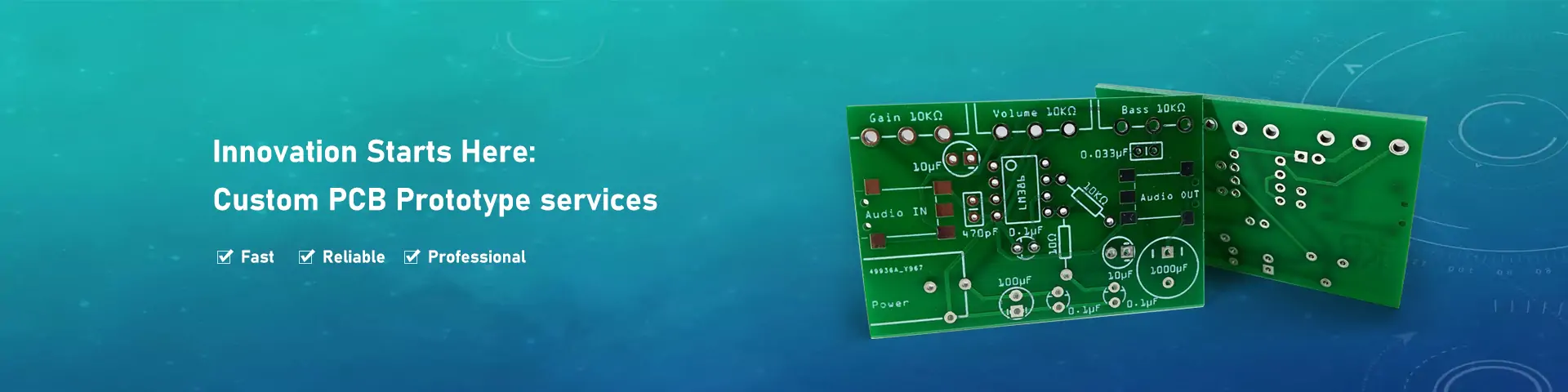

Pcb prototype service introduction

Component assembly

China PCB Assembly Manufacturer

UETPCB is a professional pcb supplier & pcba manufacturer in Shenzhen. We focus on providing high-quality PCB assembly services. As a reliable PCB supplier, we provide one-stop service from PCB manufacturing to assembly. Our professional team has the experience and skills to meet the needs of various industries. Our goal is to be your preferred partner in China PCBA manufactory. If you need quality PCB assembly services, please contact us.

Choose Your Custom PCB Project

| Features | Available |

|---|---|

| Sizes | Maximum 610*1100mm / Minimum 5*6mm |

| Quantity | 1-1million pcs |

| layers | 1-48 layers |

| Min. Line Width | 0.076mm/3mil |

| Min. drilled hole size | 0.08mm [0.003″] |

| Min. line spacing | 0.075mm (3mil) |

| Copper Thickness | 1oz—13oz 0.25oz-10.0oz |

| Base Material | Aluminum, FR4, Flex, Flex-rigid, HDI, Rogers, etc. |

| Board Thickness | ≥0.1mm |

| Surface Finish/Treatment | HALS/HALS lead free, Immersion gold, OSP, Hard Gold, ENEIG, Immersion sliver, etc |

