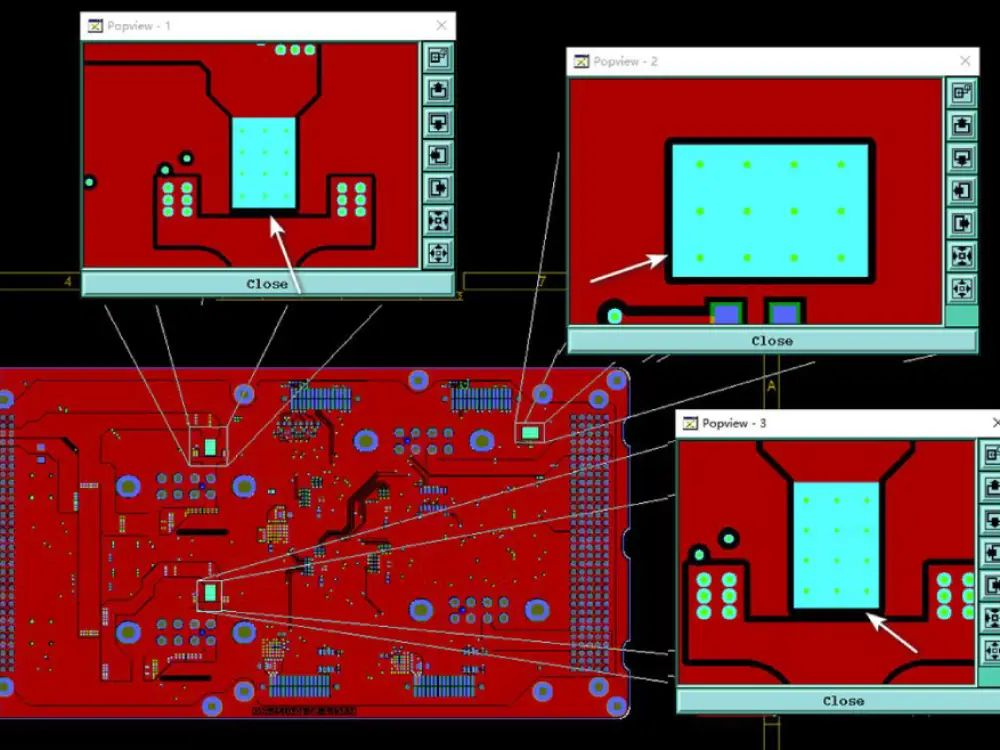

DFM Checking

Our engineering team performs a feasibility review of your design files (e.g., board edge clearance, trace routing, drilling, pad spacing, impedance, stack-up) prior to production.

