The electronics market is growing rapidly. PCB Assembly Manufacturers are coming up with new ideas and features to be more competitive in this market.

You know PCBs are the heart or brain of every electronic device. Therefore, the more precise the assembly, the more durability you can ensure. Most electronic manufacturers are focusing on this sector.

It is essential to keep in mind that not all companies that make PCB assemblies can provide cutting-edge options. For prototyping to work, you need skilled knowledge and advanced manufacturing skills. However, UETPCB has numerous special features and offers a wide range of options during the manufacturing process.

What are the most essential concerns to consider when making these PCBs? The primary steps are quality, affordability, lead time, and delivery. Additionally, consider utilizing prototyping services. These steps will surely help you.

You might be looking for a one-stop solution. Typically, you want to avoid troubles and complex processes. From sample creation to delivery, all you want is the most flexible solution. Among the various factors, you must check the factory’s assembly services. Does it provide turnkey assembly services? Are there any processes for end-to-end solutions? Additionally, what are their production capabilities?

You should also consider their professional skills, the level of service they provide, and their stability. The following discussion can help you choose the best maker. This guide will tell you everything you need to know about it.

What is the difference between PCB manufacturers and PCB assembly Manufacturers?

There is a slight difference between PCB manufacturing and PCB assembly manufacturing. PCB manufacturing refers to the process of creating printed circuit boards (PCBs). On the other hand, PCB assembly is adding traces, ICs, or other accessories to the board. Below, you will learn how both systems work.

PCB manufacturers

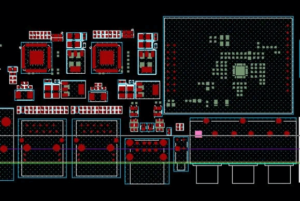

PCB manufacturers are the companies that produce printed circuit boards. If you pay closer attention to a PCB board, you will find it is stacked up with multiple layers. Each of these layers has different functionalities.

When making PCBs, manufacturers must follow all the proper steps. In design and production, new technologies are utilized to achieve better results.

PCB manufacturing includes setting the board type, stacking layers, trace width, and PTH. Additionally, there are other concerns during the manufacturing process.

PCB assembly manufacturers

PCB board assembly manufacturing involves mounting integrated circuits (ICs), capacitors, resistors, and other electronic components. Typically, it indicates the placement of electrical components. For optimal performance, use the most effective equipment compatible with this circuit board.

PCBA primarily focuses on improving the installation of components. In this case, surface mount technology (SMT) and through-hole technology (THT) are two critical steps.

Besides, PCBA also focuses on testing and certifications of the final PCB. These PCBs are used in different circumstances.

How to Check the Capabilities of a PCB Assembly Manufacturer

Most newcomers in the PCB market make mistakes when choosing the proper PCB assembly manufacturer. The leading cause of this failure is failing to check their capabilities. In the following few sections, you will learn a few points that can help you in this case.

#1 Design for Manufacturability (DFM) Support

DFM is the most critical aspect of the PCB manufacturing process. It involves concept improvement, design optimization, and prototype testing. Additionally, DFM includes system integration and finalizing the design. It’s almost a multipurpose service. DFM ensures the final review of your design to identify errors or mistakes that could cause future problems.

So, a competent DFM helps you save time, avoid blunders, and results in lower costs. A professional manufacturer always ensures they have proper DFM checking processes. You must choose a manufacturer who provides it professionally.

#2 Ability to Deal with Different Types and Layers of PCB

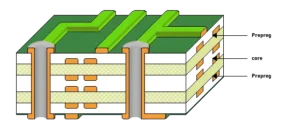

A manufacturer should be capable of handling various types of PCBs and layer counts. There are several types of PCBs. For example, PCBs can be single-sided, double-sided, or multi-layered. Special kinds of PCBs include HDI, flexible, rigid, rigid-flex, and others. Each PCB has a different structure and shape. Moreover, the use of these PCBs varies depending on the device’s operations.

According to your requirements, the maker must ensure each board meets a specific size. Moreover, they should be overseeing layer alignment, links, and other signal-related tasks. Thus, you can provide a fine working PCB as needed.