| Finish Cooper | 1-13oz |

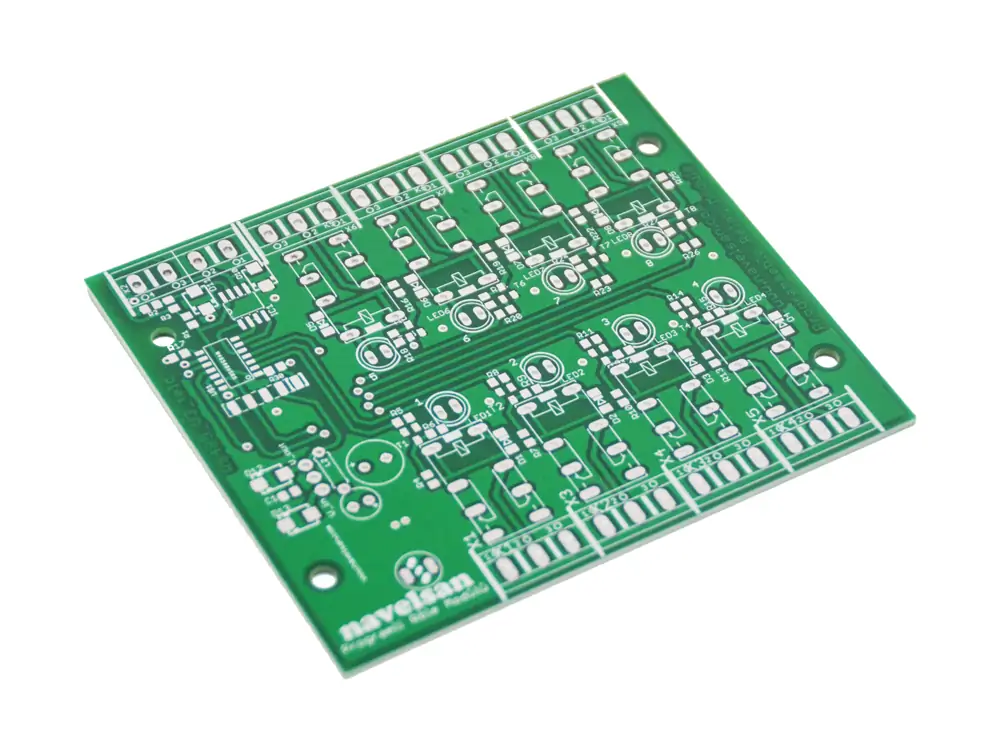

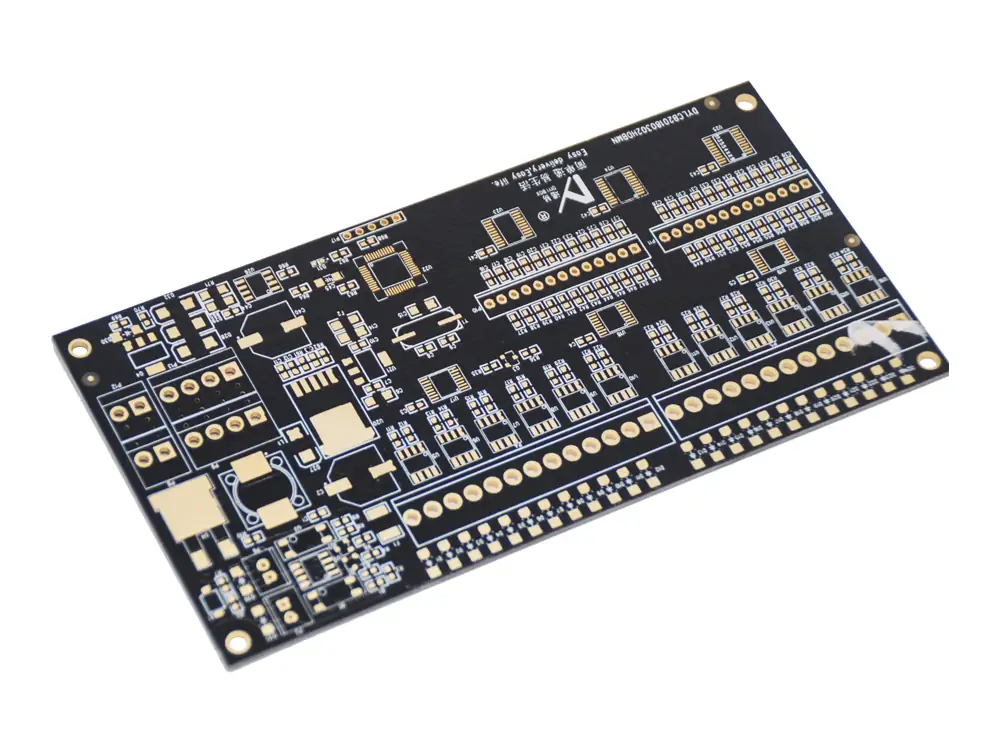