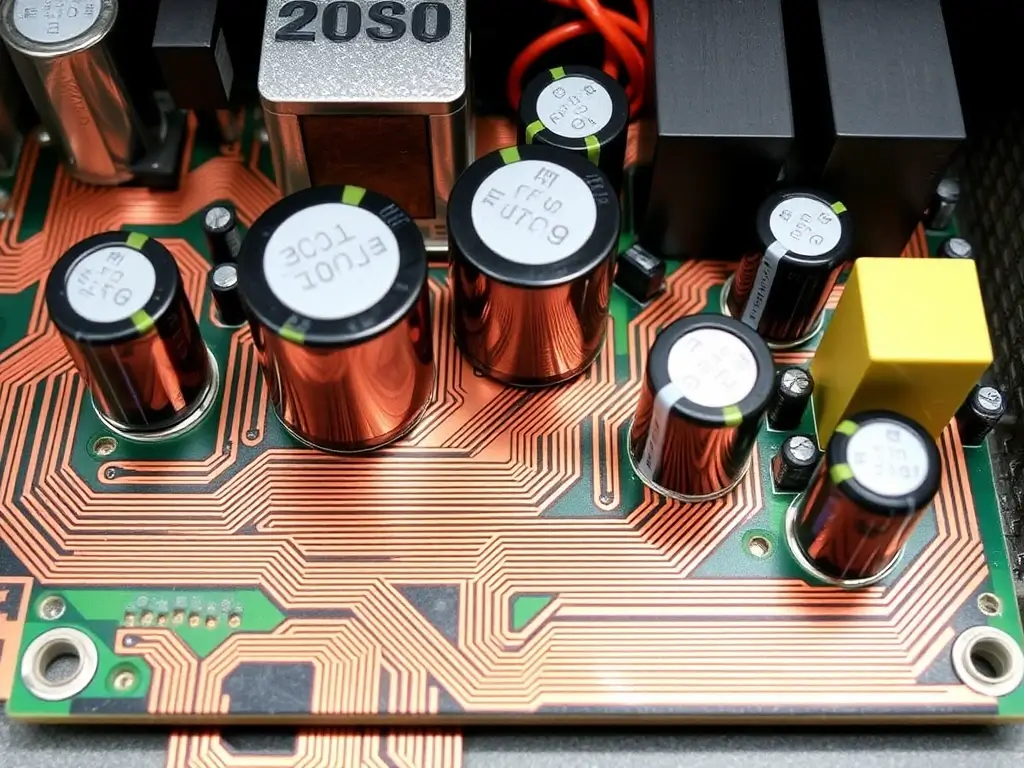

Raw Material Guarantee

We source materials exclusively from industry-leading suppliers (e.g., KB, Shengyi, Rogers) and rigorously inspect them per international standards and customer specifications to ensure product durability and stability.

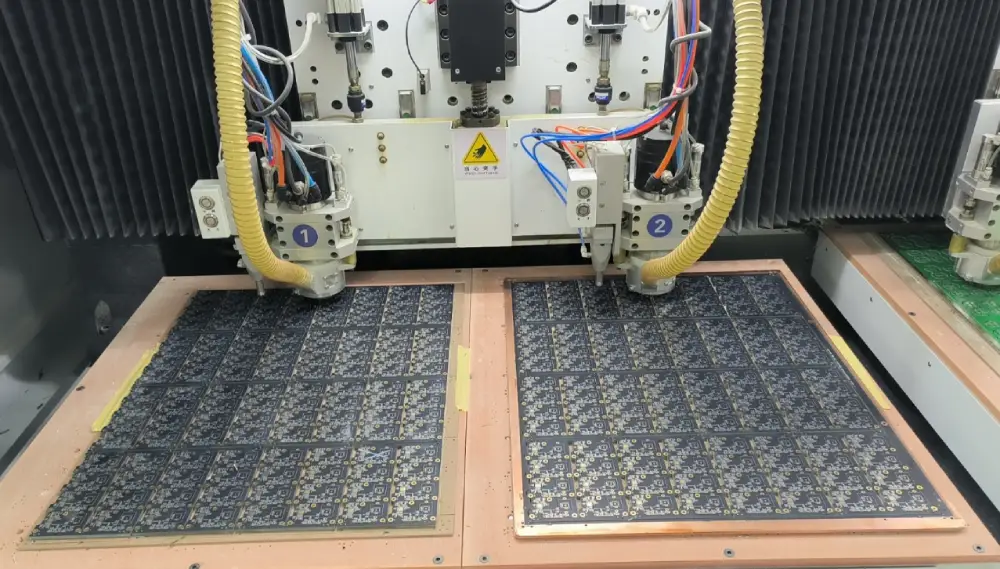

AOI

Uses high-resolution cameras to capture and analyze PCB images for defect detection.

