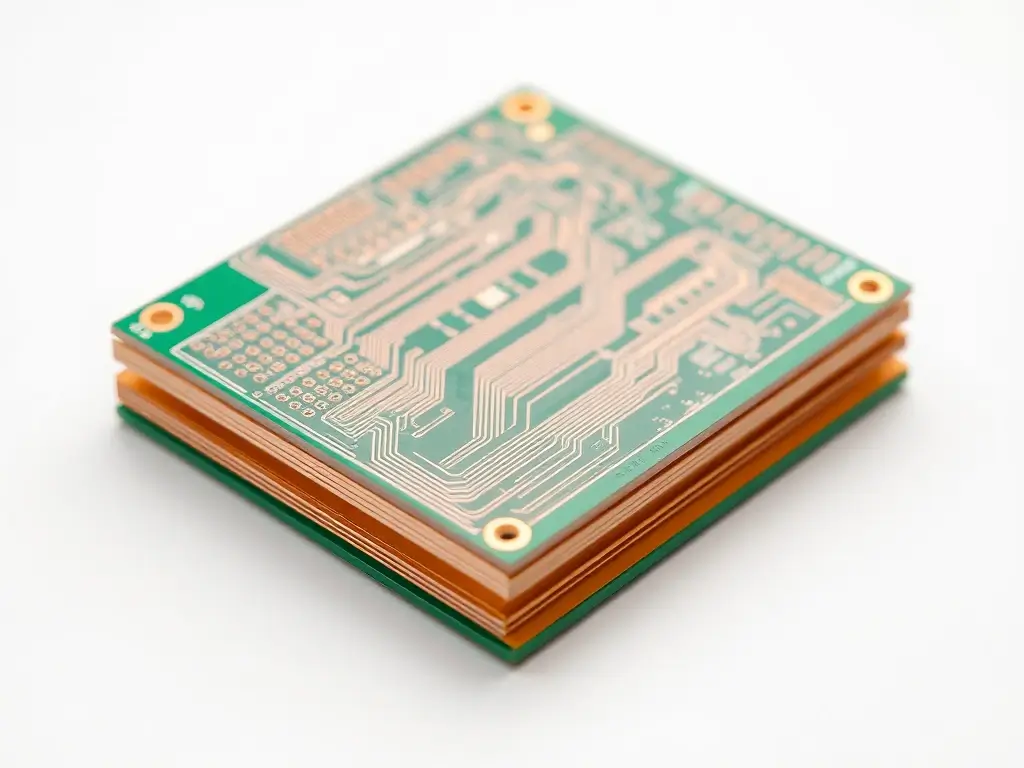

Thick Copper PCB Guide

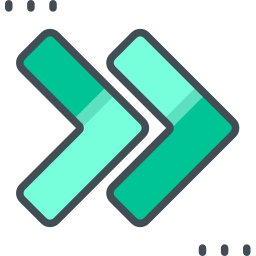

Thick copper PCB refers to a printed circuit board with a copper foil thickness greater than 3 ounces (3oz). 1 ounce is approximately equal to 35 microns. This special PCB design can meet the needs of high current and high power.

Compared with standard PCBs, thick copper PCBs can carry higher currents.