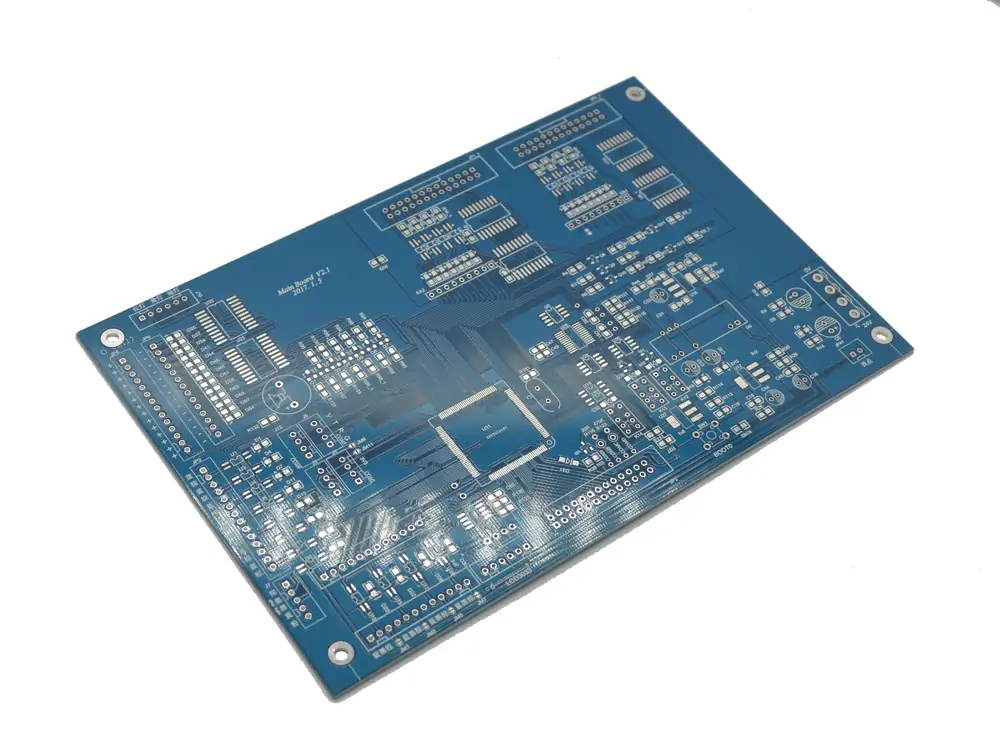

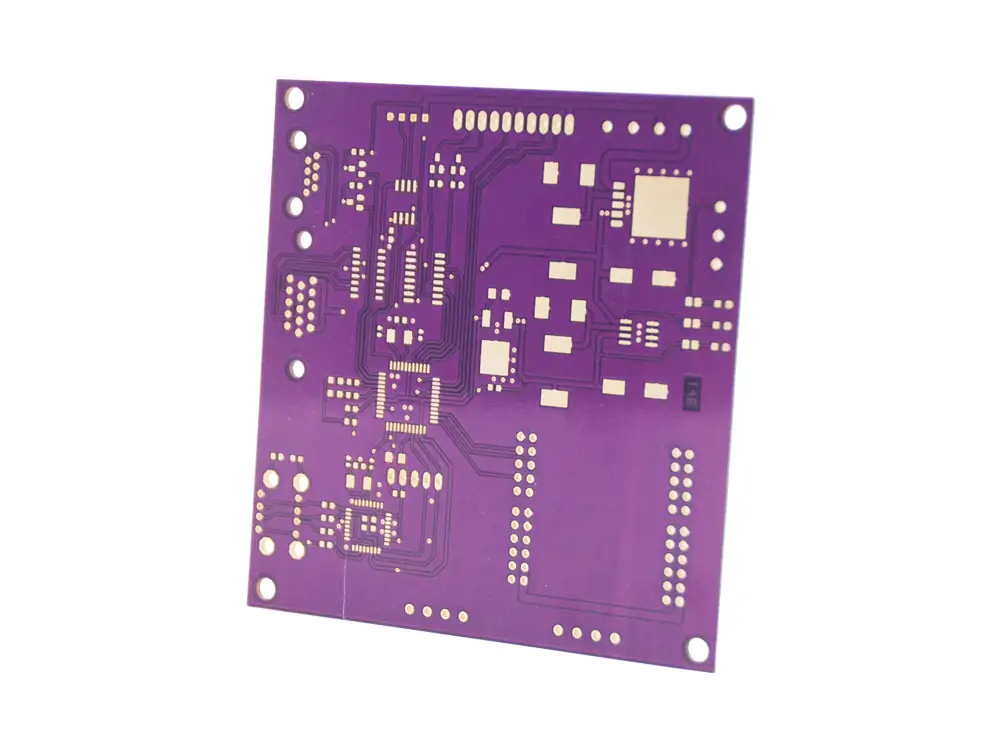

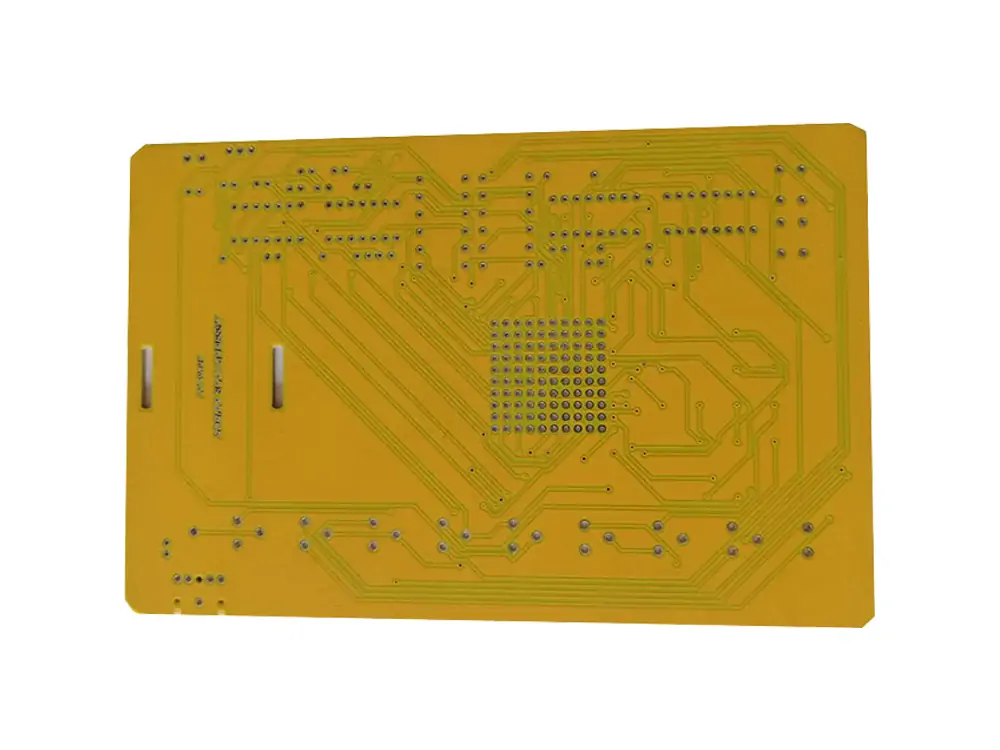

