UETPCB is a professional single-sided PCB manufacturer. We are committed to providing high-quality customized circuit board solutions to customers. We have high-tech production equipment. We also have an experienced team. They can meet the needs of many industries, such as electronics, communications, and medical.

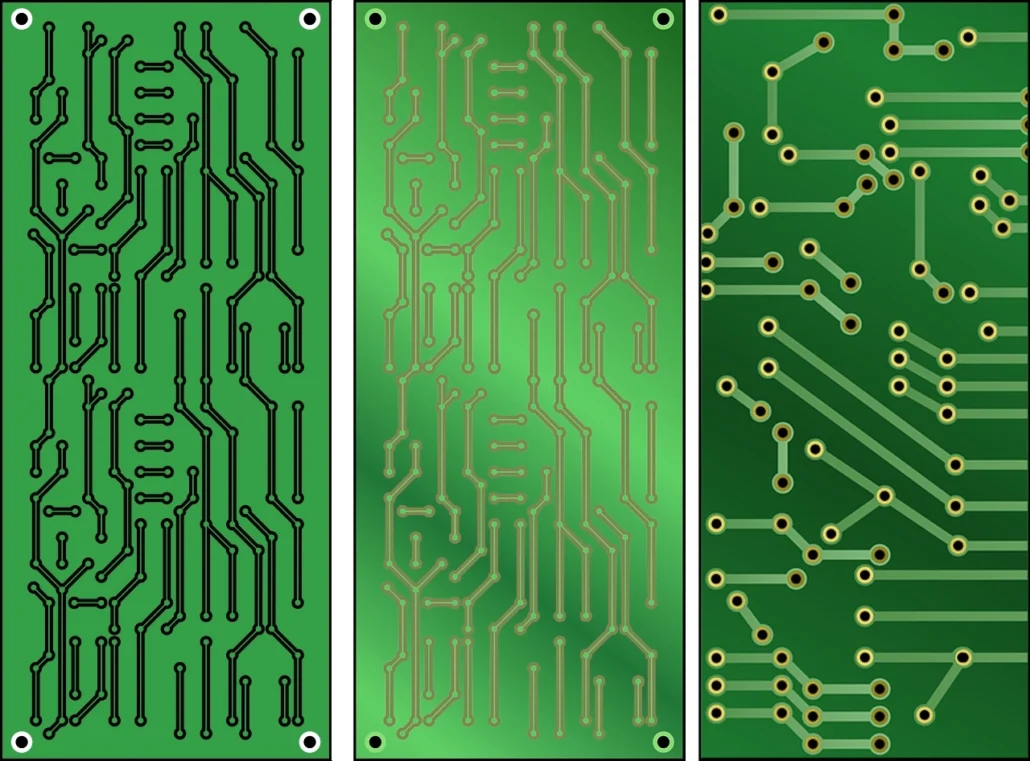

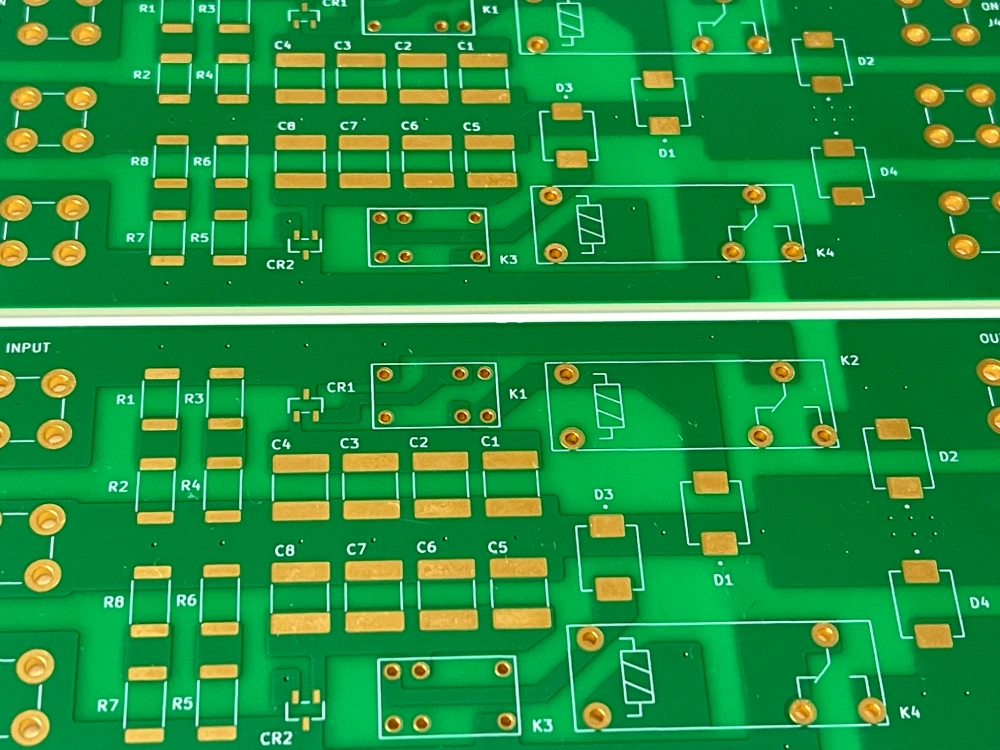

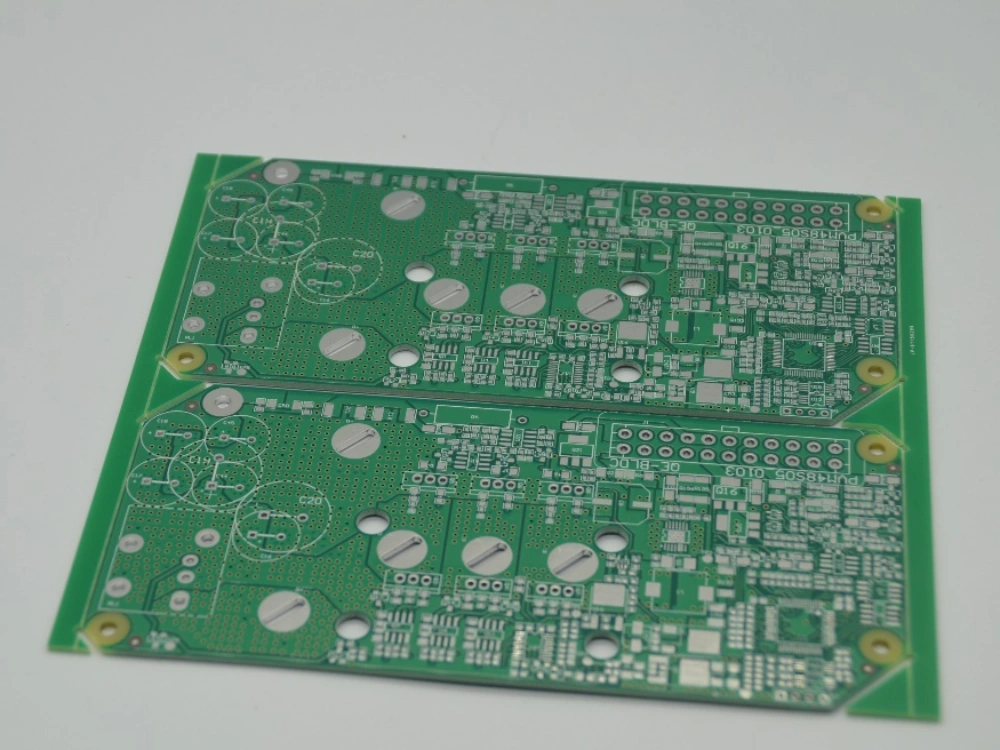

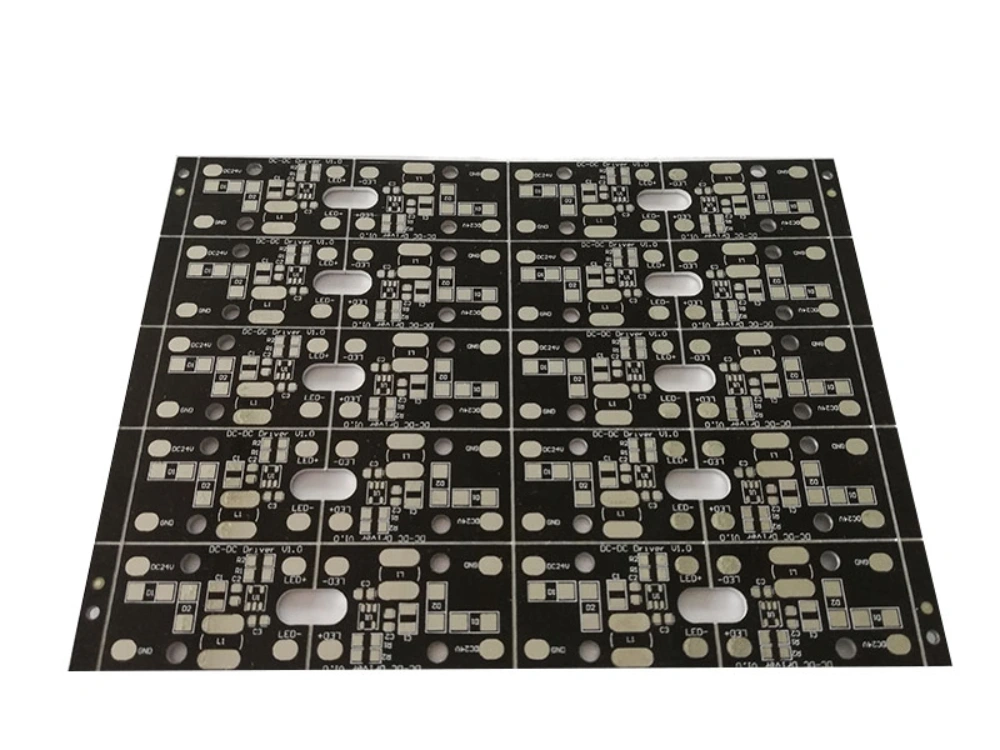

Single Sided PCBs

The single-sided PCB is an abbreviation for the single-sided printed circuit board.

