Introduction:

Do you know the continuously growing technology that is Flexible PCB? This advanced technology is used in many electronic sectors, such as warehouses and telecommunication. The flexible PCB brings a revolution in the interconnection of electrical components. The primary function of a flexible PCB is to connect different parts in one circuit or connect to multiple devices.

Flex PCBs bring different advantages over rigid PCBs and carry weight, space, and cost solutions. So the connection made by the flexible pcb PCB is compact and flexible. Also, electrical connections can obtain high density.

What is a flexible circuit?

Flex circuits, also called flexible printed circuits, are more commonly known as printed circuit boards. The term “printed” describes objects such as photos or images. But the circuit draws a pattern, which is why the term print is used.

The flexible circuit is composed of layers of metallic layers that are bonded to a dielectric layer. The layer can be.0001 to.10. so its thickness varies and depends on the manufacturer. The metal layer is bonded with the help of adhesive, but many manufacturers use other types of bonding, such as some use vapor deposition and other use adhesives.

Rigid PCB vs. Flex PCB

The difference between flexible and rigid can be guessed from their names. Flexible pcb PCBs are flexible and can be bent and fixed into a system. Rigid PCBs, on the other hand, are inflexible and would not fit into a system.

The flexible circuits could flex thousands of times without any failure. At the same time, a rigid PCB could not bend into a course.

Flexible PCBs are considered costly because they provide customers with limited space, medical devices, and automotive applications. Rigid PCBs are not very expensive; that is why they are popular. They are used in many consumer electronic devices and have great space.

Although rigid PCBs are less expensive, flex PCBs target the siphon market due to their versatility and flexibility.

Types of Flex Circuits:

The Flexible pcb PCBs consist of many types. Here are some popular types of flexible PCBs.

1: Single-Sided Flex:

This is the most fundamental type of circuit. As the name suggests, single-sided flex consists of one layer of metal traces on the dielectric layer. The underside has a polymer or polyamide layer. The purpose of this extra layer is to prevent the circuit from becoming degraded or damaged. Also, it is suitable for insulation.

2: Flex with two sides:

Double-sided flex has two metal traces over the dielectric base layer. These two layers feature openings for establishing contact with one another.

3: Multi-Layer Flexibility:

In multi-layer flex, there are more than two layers over the dielectric layer. To build connections, these layers feature holes. The relationships in this layer are more complex, and the design could be more problematic.

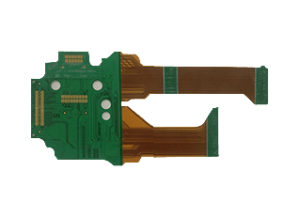

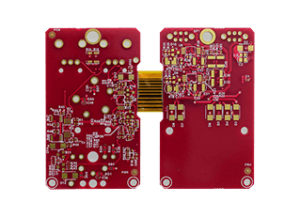

4. Rigid-Flex pcb:

Similar to a multi-layer flex, but with pre-preg film connecting the layers, a rigid-flex circuit is a flexible circuit board. There are no holes through the layers. This type of circuit has more density than other types of flex circuits. Most circuits available on the market are rigid-flex PCBs and flex circuits.

The Advantages of Flexible Printed Circuit Boards

Electronic devices are part of our lives in this advanced world of technology. The electronic devices that we use daily range from mobiles to servers. These electric devices are based on flexible circuits, regardless of size and use. As a result, today’s electronic devices range widely in form, factor, and purpose, yet they all share one thing in common: flex PCBs. Some benefits of pcb flex are as follows:

Advantages of Using Flex PCBs

- Flexibility is the most prominent benefit.

- The pcb flex is so flexible that they allow placements and can even fold.

- A 3-axis connection is necessary for the electric device that uses one of these flexible PCBs.

- It does not need any wiring, so there are low chances of connection failure. It enhances the reliability of electronic devices.

- Savings in Space and Weight

- Rigid PCBs are 60% higher in space and weight. Flex PCBs save space and weight.

- Bending Cycles

- The bending cycle of flexible PCB is as much as 200,000 without any failure. Because of this, 3D models often incorporate it.

- Anti-Vibration Benefits

- The flex PCBs are so light and flexible that they reduce or sometimes absorb the vibration. So it reduces the effect of vibration on the board and the associated joints.

- Use in a Harsh Environment

- The material used to build flexible circuits can even operate in harsh environments. The material is also shock-proof, moisture-proof, corrosion-resistant, and water-proof.

- Consistent with thin inner layers

- Heavy Copper Layers

- The use of thick copper layers is possible with the usage of thin copper layers. It provides high power output with flexibility.

The Top 5 Flexible Circuit Board Manufacturers

The top 5 flex pcb manufacturer are as follow:

Unimicron is a famous flex PCB manufacturer. They are also part of the world’s leading PCB company. They promise to supply only high-quality flex-PCBs.

RayMing PCB and Assemblage

This manufacturer is also a good choice for flex PCBs. They provide flexible PCBs and complete PCB services such as assembling, packing, and prototyping.

DSBJ

DSBJ is also a well-known flex PCB manufacturer. It is the most important reason to buy it because it is an essential feature.

Tripod Technology

The tripod technology used for manufacturing is also famous for flex PCBs. They specialize in assembling, prototyping, and designing.

China PCB manufacturer:

This manufacturer also has a unique and reputable name in flex PCBs. They promise to supply only high-quality flex-PCBs.

Conclusion

Flex PCB is a growing technology we use daily in things like laptops, cell phones, servers, and many other things. Flex PCB boards are in high demand due to their ability to incorporate lightweight and fewer space-consuming circuits. It can be attached to devices in different ways, making them more reliable and reducing the time it takes to put them together. With flex PCBs, the cost of putting things together goes down. Our flex PCBs have made our lives easier without our knowledge.