufacturers

Supplier selection is the most crucial idea. You should choose suppliers who offer quality and quantity. Follow the tips below to save the right amount of money.

- Compare quotes from multiple suppliers

- Consider reliable overseas manufacturers for prototypes

- Look for bundled fabrication + assembly services

Conclusion

Choosing an affordable printed circuit board is necessary for the long term. However, you should never sacrifice quality for the sake of price. Therefore, purchase PCBs from top suppliers who offer a good balance of quality and price.

Do you want a top-rated supplier for your PCB circuits? UET PCB is the number one choice for PCB prototypes and circuits. We don’t compromise on quality and deliver premium circuits that last longer and are pretty accurate in their functionality.