PCB (Printed Circuit Board) is the backbone of almost every electronic device. From smartphones to high-end gadgets, these boards have their roles. The FR4 material is generally used in the making of these PCBs. But the question is: what is FR4 material? Many people seem to have no basic know-how about this material and its properties.

In fact, it is a myth that FR4 itself is a PCB type, which is wrong. It is a flame-retardant material that is known for its strength and durability. It is used in PCB fabrication due to its multiple favourable properties. In this article, we will discuss FR4 material and explain why it is preferred for making PCBs. So, let’s begin.

What Does FR4 Mean?

“F” and “R” in FR4 material stand for flame and retardant, respectively. The digit 4 in FR4 refers to the grade designation. This number is given by NEMA (National Electrical Manufacturers Association). It is flame-retardant and resists when exposed to high temperatures. It does not catch fire quickly, making it a popular option for use in PCBs.

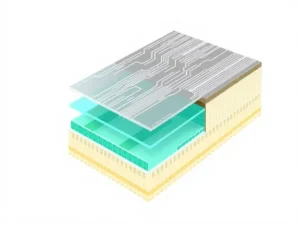

FR4 material grade is made of high-quality fiberglass cloth reinforcement with epoxy resin. The reinforced fiberglass gives this material strength and durability. This material has excellent electrical insulation. However, its flame retardancy is considered a significant advantage.

Apart from being flame-retardant, FR4 material has many other valuable properties. Those include better electric insulation, moisture resistance, and above all, lower pricing. Therefore, its usage has become more prevalent than ever before. Its electrical insulation is something that is widespread in PCBs and other electronic devices.

The epoxy layer offers excellent insulation. It prevents the electric current from flowing in areas where it should not move. In this way, the current only flows through the dedicated copper lines. This layer prevents electrical shorts on the PCBs and other devices. As you know, all electronic devices use PCBs (Printed Circuit Boards).

If a short circuit happens in the PCB, all the other components present on it would fail. Therefore, manufacturers use FR4 material in making PCBs. Remember, this material is also moisture-resistant and can be used in extreme moist conditions. Even exposure to high humidity does not cause any issues in their performance.

Why is FR4 Material Used in PCB Fabrication?

PCB is the frame or skeleton used in an electronics device. This frame consists of many key components in these devices. Those components include resistors, chips, capacitors, and the list goes on. All the components present on the boards are connected through copper wires.

If this board is weaker, it can affect the overall quality and performance of electronic devices. Right? Therefore, FR4 is used in making PCBs. It ensures better strength, durability, and overall performance of PCBs. There are multiple reasons for using FR4 material in PCBs. In the section below, we will explore all the potential reasons:

1- Electric Insulations

As I said earlier, PCBs are frames that contain many small components. The copper lines or wires are used to connect those components. The electrical current or signal flows in these copper lines to power devices. The FR4 material is non-conductive.

It offers electrical insulation, thanks to its stable FR4 dielectric constant. It does not interfere with electrical signals. As a result, current or signal flows in the copper lines without leaking. This results in the reliable performance of PCBs in electrical devices. This is the primary reason behind the active usage of FR4 material in making PCBs.

2- Flame or Heat Resistance

FR itself stands for Flame Retardant. Right? This is the primary reason for this material being used in the fabrication of PCBs. Remember, the electrical components present on PCBs release heat while they’re working.

This heat can cause the melting and deterioration of the PCBs. However, the usage of FR4 material in PCBs increases the fire resistance of PCBs. You’ll notice that modern devices keep running for many hours without getting damaged. The credit behind this consistent performance goes to the FR4 material used in PCBs.

3- Low Moisture Absorption

One of the prominent features of FR4 material is its low moisture absorption. So this material remains dry and does not attract moisture from the surroundings. These properties ensure that PCBs remain dry even in highly moist conditions. Not only is FR4 material low in absorption, but it is also weather-resistant.

This material is reinforced with fiberglass cloth and epoxy resin. These materials make the FR4 very dense and give it excellent sealing. So moisture and water splashes do not go inside, which could cause corrosion issues. This makes components and copper lines present on PCBs safe from rusting and deterioration.

4- Rigid & Durable

FR4 PCBs are known for their exceptional strength and durability. As I said earlier, the FR4 material consists of reinforced fiberglass and epoxy resin. The reinforced fiberglass gives excellent structural strength to this material.

So, it becomes excellent at withstanding stress and harsh usage. When used in PCBs, it ensures that the PCB does not crack or deform due to its rigidity. Additionally, this material prevents moisture from affecting the quality of the PCB. Due to this, the PCB becomes more durable and long-lasting. It can withstand harsh usage with ease.

5- Affordable Pricing

There are different types of materials available for use in PCBs. However, some of them are very costly. On the flip side, low-priced material comes with compromised properties and is not ideally durable. FR4 materials are both affordable and come with all the desired properties.

It is durable, stronger, moisture-resistant, and offers excellent electrical insulation. So, manufacturers use this material and make PCBs at a low price. This is a significant advantage as they can then sell their PCBs at an affordable rate and make a good profit. The affordable prices of FR4 material are the primary reason behind its usability in PCB fabrication.

Limitations of FR4 Materials for PCB Fabrications

Despite many advantages, FR4 materials also come with some limitations. Knowing these limitations is essential, especially if you’re in the PCB fabrication business. Here is their list:

- First of all, FR4 cannot withstand extreme temperatures. Its flame retardant should not be considered flameproof. If the components present on the PCB emit extreme heat, the FR4 material may fail to protect the PCBs. It is only suitable for moderate levels of heat.

- As I said earlier, the FR4 material is rigid and less flexible. This rigidity is helpful as it protects the PCB from cracking or breaking. However, in some cases, you may need a flexible design of the PCB, especially in compact electronic devices. In such a case, the rigidity of FR4 material won’t allow for making a flexible PCB design.

- Are you choosing a PCB for a device with a high-frequency circuit? If so, you should not use FR4 material in such a case. At high frequencies, FR4 can cause signal loss, interrupting the operation of components and devices. This material is only suitable for low to medium-range frequent circuits.

Conclusion

FR4 material is an excellent option for use in PCBs. What I love about this material is that it does not catch fire quickly. PCBs generally face the heat emitted by the component mounted on them. The use of FR4 material ensures that the PCB does not deteriorate due to heat. It remains stable and ensures that its components work fine. In this article, I’ve explained FR4 material and the reasons why FR4 is used in making PCBs.