A flexible PCB is a popular type of Printed Circuit Board. As the name suggests, these PCBs are bendable. You can literally twist or fold it during use.

Most people may be confused about the concept of rigid and flexible PCBs. First, the materials for both are different. FR4 or other rigid materials are used in rigid PCBs, while flex PCBs use polyimide or PET. Second, rigid PCBs are not bendable, while flex PCBs are easily bendable. Third, flex PCBs are lightweight and ideal for any electronic gadgets. Conversely, rigid PCBs are suitable for many stationary gadgets.

Flexible PCBs offer several advantages. These benefits primarily make them suitable for a wide range of applications.

- Flexible PCBs can save a lot of space. They can be used for electric gadgets that have tight space requirements.

- These PCBs are lighter than rigid PCBs.

- These PCBs are durable. Technically, durability depends on the stiffening material used in the flexible PCB fabrication method.

Flexible PCB Manufacturing

Because of COVID-19, the PCB market worldwide was reduced in 2023. But from 2024, it began to grow at 6.3%, according to the Taiwan Printed Circuit Association and ITRI. This comes after a steep 15.6% decline last year, with a loss of $73b. Therefore, experts expect this market to become stronger and more stable in the coming year.

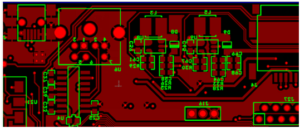

Flexible PCB fabrication usually has several steps. Each step is very crucial for high-quality flexible PCB manufacturing.

Step #1 Flexible PCB design

The first step in flexible PCB manufacturing is designing the PCB. First, what’s the concept of your design? Next, know the requirements. Then, prepare a schematic and design the layout. Finally, carefully observe the simulation result and prepare a Gerber file for later steps. The whole process typically ensures the design is ready for production.

Step #2 Material Selection

Once your design is ready, the next big step is choosing the suitable material. There are three major types of materials: polyimide PET and high-frequency material. Thus, always select the one preferable for your project. Next, carefully determine the appropriate thickness of the copper foil. Adhesives are also central to thought here.

Other requirements, such as surface finishes, are also necessary. There are three major types of surface finishes: ENIG, HASL, or OSP. Choose the most appropriate one according to the project requirements you are working on.

Step#3 Material Preparation

After that, gather everything you will need for particular flexible PCB production. This stage mainly covers the following operations: cutting, cleaning, and pre-treatment.

Step #4 Flexible PCB Printing

You can start flexible PCB printing once you have a plan and the needed materials. This step also has a few crucial steps.

Each flexible PCB manufacturer generally has its own production rules. However, UETPCB always ensures high-quality flexible PCB printing in this case.

Step #5 Placing Components

Carefully place components on the PCB. First, select the correct components based on the design specs. Always check for compatibility and availability. You can now use automated machines or manual methods to place these components.

Another critical step is soldering. You can solder in several ways, such as by hand, with reflow, wave, or other methods. You can pick the correct method based on your production volume and quality. Lastly, make sure that all of the parts are lined up correctly.

Step #6 Attaching Stiffener

The final step is attaching a stiffener. Note that the stiffener is not part of the PCB system. It just gives the PCB mechanical strength. A stiffener is very important for a flex PCB.

Select an appropriate stiffener material. In this case, FR4 or steel is the most commonly used stiffener. Gently place the stiffener on the specified location. Then, it is bonded securely using adhesive or thermal bonding with pressure and heat. Finally, test for any issues and resolve them if necessary.

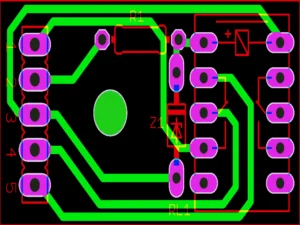

Custom Flexible PCB Fabrication: Flexible PCB Design Rules

As you know, flex PCBs are bendable and perfect for many uses. They are often found in smartphones, computers, and other gadgets. We have already seen those uses in the previous sections.

This part is mainly for people who want to learn about flexible PCB design rules. Also, the subject is crucial in making bendable PCBs.

Following these rules can get you the best performance. Most importantly, these rules prevent many problems from happening. If you decide to do batch production, they help you save money. Overall, you must follow these rules to get the best quality PCBs.