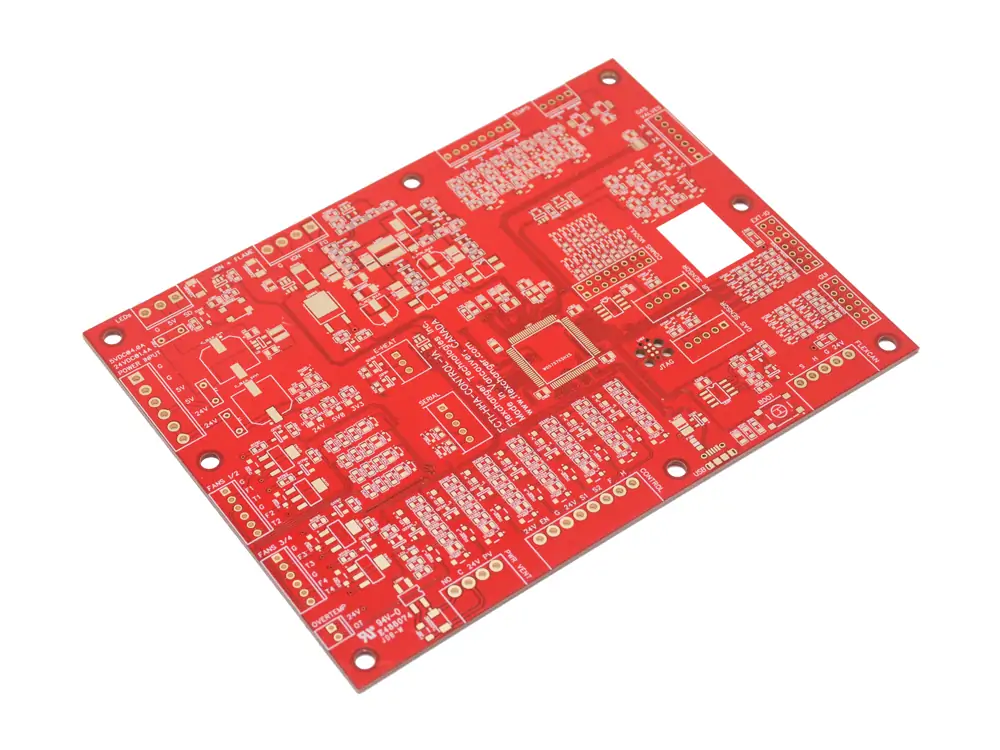

| Solder Mask Color | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green |

