PCB thickness determines a circuit board’s strength, performance, and durability. It also ensures proper heat dissipation in a circuit. A PCB thickness tolerance tells you the allowable thicknesses for a perfect fit. In this article, you will specifically learn about PCB thickness tolerance. There are different tolerance values for different PCB thicknesses.

Overview of PCB Thickness Tolerance

Tolerance is a very important factor in manufacturing. It refers to the allowable boundary. Regarding PCB thickness tolerance, there are permissible variations in thickness. You will need this PCB thickness tolerance to fit the PCB perfectly in your electronic gadget.

Every PCB factory follows a standard for this tolerance value. Let’s take an example. If a PCB thickness is 1.6, according to the thickness tolerance chart, the tolerance is ±0.14 mm. This means your PCB can vary by 0.14 mm more or less than the nominal value.

You can refer to the following table to determine your PCB’s thickness tolerance. However, this value may change in different factories. So, if you jump into final production, you must know which standard the factory follows.

| PCB Thickness | PCB Thickness Tolerance |

| Less than or equal to 1.0 mm | ±0.10 mm |

| Less than or equal to 1.6 mm or greater than 1 mm | ±0.14 mm |

| Less than or equal to 2.0 mm or greater than 1.6 mm | ±0.18 mm |

| Less than or equal to 2.4 mm or greater than 2 mm | ±0.22 mm |

| Less than or equal to 3.0 mm or greater than 2.4 mm | ±0.25 mm |

| Greater than 3 mm | ±10% |

In addition to the table above, other tolerance values are related to PCB thickness. The tolerance for lamination is ±8%. On the other hand, the tolerance of the finished board is ±0.1 mm to ±0.3 mm.

Industry Standards for Printed Circuit Board Thickness Tolerance

Several standards are used in PCB manufacturing. IPC 6012 explicitly discusses PCB thickness.

IPC 6012 standard defines the need for board quality and performance. In this standard, there are three main classes of PCBs.

The Class 1 PCBs are generally ideal for regular electronics products. These PCBs meet the basic performance standards.

On the other hand, class 2 PCBs offer more reliable performance. They are prevalent in consumer electronics.

Finally, class 3 PCBs provide much higher performance. They are prevalent in medical, aerospace, modern manufacturing, and other industries.

How to Control Thickness Tolerance in Circuit Board Manufacturing

We always expect high accuracy and tolerance values. However, to get such standards, you must employ better manufacturing techniques. Regarding PCB thickness tolerance, you can pay attention to three factors:

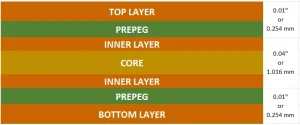

First, lamination is one of the key processes. It generally bonds the layers of the PCB under heat and pressure. If you can control the temperature and pressure properly, you can ensure uniform PCB thickness.

The second factor is the copper plating, which adds thickness to the final PCB. You must control this method to optimize the PCB thickness tolerance. Finally, planarization is used after lamination and copper plating. Techniques like sanding or buffing help smooth and flatten the surface.

How to Measure and Check PCB Thickness?

You can measure the PCB thickness in various ways. The easiest way is to use mechanical micrometers, which are easy to get and can be found in nearby shops. You can also use laser thickness gauges and X-ray Fluorescence (XRF).

The second two options are difficult to find. You can only find these tools in testing facilities, not easily in nearby shops. You have to pre-order and ship them to your country.

Contact Us Today!

If you are looking for high-quality and high-tolerance PCBs, contact us today. If you have any questions, please leave them in our customer support section.