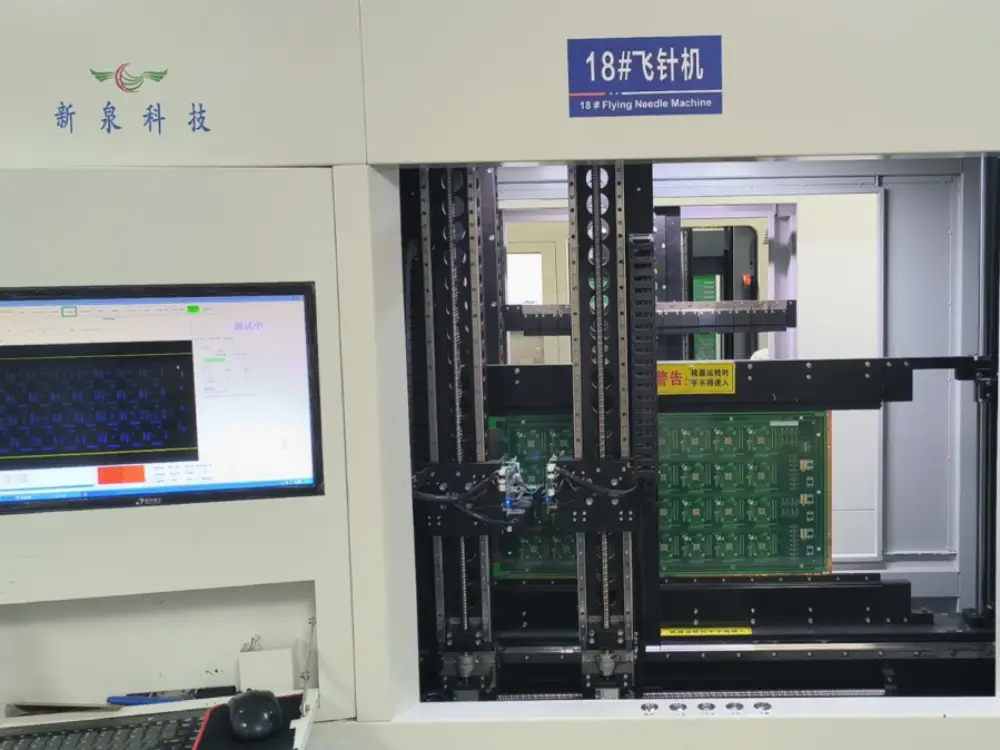

Flying Probe Test

Verifies circuit continuity (open/short) and measures electrical parameters (resistance, capacitance, voltage) by contacting test points with movable probes according to programmed instructions.

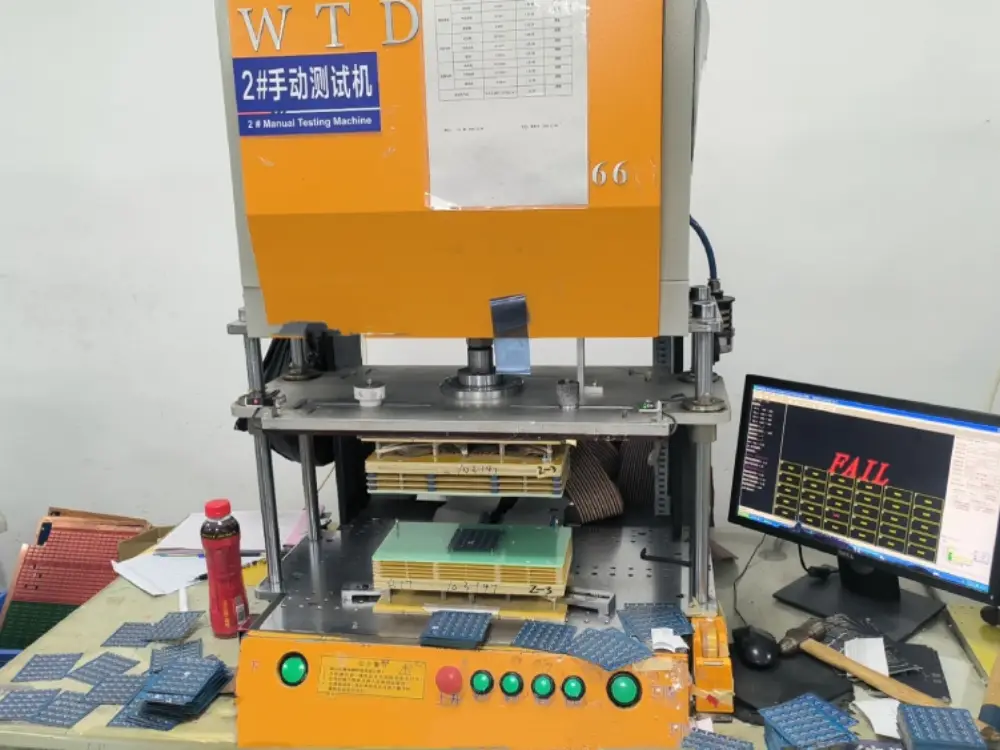

Fixture-Based Test

Employs custom fixtures with precisely aligned test pins to rapidly verify circuit net connectivity.

FQC Inspection

Conducts the final inspection, checking for functional defects and ensuring the PCB’s appearance meets all standards and specifications.