| Silkscreen | White, Black |

| Testing | Fly Probe Testing (Free) and A.O.I. testing |

| Build time | 24 hours |

| Lead time | 2-3 days |

PCB Types Details

Choose the Right PCB Layers

Common PCB layers include single-sided, double-sided, and multi-layer boards. When choosing, consider the complexity of your circuit. Simple circuits use single or double-sided boards. Complex circuits benefit from multi-layer boards.

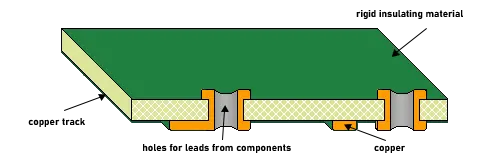

Single Side PCB

Single-Side PCB is the simplest and most common type of PCB. It was the first device used for the interconnection and assembly of electronic components forming a cohesive and functional operating system. The primary industry that uses these boards is the consumer electronics industry.

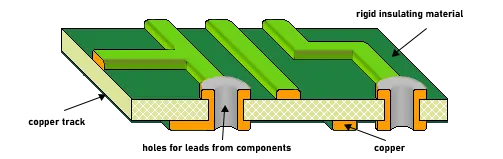

Double Side PCB

Double Side PCB have made circuit in 2 layer of different PCB side that both layer has connect by via PTH (Plated Through Hole) which depend on design this is more complex than Single Side PCB.

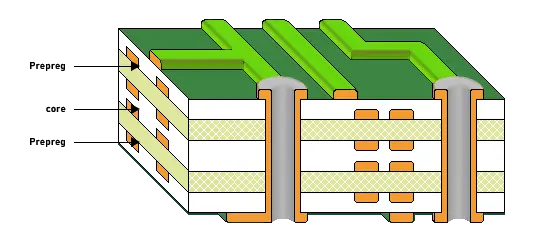

Multi Layer PCB

Multi Layer PCB have more layer than double side PCB, it has many circuit layer between Top side and Bottom side of PCB and also each layer can connect with via PTH (Plated Through Hole), this type is more complex than double side PCB.

Rigid PCB

“Rigid PCB” is a circuit board used in electronic equipment that is characterized by being strong and not prone to bending. This type of circuit board usually consists of multiple layers of fiberglass reinforced material (such as FR-4) and layers of conductive copper. They are a critical component of electronic products and are used to provide stable and reliable electrical connections. Rigid PCBs are widely used in computers, mobile phones, home appliances and other high-performance electronic devices and are favored for their excellent mechanical stability and heat resistance. Compared to flexible PCBs, they are better suited to withstand high pressure and high temperature environments.

Aluminum Board

“Aluminum Board” is a special type of printed circuit board (PCB) that uses aluminum as its core material. Aluminum PCB is widely used in electronic products in high-power and high-temperature environments due to its excellent thermal conductivity and heat resistance. These boards typically consist of a thin layer of aluminum, a conductive layer such as copper, and an insulating layer. The main advantages of aluminum plates include a lower coefficient of thermal expansion and better heat resistance, which helps increase the life and stability of electronic components. They are commonly used in LED lighting, automotive electronics, power equipment and other fields, and are favored because they can effectively dissipate heat.

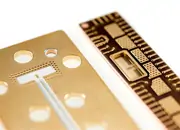

Rigid-Flex PCB

“Rigid-Flex PCB” combines the characteristics of rigid PCB and flexible PCB to provide unique versatility and reliability. This circuit board consists of a rigid part and a flexible part, allowing it to be used in some applications that require bending or folding, while maintaining some areas of rigidity. Rigid-flex hybrid PCB allows for more complex designs and innovative electronic product layouts, making it ideal for electronic devices with limited space or requiring three-dimensional assembly. They are widely used in advanced consumer electronics, military and medical devices and are valued for their ability to provide excellent electrical performance and mechanical flexibility.