- 3oz copper foil can carry a current of about 12A

- 6oz copper foil can carry a current of about 20A

- 10oz and above can carry a higher current

Technical Specifications Table for Thick Copper PCB

| Parameter Category | Technical Parameter | Specification Range |

|---|---|---|

| Copper Thickness | Standard Thickness | 3oz-20oz (105μm-700μm) |

| Inner Layer | 1oz-12oz (35μm-420μm) | |

| Outer Layer | 3oz-20oz (105μm-700μm) | |

| Board Parameters | Material Type | FR-4, High Tg Material (Tg 150-180℃) |

| Board Thickness | 0.4mm-5.0mm | |

| Layer Count | 1-16 layers | |

| Design Parameters | Minimum Line Width | 3oz: 8mil |

| 6oz: 12mil | ||

| 10oz: 16mil | ||

| Minimum Spacing | 3oz: 8mil | |

| 6oz: 12mil | ||

| 10oz: 16mil | ||

| Minimum Hole Size | 0.3mm (finished hole) | |

| Board Dimensions | Max 650mm × 550mm | |

| Surface Finish | Available Options | HASL(Lead-free) |

| ENIG | ||

| OSP | ||

| Immersion Gold | ||

| Immersion Tin | ||

| Electrical Properties | Withstanding Voltage | ≥3000V |

| Insulation Resistance | ≥10^4 MΩ | |

| Maximum Current Density | 35A/mm² | |

| Reliability Indicators | Soldering Heat Resistance | 288℃, 10s |

| Peel Strength | ≥1.4N/mm | |

| Temperature Resistance | -65℃ ~ +125℃ | |

| Via Reliability | Meet IPC Standards | |

| Special Requirements | Impedance Control | ±10% |

| Bending Performance | Meet IPC-6012 Standard | |

| Board Flatness | ≤0.7% |

Notes:

- Parameters may be adjusted according to customer requirements

- Special specifications need advance confirmation

- All parameters comply with IPC standards

- Customized solutions available

Advantages of Thick Copper PCB

- High Current Capacity

- Handles larger current loads

- Suitable for high-power applications

- Reduces circuit overheating risks

- Superior Heat Dissipation

- Better thermal conductivity

- Efficient heat spreading

- Lower operating temperature

Special etching process is used to ensure circuit accuracy.

Multi-layer lamination technology ensures inter-layer bonding strength.

Advanced surface treatment improves welding performance.

Strict quality control ensures product reliability.

