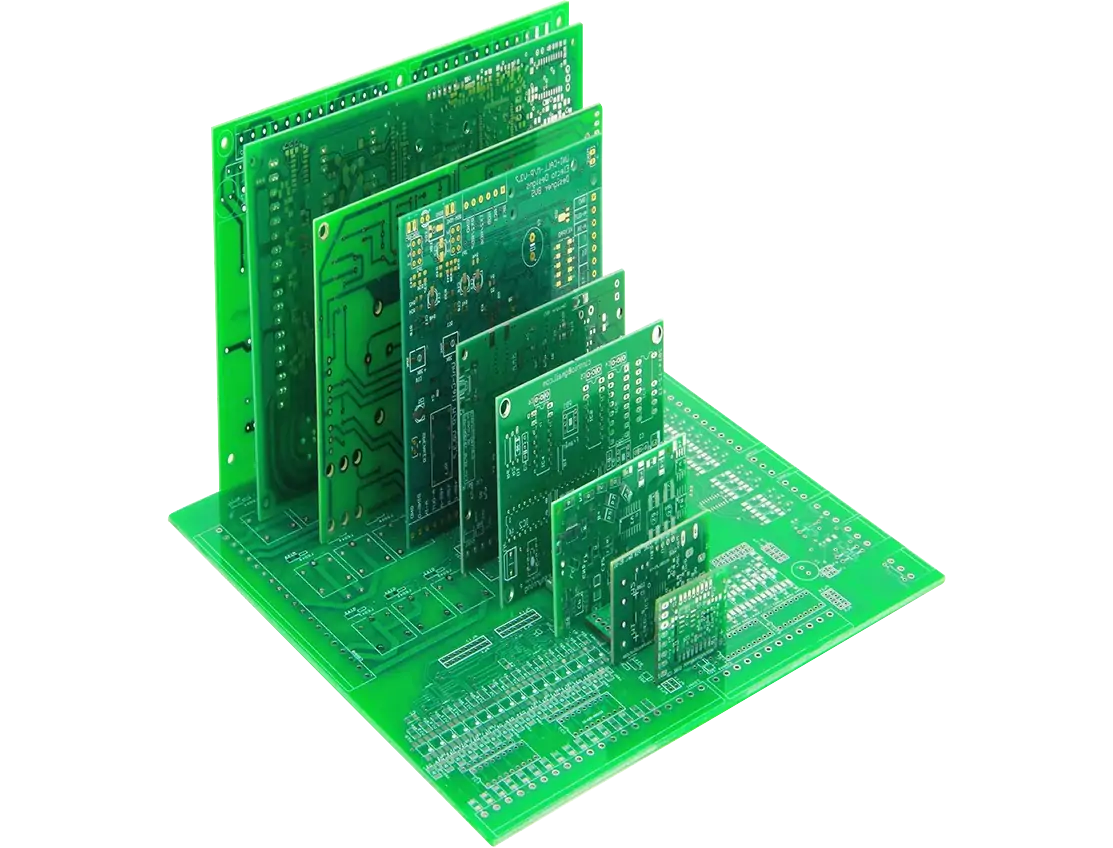

Pcb prototype service introduction

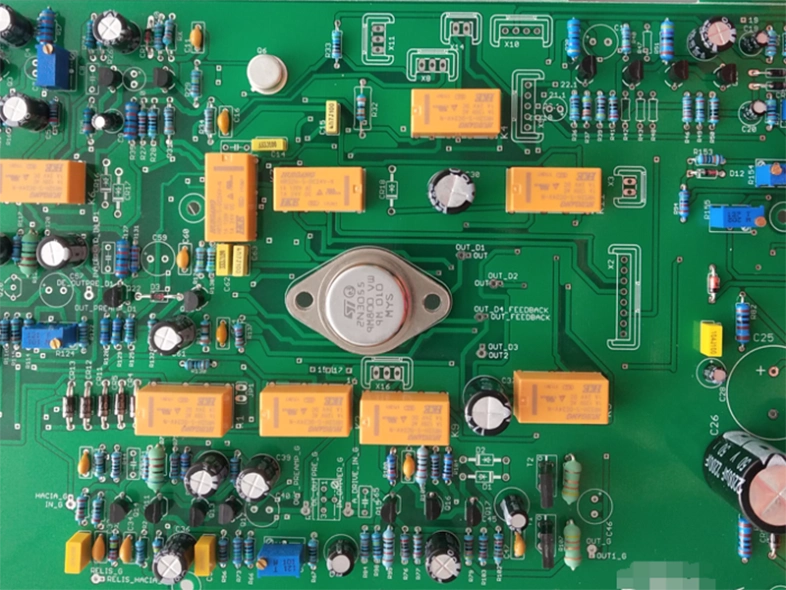

Component assembly

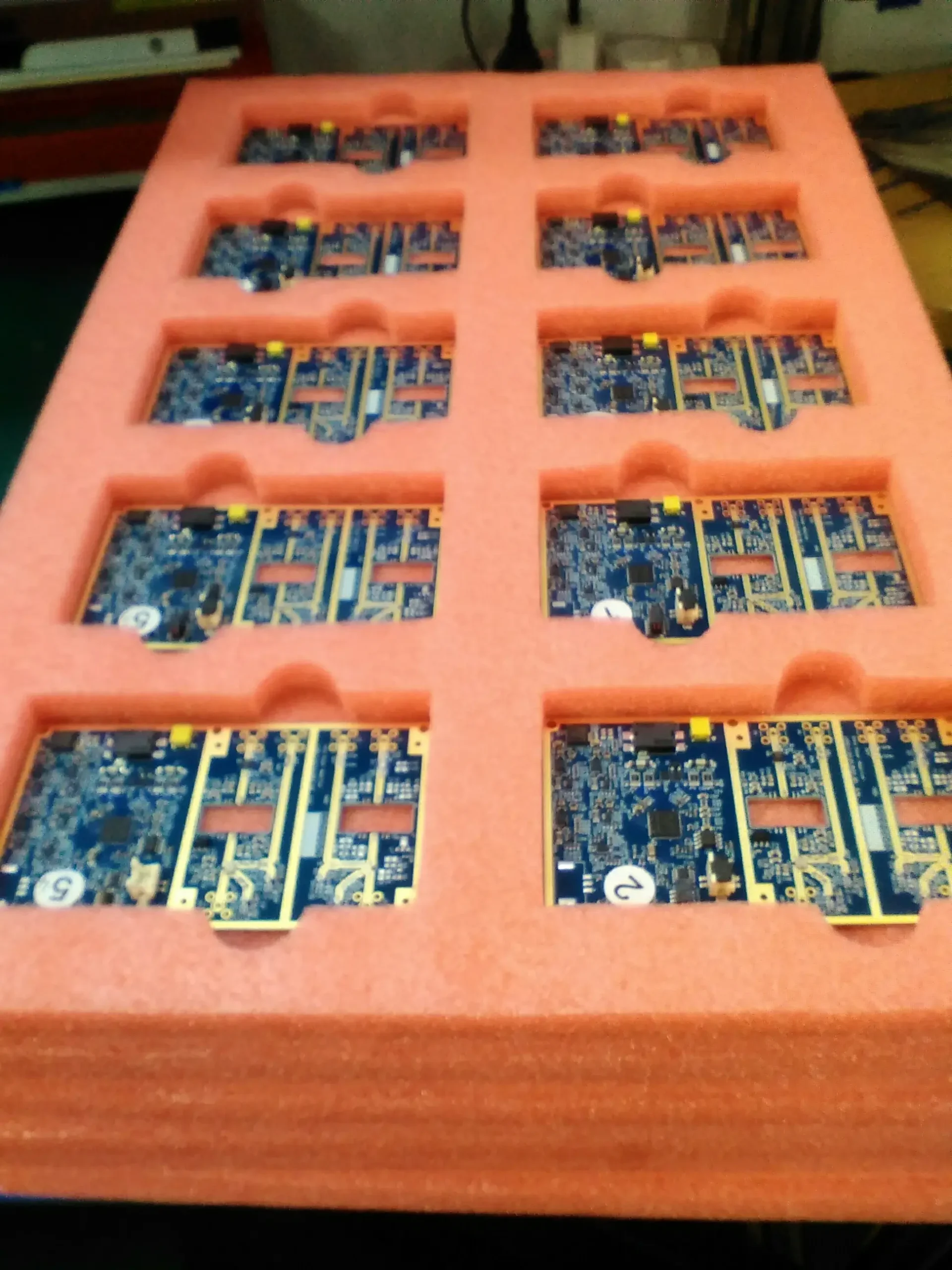

| Feature | Through-Hole | SMT (Surface Mount Technology) |

|---|---|---|

| Component Type | Long-leaded, larger components (e.g., electrolytic capacitors, transformers) | Compact, leadless components (e.g., SMD resistors, ICs) |

| PCB Design | Requires drilled holes (common for single/double-layer boards) | No drilling needed (ideal for high-density multilayer boards) |

| Mechanical Strength | High (suitable for physical stress or high-temperature environments) | Lower (relies on solder paste adhesion) |

| Cost/Efficiency | Higher labor costs (ideal for prototypes/low-volume) | Highly automated (optimized for mass production) |