Metal Core Board

A “Metal Core Board” is a printed circuit board with a metal core, usually using aluminum or copper as the center layer. The main advantage of this PCB is its excellent thermal conductivity, allowing it to effectively dissipate the heat generated, especially in high-power LED applications and power converters. Metal core boards are more effective at handling thermal stress than traditional PCBs made of FR-4 or other non-metallic materials, thereby improving overall device performance and reliability. They are often used in applications that require high thermal management, such as lighting systems, automotive and renewable energy systems.

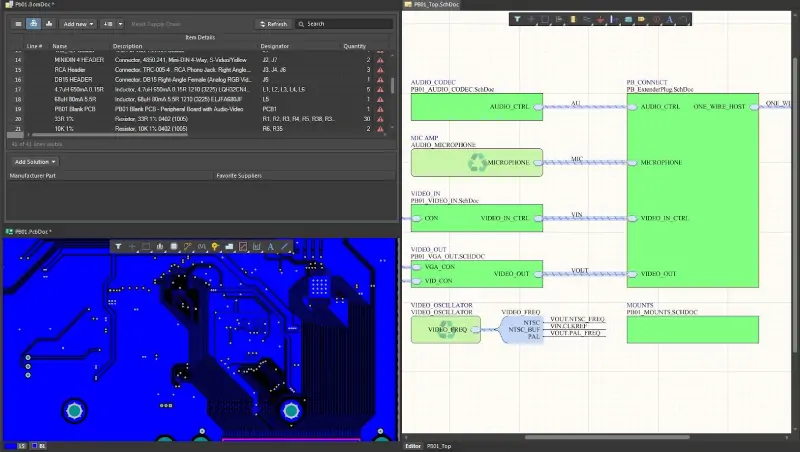

Gerber file (RS-274-X)

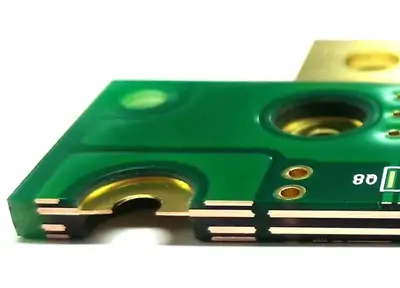

PCB prototype

We offer all the PCB services you need, including printing circuit boards. We support five file formats for PCB fabrication: gerber, .pcb, .pcbdoc, .cam, or .brd.

Gerber file format: RS-274-X

- · GTL Gerber top layer

- · GTO Gerber top overlay

- · GTS Gerber top solder

- · GBL Gerber bottom layer

Gerber file naming

- · GBO Gerber bottom overlay

- · GBS Gerber bottom solder

- · GKO Gerber keepout layer

- · DRD Excellon drill file

PCB Fabrication Process

Step 1:Creating a designed layout on the copper-clad laminate

Step 2:PCB manufacturers will etch or remove excess material from inner layers to reveal images and pads.

Step 3:Laminating printed circuit board materials at high temperatures for creating the PCB layer stack up

Step 4:Creating mounting holes, through-hole pins, and vias on PCB

Step 5:Etching and removing the excess copper of the surface layer to reveal images and pads

Step 6:Placing plating pin holes and via holes

Step 7:Creating a protective coating or solder masking on the surface

Step 7:Silkscreen printing, logos or other markings, and installing polarity indicators on the surface

Why Choose UETPCB as your Rapid Prototyping Manufacturer?

Select UETPCB as your rapid prototype manufacturer for a seamless experience. Our commitment to quality and efficiency ensures your project’s success. We offer high-end equipment, experienced engineers, and aligned production. All these factors can turn your designs into functional prototypes .

We have a proven history of being accurate and dependable. Choose us to make your ideas come true. From PCB design to rapid assembly, we provide end-to-end services. So, choose UETPCB for cost-effective prototyping.

Custom PCB Service

We have fifteen years of custom PCB manufacturing experience. Our experienced engineering team created our advanced machines. They meet a variety of high-difficulty and high-precision PCB manufacturing.

We keep the complete set of precision automation equipment. We keep Universe VCP, advanced laser /mechanical drilling, and automatic silkscreen exposure machines. Also, we have LDI high-precision exposure and AOI machines. These top-notch automation equipment provide high-quality guarantees for customers.