It is an essential part of the production and operation of electronic equipment. Single-sided PCB is the most basic PCB.

Its parts are on one side, and the wires are on the other side.

Single-sided circuit boards have many strict restrictions on circuit design.

Because it has only one side of the circuit placed, the wiring must not intersect and be independent wiring.

So, designing its heat dissipation function will be very good.

The process of single-sided printed circuit boards has become a classic process. Its processing technology is improving, and its use is expanding.

Our Single Sided PCB Services

We provide professional single-sided PCB production services. We have advanced production equipment and an experienced team. They are dedicated to providing customers with high-quality, reliable single-sided PCBs. Our Single Sided PCB production services include:

1. High-quality material selection:

We use high-quality materials to ensure product stability and reliability.

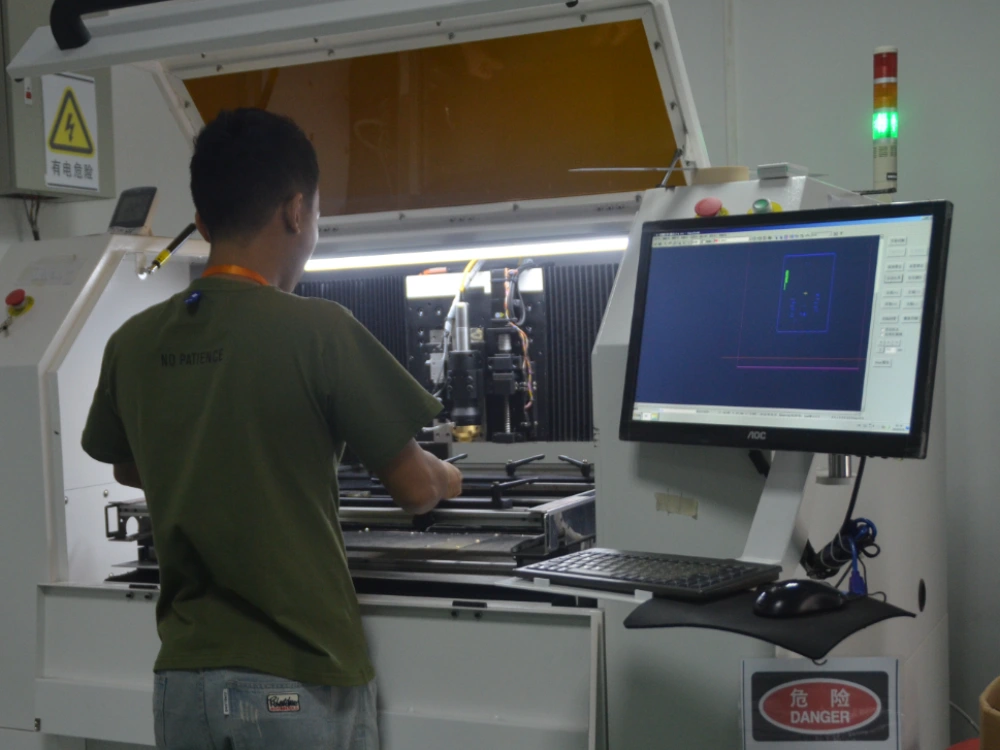

2. Precision manufacturing process:

We use an advanced manufacturing process. It helps us make high-precision single-sided PCB and ensures quality.

3. Strict quality control:

We set quality control standards. They ensure each single-sided PCB meets customer needs.

4. Fast delivery:

We focus on time efficiency and provide fast delivery services to meet customers’ time requirements.

Whether you need a high-quality single-sided PCB PCB solution or are looking for a reliable partner, we have what you require. Contact us and let us work together to provide professional technical support and quality services for your project!

High-quality material selection

Precision manufacturing process

Strict quality control

Fast delivery

Advantages of Single Layer PCB

Low Cost

Single-sided PCBs are usually cheaper than multi-layer PCBs

Simple Design

Single-sided PCB has only one circuit board layer, and the design is simple and suitable for simple circuit wiring.

Easy to Manufacture

Single layer PCBs are easy to manufacture due to their simple design, which involves only one layer of conductive material and components.

Suitable for simple applications

For low-simplicity applications, single-sided PCBs can meet the needs.

Easy to Repair

Repairs and troubleshooting are easy because there is only one circuitry layer.

Lightweight and convenient

Single-sided PCBs have a simple structure and are lightweight, making them easy to carry and install.