#3 Prototyping and Low-Volume Production

A reliable PCB assembly manufacturer should offer prototyping and low-volume production. Prototyping is a significant part of it. It allows you to review the final design for the next step. To make it easier, you can categorize it as “works-like,” “looks-like,” and “test-like.” If you find any mistakes, the expert team must solve them instantly. This feature enables you to fix such issues before full production.

They should also handle small orders with meticulous care. This approach demonstrates your commitment to quality in every order.

#4 High Volume Production Capabilities

High-volume PCB assembly manufacturers are the most chosen ones worldwide. If you want to order in small batches, you should opt for them to get better outcomes. There are other benefits of choosing them as well.

Selecting them allows you to order thousands of PCBs simultaneously. Additionally, they utilize exact machines to manufacture these PCBs. That’s why the system is suitable for large businesses and mass-market products. Besides, mass production helps you reduce costs as well. So, you should select accordingly.

#5 Production Lead Time

Lead time refers to the time elapsed from the production of printed circuit boards (PCBs) to their delivery. Fast turnaround plays a key role here. It encompasses the whole manufacturing process. A trustworthy manufacturer should offer a short lead time for production. Quick turnaround with high quality is another reason to select them. Most clients fall for this flexibility.

Lead time covers raw material selection, assembly, delivery, transportation, and other processes. To cover the whole process, you must complete all steps on time to meet the deadline. So, it increases the reliability and confidence of every client.

#6 Component Sourcing and Supply Chain Management

Component sourcing and supply chain management are both important topics. The company should have reliable suppliers for parts sourcing. The customer may need rare parts for PCBs. So, they should handle hard-to-find, old, or custom-designed parts. This will help you run your PCBs smoothly. Besides, it allows you to move production easily.

On the other hand, supply chain management encompasses logistics, inventory management, and planning. It also involves safe return management. When selecting a manufacturer, ensure that you confirm these two key factors. It will benefit you along the way.

#7 Automated Assembly Capabilities

It shows PCB Assembly Manufacturers employ advanced machines to make PCBs. Pick-and-place, reflow, and soldering are some of these methods. In this case, technology helps to expedite the process while maintaining accuracy. They can easily bring out smooth results and minimize human errors.

Automated machines are more capable of handling tiny items. For example, they can work on 01005, BGA, and QFN. Overall, they produce quick and accurate outcomes for both small and large production. For this reason, these machines are in high demand nowadays.

#8 Testing and Quality Control

The last and most important part is to verify testing and quality compliance. The type of testing and quality work the company provides is crucial. They should have Automated Optical Inspection (AOI), X-ray, or other functional testing. It allows you to evaluate the product for defects or deviations.

The company must adhere to international standards for quality assurance. There are various types of quality certifications for this. The company should have these certificates. Examples are ISO, IATF, RoHS, UL, and others. By considering them, you will be able to choose your desired makers. By considering them, you will be able to select your desired maker.

What are the Benefits of analyzing the capabilities of a PCB Assembly manufacturer?

There are four reasons why you should look into what a PCB assembly company can do. The primary goal is to mitigate the risks associated with your investment. By examining what they can do, you can determine what the maker intended to do. This way, you’ll be aware of better products and potential delays. In this way, you lower the chances of having to make fixes or wait.

Cutting down on costs is the second benefit. You can avoid making mistakes and get good results if you know what the maker can do. This way, you can reduce unnecessary costs.

The third one is better control of quality. When you know what a company can do, you know what they’re good at. You can predict the outcome of your goods. You can also review some of their examples and visit their factory to gain a deeper understanding of their products.

The last benefit is ensuring the standard of the product. When you know more about a maker, you can better understand the standards that their work adheres to. Do they have extensive knowledge of foreign standards, such as IPC, ISO, or RoHS? This way, you can ensure your PCBs meet the highest quality standards.

Are You Looking for the Right PCB Assembly Manufacturers?

After all these findings, you now know how to select a reliable PCB Assembly manufacturer. UETPCB is one of the most popular PCB assembly manufacturers in China. They offer a comprehensive range of services, including prototyping, turnkey assembly, and delivery. UETPCB is a comprehensive, all-in-one service provider. They are highly compatible with ISO, IATF, CE, and UL certifications.

So, what is holding you up? Start your new project today with UETPCB for a better experience. For further queries, don’t hesitate to contact us. We provide a 24/7 Q&A service.