Select High-End Materials

Selecting reliable brand materials ensures product quality and controls the production process. Standard material are FR4 (Shengyi, ITEQ, KB, Nanya). High-frequency materials are Rogers、Taconic、Nelco、Arlon 、Isola、F4B、TP-2. High-Tg materials are Shengyi S1000‐2, S1170, KB. Halogen-free materials are EMC EM285, EM370(D), Shengyi S1155、S1165.

Leading PCB Production Capacity

We can have up to 48 layers in our design. The maximum weight of copper is 10 ounces. The smallest size for mechanical drill holes is 0.1mm with an accuracy of +/- 0.05mm. We have unique methods like controlling impedance and using buried/blind Vias. We also place Vias in the pad and do edge plating. We specialize in half-cut/castellated holes, countersinks/counterbores, and press-fit holes. Moreover, these techniques also include heavy copper, hard gold, custom Stackup, and more.

Pcb Quality Management System

When you use the IPC quality management system, you are guaranteed a 100% product qualification rate. All PCB boards are 100% electric tested to provide high-quality PCB board products. Continuous improvement of quantity, technology, and service meets customers’ expectations.

Fast Turn Times Of PCB Prototype

Using an ERP order management system, clear production control ensures on-time delivery. This system also includes a rigorous production process for quick delivery.

The fastest expedited PCB prototype order we can do is 12 hours. We also provide customized PCB orders with 99% On-time delivery.

Security and efficient shipment ensure on-time delivery.

Complete PCB Services

Provide 7×24 hours of technical support for PCB design and PCB manufacturing. One-stop services from design to production significantly shorten the customer’s development cycle. One-to-one VIP service for pre-sales and after-sales