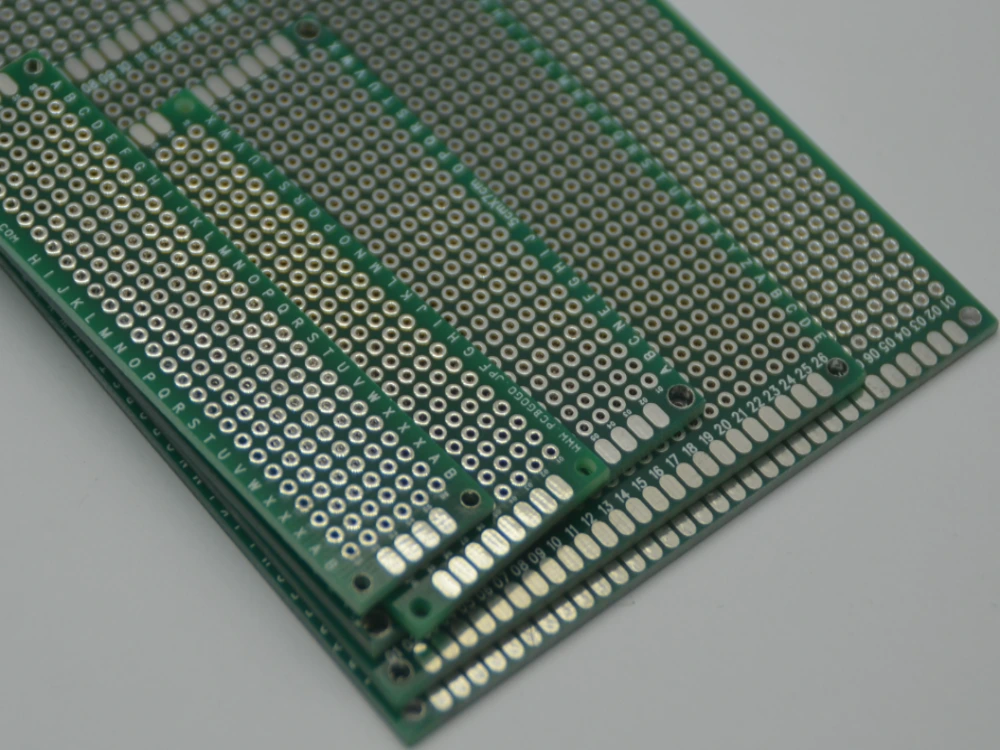

Single Sided PCBs Production Materials

The materials used in circuit boards may different. Copper-clad laminates are the primary material used in single-sided printed circuit boards. The copper-clad laminate comprises a substrate, copper foil, and adhesive.

Copper-clad laminates come in a variety of shapes and sizes. Different insulating materials include paper base, glass cloth base, and synthetic fibreboard. Binder resins fall into the phenolic, epoxy, polyester, and polytetrafluoroethylene categories.

Common materials include:

● Metal

● FR-4

● Polyimide

● Teflon

● CEM

We can pick single-sided circuit board materials for daily use. To buy large quantities, you must first examine the material’s durability. In short, there are several material options. How you choose depends on your own needs.