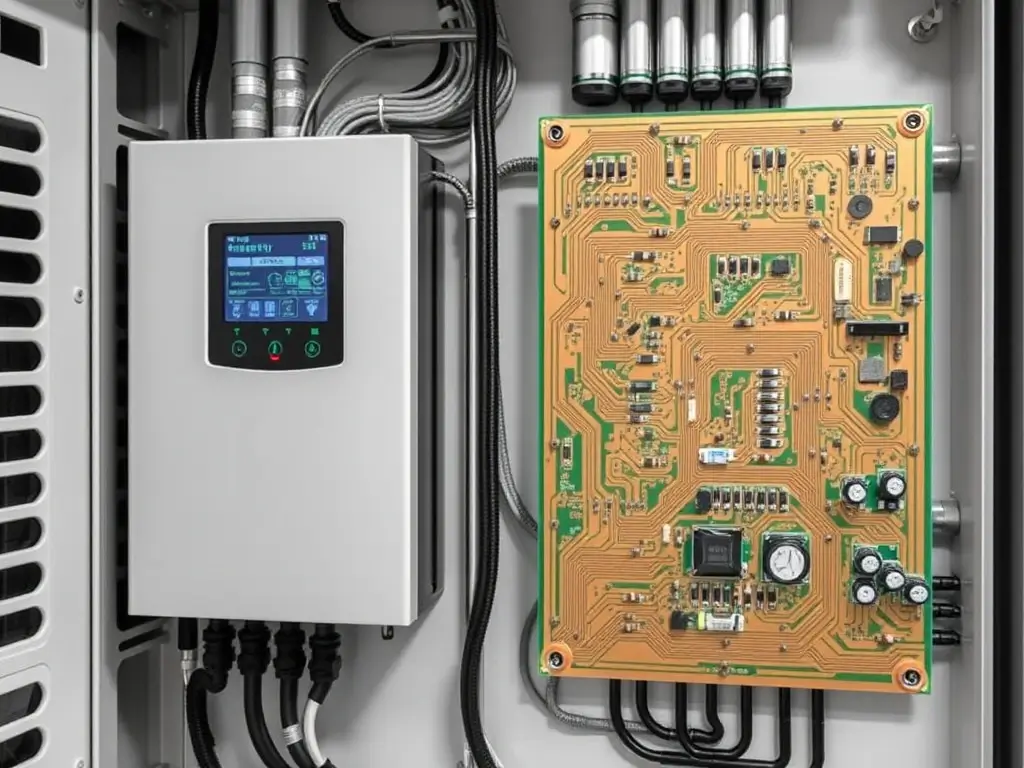

Applications of Thick Copper PCB

Power Supplies

Thick Copper PCBs are used in power supplies for their ability to handle high currents and dissipate heat efficiently.

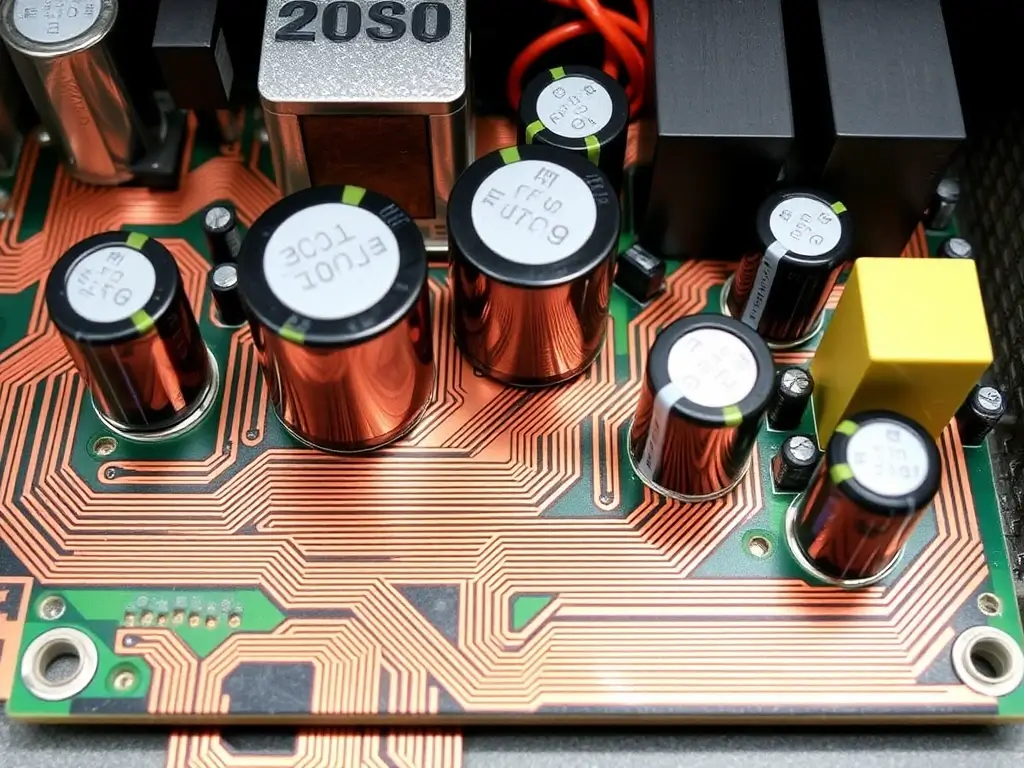

Electric Vehicle (EV) Charging Stations

- High current handling capability

- Reliable power distribution

- Enhanced safety features

Industrial Power Supplies

- Stable power output

- Excellent heat dissipation

- Heavy-duty performance

Solar Power Inverters

- High power conversion efficiency

- Thermal stability

- Weather-resistant design

Aerospace Applications

- High reliability power distribution

- Radiation-resistant design

- Thermal cycling tolerance

Telecommunications

- High-frequency signal handling

- Power amplification modules

- Thermal management systems

We’re Here To Help You

To better understand our products and services, feel free to contact our customer service team at any time. We look forward to establishing contact with you, solving your needs, and creating wonderful cooperation opportunities together!