Manual and automated Insertion

Lead-free or RoHS soldering

Double Wave Flow Solder

Selective wave soldering

Use low and high melting point solder

Conformal Coating

IC Programming

Inspection and functional testing

UETPCB is a professional pcb supplier & pcba manufacturer in Shenzhen. We focus on providing high-quality PCB assembly services. As a reliable PCB supplier, we provide one-stop service from PCB manufacturing to assembly. Our professional team has the experience and skills to meet the needs of various industries. Our goal is to be your preferred partner in China PCBA manufactory. If you need quality PCB assembly services, please contact us.

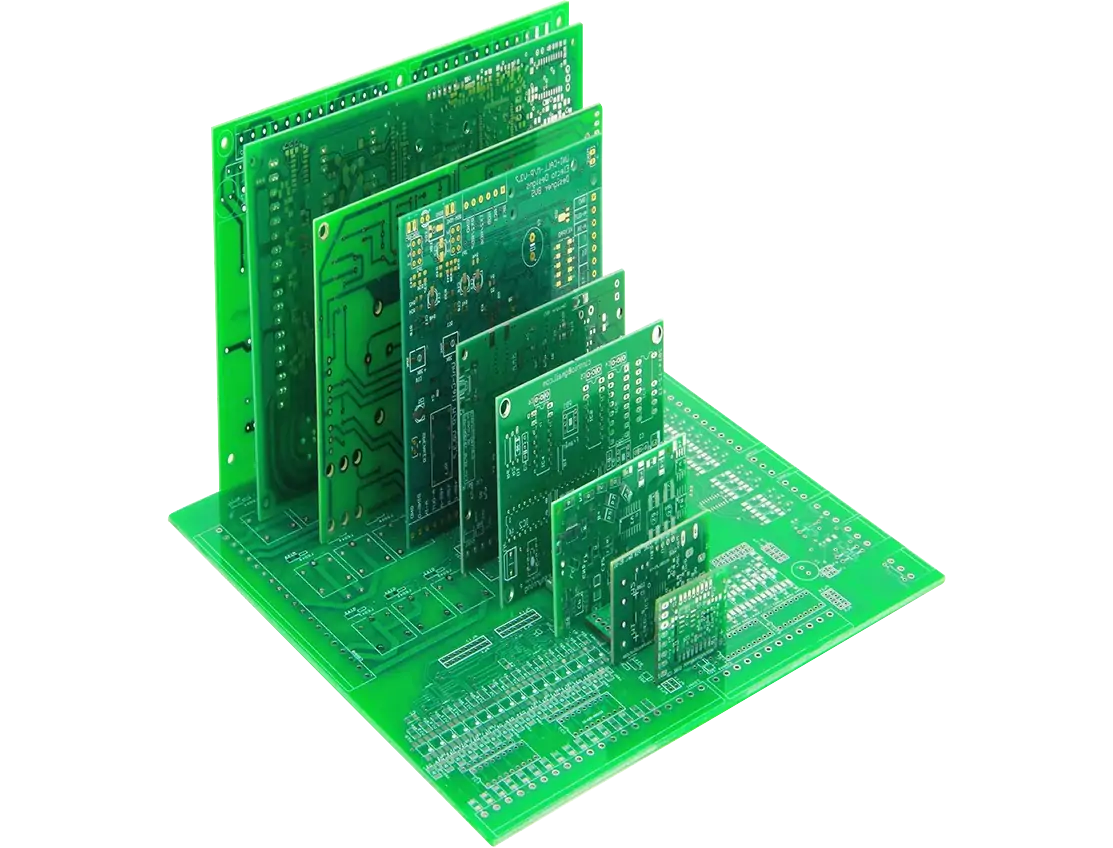

Step 1:Creating a designed layout on the copper-clad laminate

Step 2:PCB manufacturers will etch or remove excess material from inner layers to reveal images and pads.

Step 3:Laminating printed circuit board materials at high temperatures for creating the PCB layer stack up

Step 4:Creating mounting holes, through-hole pins, and vias on PCB

Step 5:Etching and removing the excess copper of the surface layer to reveal images and pads

Step 6:Placing plating pin holes and via holes

Step 7:Creating a protective coating or solder masking on the surface

Step 7:Silkscreen printing, logos or other markings, and installing polarity indicators on the surface

Any questions? Contact us anytime, and we’ll respond to your inquiries within 24 hours.

We specialize in building your pcb prototype and PCB assembly with rapid turn times.