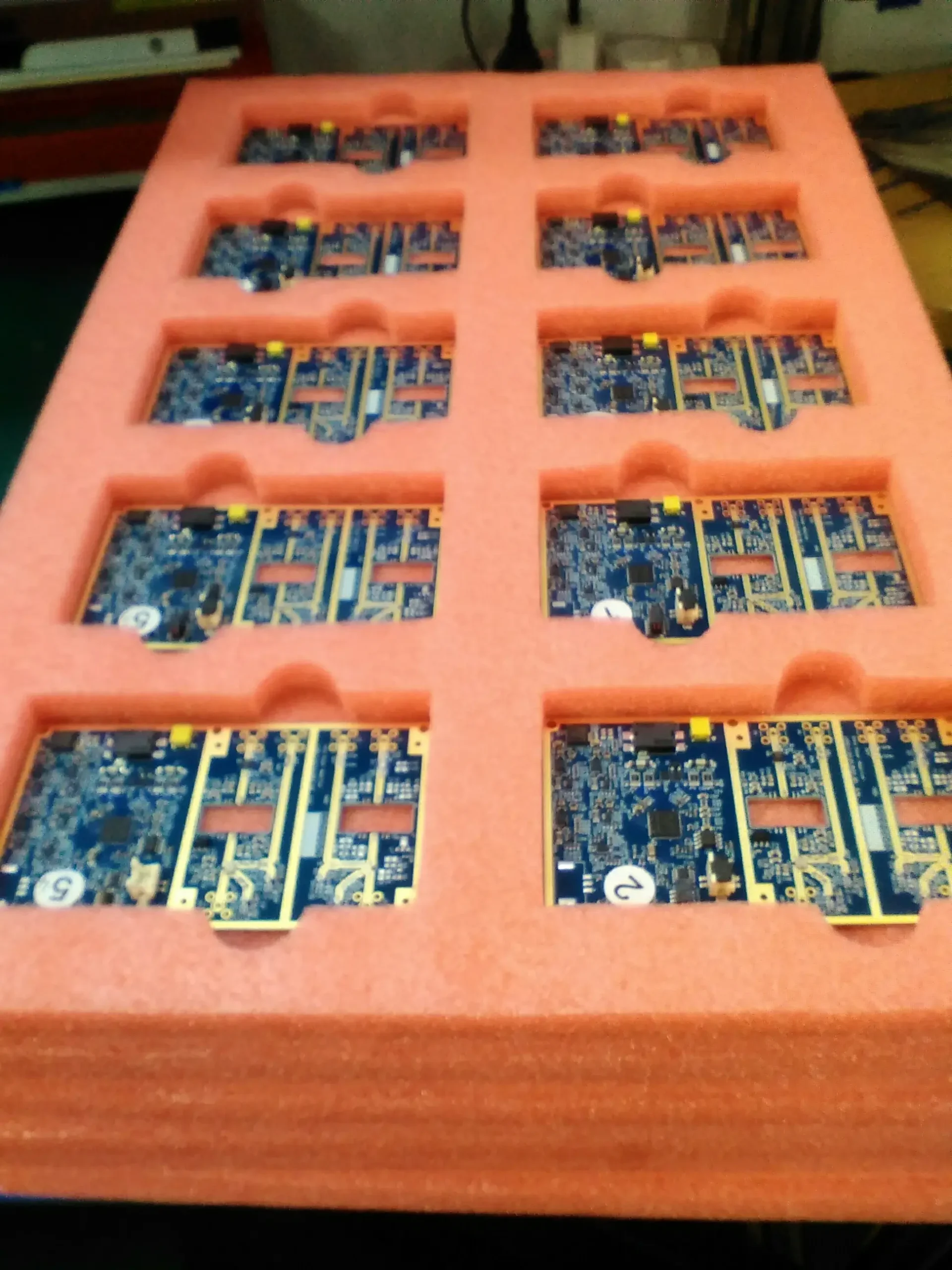

Our Packaging

What Our Customers Say About Our PCBA Services

FAQ

Prototype PCB assembly is crucial for various reasons. The primary reason is that it enables trial & error before mass production. Prototype assembly verifies product design and identifies flaws. Engineers can make necessary adjustments based on the result data and reduce potential losses. This process performs several testing and refinement of the circuit’s functionality. As a result, it ensures that the manufactured produce meets performance & quality standards.

UETPCB specializes in world-class PCB assembly services. We focus on precision and quality. As a result, our products are trusted by customers from all over the world. However, our prototype PCB Assembly services include:

-

DFM Analysis:

DFM stands for Design for Manufacturing. This service involves a comprehensive analysis by engineers. Through this process, they ensure that the design is optimized for efficient manufacturing.

-

PCB Prototype Services Or Custom PCB Services:

This service includes multiple solutions. These solutions include PCB proofing, prototype development, and manufacturing.

-

Components Sourcing:

This service involves procurement of electronic components. A reliable component sourcing ensures that the prototype meets quality & specification standards.

-

Prototype PCB Assembly:

This service provides a quick prototyping service for patches. It allows for the testing of PCB designs. Ultimately, it ensures that the part is functioning as intended.

-

PCBA Testing:

This service involves multiple testing processes. All these services ensure the quality and functionality of the assembled PCBs.

-

Flying Probe Testing:

A non-contact test method uses a robotic problem. The process checks PCB connectivity and identifies faults without test fixtures.

-

In-circuit Testing

is an automated process to evaluate individual component functionality. It helps in detecting defects in assembled PCBs.

-

X-ray Inspection:

It is also a non-contact testing method that uses X-rays to check hidden solder joints. It also checks the internal connections and components on PCBs for quality & integrity.

-

AOI stands for Automated Optical Inspection.

The purpose of AOI is to detect defects to ensure quality assurance.

-

Functional Testing:

This method verifies that a product or component performs as intended. It also ensures it meets design & performance criteria.

-

Visual Inspection:

This method involves a manual examination of the produced part. The purpose of this method is to identify visible defects.

It’s easy and convenient to start a quick proofing process at UETPCB. You can simply contact our customer support, who will guide you through the process. A quick proofing service can be simplified into the following key stages:

- Quotation & Order Intake: You can request a quote easily. We confirm your order with clear pricing & specifications.

- Production & Quality: After the order confirmation, you can submit your design if you have one. Later, our engineers will evaluate the design and make necessary changes. After that, your prototypes are produced according to your requirements.

- Sample Testing & Feedback: We will conduct several testing processes after making the prototype. It ensures that your prototype meets all your specifications. So, you will receive thoroughly tested prototypes. Later, we will evaluate your feedback and make necessary adjustments.

- Packaging & Shipment: You can completely trust our packaging & shipment process. We take care of securely packing your prototypes and use dependable shipping methods.

We’re Here To Help You

Any questions? Contact us anytime, and we’ll respond to your inquiries within 24 hours.

We specialize in building your pcb prototype and PCB assembly with rapid turn times.