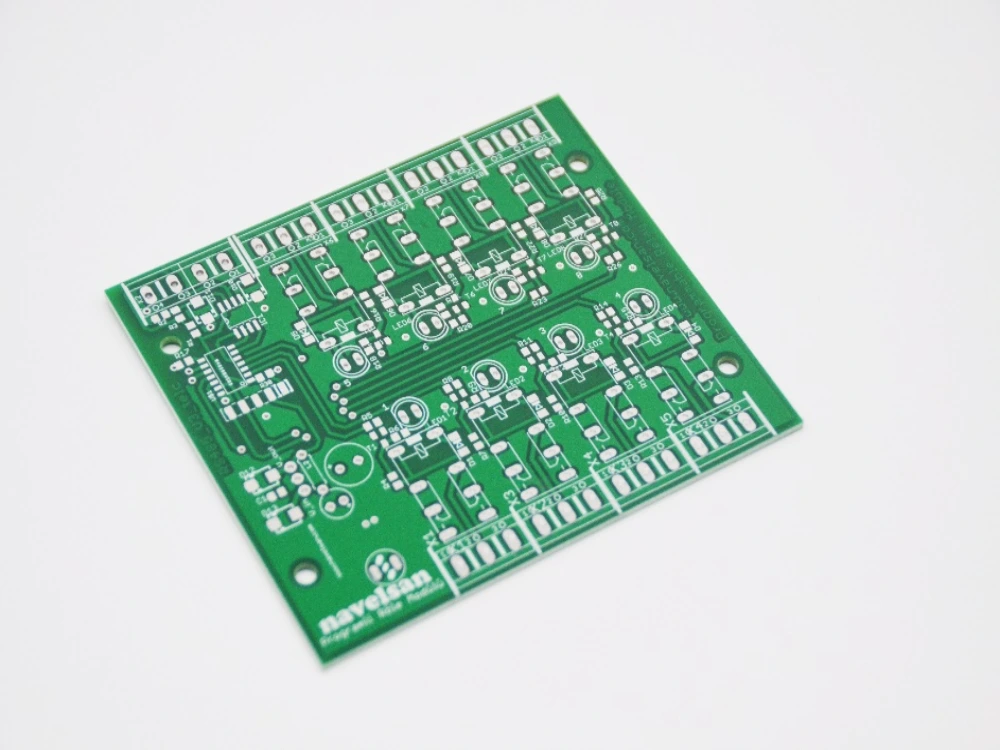

Production Process of Single-sided PCBs

- 1) Order Placement and DFM Check:

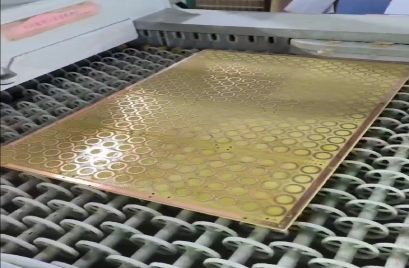

First, you place an order for the PCB. Then, we conduct a Design for Manufacturability (DFM) check. It ensures the design meets the manufacturing requirements. - 2) PCB Board Cleaning and Cutting:

The workers clean the raw PCB material to remove impurities and cut it to the required size. - 3)Drilling and Cleaning:

We drill holes into the PCB for component insertion and clean the board to remove debris. - 4) Electroplating:

To enhance conductivity, we deposit a thin copper layer onto the PCB’s surface. - 5) Copper Plating:

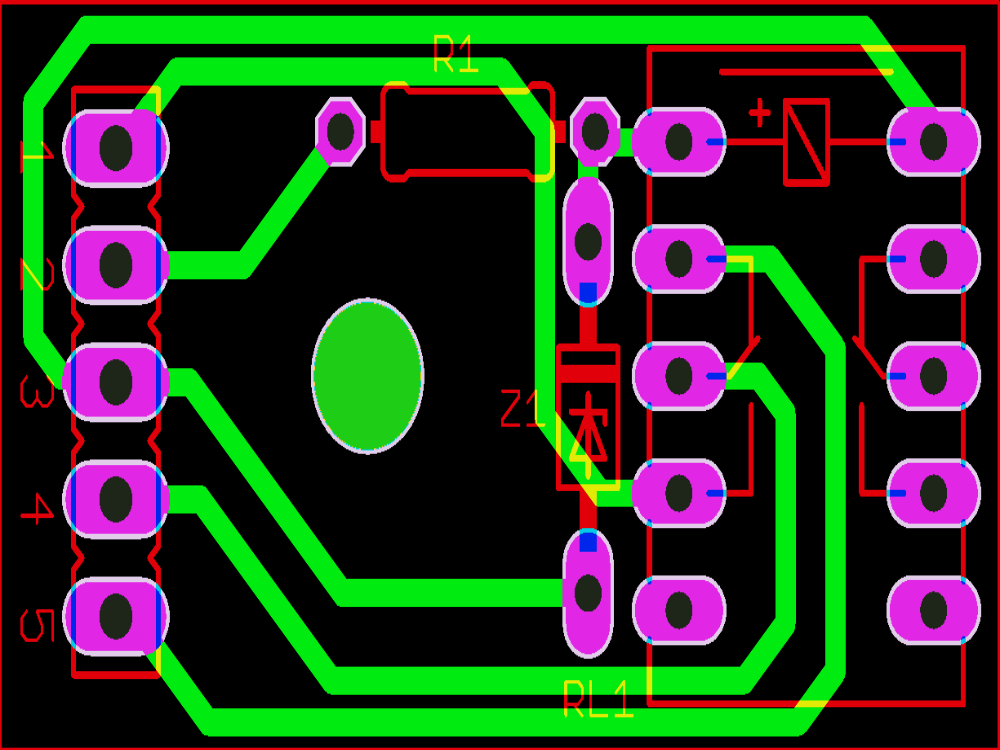

We perform more copper plating to create the circuit pattern on the board. - 6) Circuit Printing:

A special etch-resistant ink prints the circuit pattern onto the copper layer. - 7) Etching:

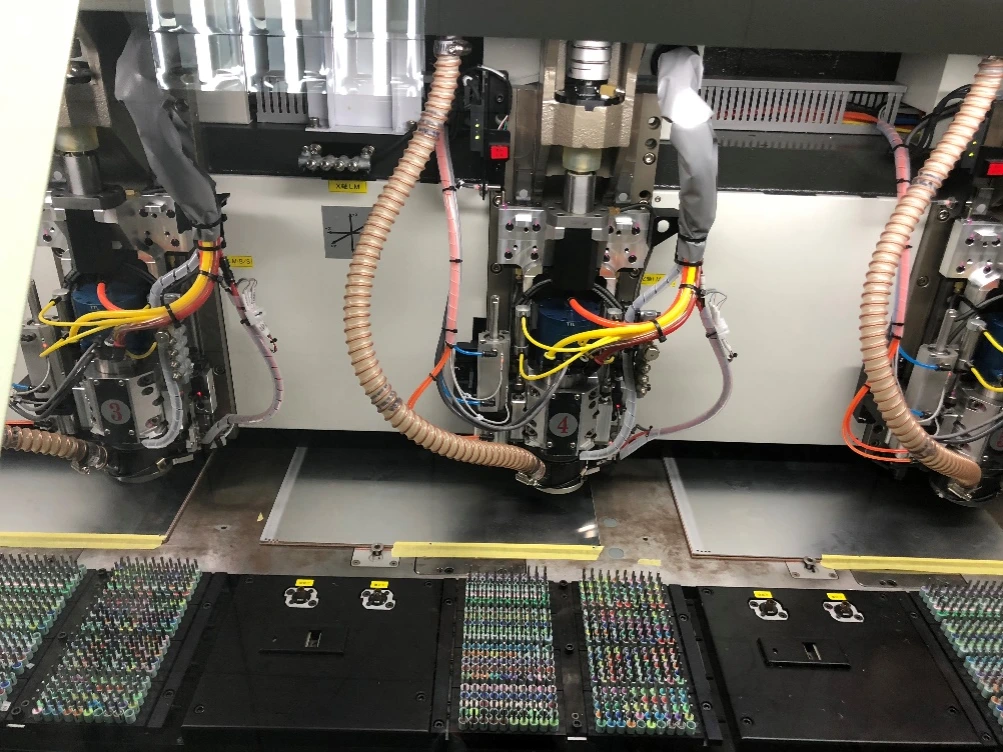

Etching away the unneeded copper leaves behind the circuit traces. - 8) Automated Optical Inspection (AOI):

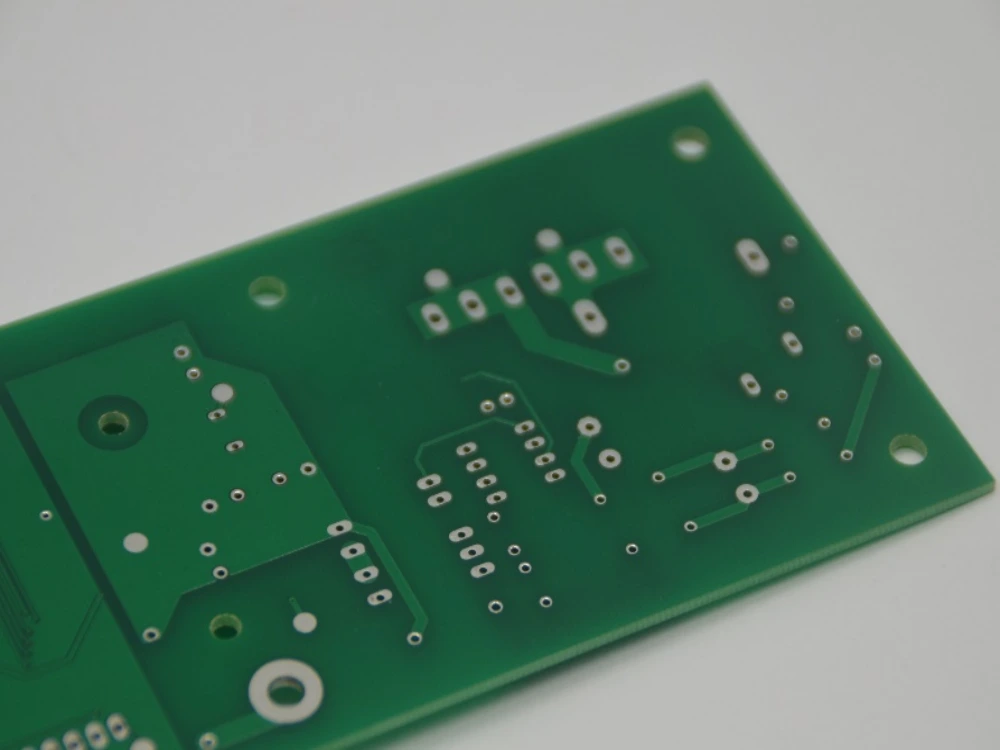

Inspectors use automated optical inspection to check the PCB for any defects in the circuit pattern. - 9) Solder Mask:

A solder mask protects the circuit traces and provides insulation between components. - 10) Silk Screen:

A silk screen prints component labels and other markings onto the PCB. - 11) Surface Finish:

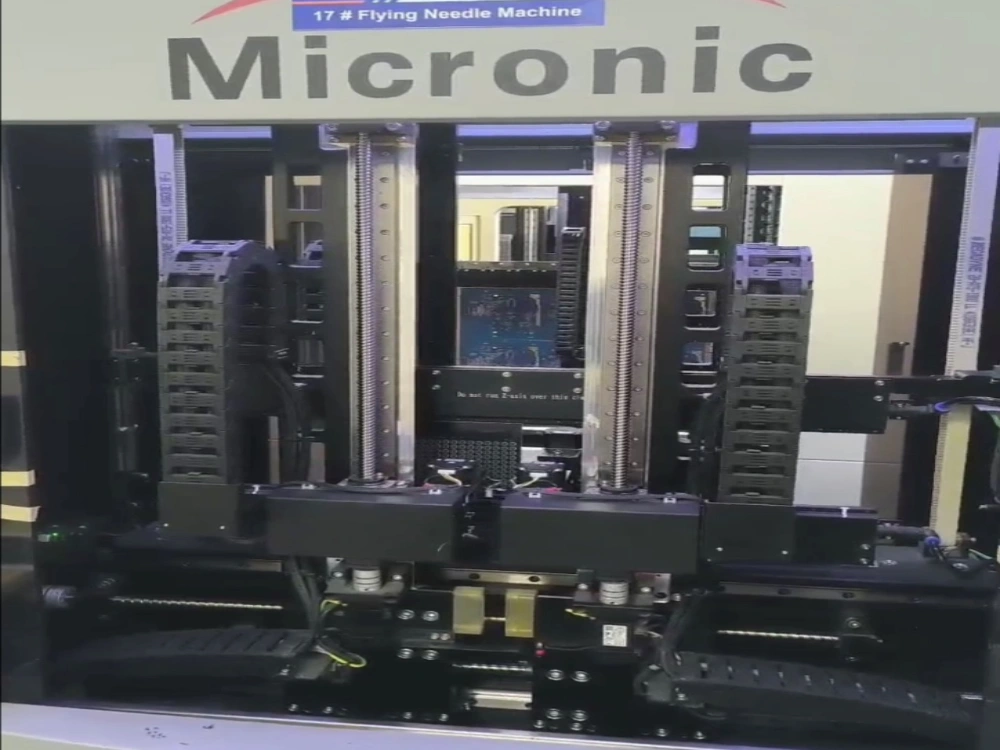

We apply a surface finish such as HASL, OSP, ENIG,etc, to protect the exposed copper and ensure solderability. - 12) Flying Probe Test:

A flying probe tests the PCB to check for electrical connectivity and ensure the circuit’s functionality.

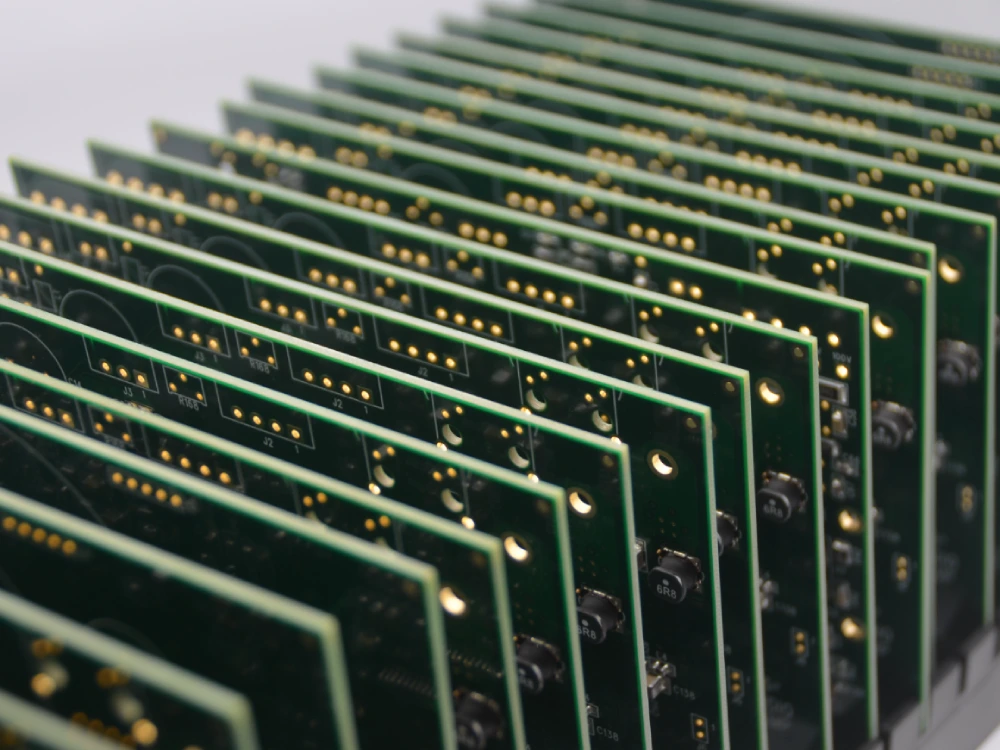

What To Pay Attention To When Buying Single-Sided PCB In Bulk

It’s better to buy single-sided printed circuit boards in bulk. In addition to the PCB pricing and quality, it is critical to comprehend the seller’s after-sales service. Circuit board repair, on the other hand, is a newer repair sector. If there is a problem with the electrical device’s single-sided PCB, replacing the circuit board will be more expensive. However, the seller is generally allowed to fix these damaged circuit boards.