#1 Board Type

For the first parameter, you should choose the appropriate type of board. In this case, you have three options: single piece, panel by you, and panel by the flexible PCB manufacturer. If you choose the second option, you can define your panel layout. However, if you select the third option, the flexible PCB manufacturer will decide based on your design.

You may be familiar with PCB array, another name for PCB panels. It is actually a crucial term in flexible PCB manufacturing. A PCB panel is a group of PCBs that are put together to make one larger panel. Single-panel PCB manufacturing is generally costlier than other methods.

#2 Number of Designs in Flex PCB Panel

Multiple designs on a single PCB panel can speed up production. The more designs there are, the faster production will be, eventually reducing overall cost. The manufacturer will need this information to create a quote when designing your flex PCB.

#3 Flexible circuit PCB Size Dimensions

Next, you must specify the dimensions of your flex PCB. Every flexible PCB manufacturer has some standard shapes and sizes. You can select any of those based on your needs.

As you know, PCB size generally affects the design complexities. In this case, you can ask for professional assistance or contact our customer support team. UETPCB always offers complete solutions. From design to manufacturing, this is a one-stop shop for everything.

#4 Number of Layers in Flexible PCB Board

A single-layer PCB is usually basic and often affordable but also versatile. However, this flex PCB is ordinarily unsuitable for high-speed operation or work. For a more advanced option, it’s evident that you have to go for multi-layer PCBs. While multi-layer PCBs are somewhat costly, they are well-suited for most compact PCBs.

#5 Type of Base Material

Next, wisely choose a suitable base material for your flexible circuit PCB. There are three main options: polyimide, PET, and high-frequency materials.

Polyimide is typically more flexible and very stable at high temperatures. But if you want something cheaper, choose PET. Finally, Materials with a high frequency can generally work well at high speeds.

#6 Flexible PCB board thickness

The thickness of your flex PCB must be balanced. As you know, thinner boards are usually more flexible but may be less durable. In most cases, flexible PCB design thickness ranges from 0.025mm to 1.0mm.

#7 Track size & Spacing

Flex PCBs can bend if necessary; the track size and spacing matter greatly. The correct design can prevent electrical shorts. Overall, you can enjoy a reliable performance.

#8 Solder Mask

Solder masks generally protect copper traces so they don’t corrode. They come in various colors and materials. During assembly, solder masks also help in preventing solder bridges. As a result, you can create different levels of protection.

Solder bridges are one of the most common types of PCB manufacturing issues. They happen when excess solder connects two or more pads, creating an unwanted bridge. Eventually, this leads to short circuits and, finally, system malfunction.

#9 Edge Connector

Edge connectors are mainly used to interface the flex PCB with other components or systems. So, your flexible PCB design must ensure secure and reliable connections. In this case, you can also consider mechanical stress and repeated use.

#10 Flex PCB Surface Finish

The next factor you must consider is the surface finish. The better the surface finish is, the better the solderability. There are several options there. However, HASL, OSP, and ENIG are the most common. HASL is a cost-effective method, while ENIG offers more surface planarity. Finally, OSP allows you to fine-pitch applications.

#11 Other Rules

Other rules, like the thickness of immersion gold, finished copper, and tape, are also noteworthy. Although the above parameters are the most common, consider the minor rules as well. We recommend you consult all these with a professional. You can also reach out to our customer support team.

Summary

Let’s wrap everything up! As the name suggests, Flex PCBs are mainly made of flexible material. You can fold and spindle them; they won’t break. They are usually quite flexible in serving numerous electronic designs. Of course, it can be versatile in several shapes and dimensions.

Flexible PCB manufacturing generally has a few steps. As you can see from the above diagram, it starts with design and ends with quality testing. Note that every step is critical to maintaining the highest quality. At UEPCB, your trusted, flexible PCB manufacturer, we always ensure all these parameters are met.

Flexible PCB design rules mainly focus on every spec of a PCB board. This topic includes the number of panels, layout, design, PCB thickness, and materials. Carefully assess these terms when you look for a batch production.

If you have any questions, contact our customer support team.