It’s cheap and faster than re-customizing a single-sided circuit board. When ordering a lot of single-sided circuit boards, ask the buyer about after-sales service. A lot of people have reservations about repairing single-sided circuit boards. The materials and composition of various circuit boards differ. Each circuit board has integrated blocks, resistors, capacitors, and other devices. As a result, damage to one or more components might harm the entire circuit board. As a result, before making a purchase, please inquire about the seller’s sales service.

How To Choose A Single Sided PCBs

In the electronic industry, single-sided printed circuit boards are a remarkable technology. Now, the degree of automation of industrial equipment is increasing. As a result, the use of single-sided circuit boards is growing. Many businesses now produce single-sided printed circuit boards. So, how can we choose high-quality, low-cost, single-sided circuit boards from a sea of single-sided ones?

Single-sided printed circuit boards are common parts for most buyers. As a result, before purchasing, we must examine several factors. Almost every circuit board manufacturer produces single-sided circuit boards. On the market, there are several materials for single-sided circuit boards. This is one of the factors we must take into account.

In brief, if you wish to utilize electronic gadgets for an extended time. Then, selecting the proper single-sided circuit board would be beneficial. When choosing single-sided circuit boards, pay careful attention to insulation. Long-term air exposure will cause the single-sided circuit board to deteriorate slowly. Thus, the material of the single-sided circuit board must be well insulated.

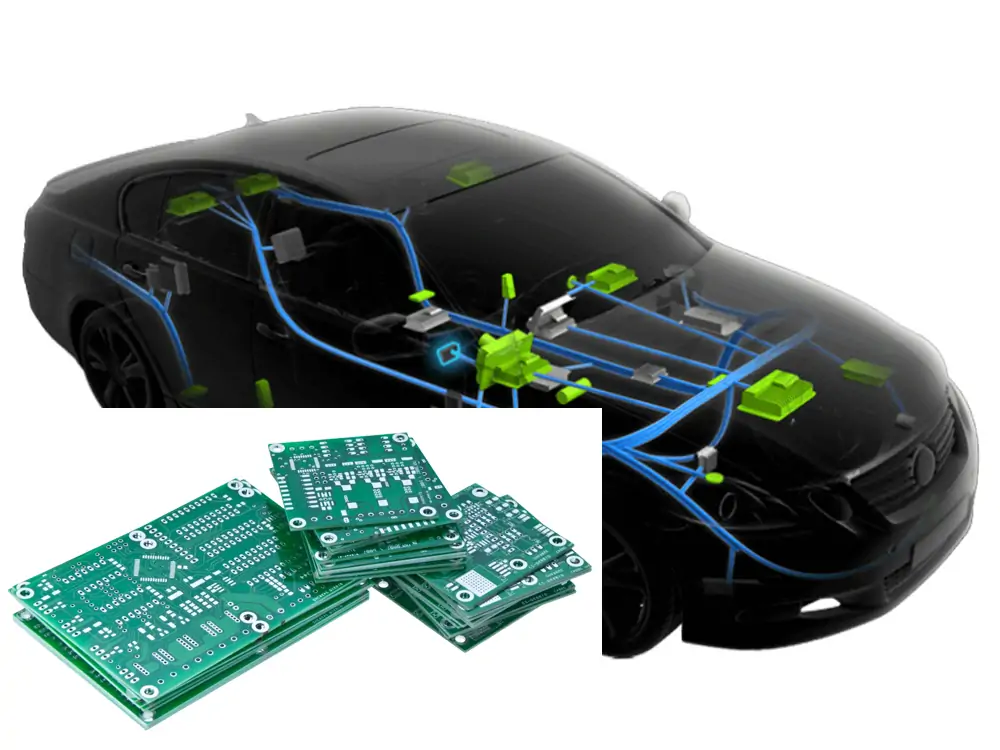

Application of Single Sided PCBs

With the advancement of society, the increase of PCB in electronic products has also increased. Circuit boards are an essential part of the electronics industry. Every electronic device needs a circuit board.

Single sided PCBs are popular in many applications. The application ranges from watches & computers to electronic communication equipment.

- Vending machines

- Camera systems

- Surveillance

- Calculators

- Sensor products

- Printers

- Solid-state drives

- LED lighting

- Power supplies

- Relays

We’re Here To Help You

Any questions? Contact us anytime, and we’ll respond to your inquiries within 24 hours.