PCBs are an essential part of modern life and have made it possible to create more and more complex technology. One of the most interesting applications for printed circuit boards is in the medical field, even though printed circuit boards are found everywhere, from computers and cell phones to medical equipment. Medical PCBs are playing a vital role in the medical industry. They are used in various medical equipment such as surgical instruments, ECG machines, anesthesia machines, X-ray machines, and so on.

Medical equipment has become seriously reliant upon printed circuit boards to keep people alive and well. Printed circuit boards (PCBs) have become critically important in the medical field. As technology has evolved, more and more diagnostic, research, and treatment methods have become computerized, making PCBs for medical equipment a standard requirement.

So, let’s discuss what are Medical PCBs and why are they so important in the medical field?

What is Medical PCB?

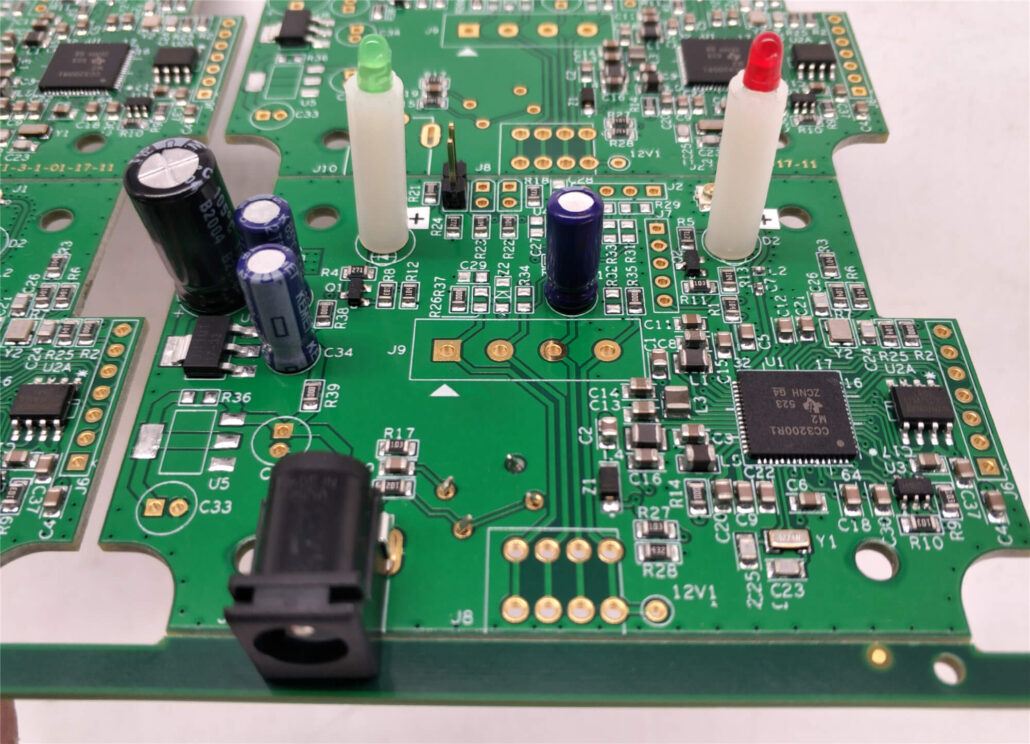

Medical PCB is a piece of electronic board required to operate different medical devices such as defibrillators, MRIs, medical imaging systems, CT scans, etc. Medical PCBs are essential because they allow medical devices to function properly. If you think of a computer as a specialized calculator, medical PCBs perform the same task for medical devices. They act as an interface between the major components of diagnostic, therapeutic, and monitoring devices.

Medical PCBs are the backbones of all medical equipment; they contain a lot of electronics. Different parts of equipment can then use these signals to perform different functions. Such as starting compressors, getting information about the patient, pumping contrast for CT scans, sending high voltage outputs for defibrillators, and so on.

Types of PCBs for Medical Industry

Depending on the application, several different medical PCB types are used within the medical industry. Each of these types comes with its specific characteristics and applications. The medical PCBs used in medical devices typically maintain a sanitary level of cleanliness to prevent harmful contaminants from entering the human body. At the same time, they also need to withstand high temperature and humidity levels to avoid damage.

Two of the most common types of medical PCB

Medical electronic products are extremely complex, and all the circuits in the product must be working perfectly for the device to function properly. The circuit boards inside these devices cannot afford to have even one miss-soldered wire or broken trace on them, as that could lead to serious personal injury or even death. That is why many types of Printed Circuit boards can be used in medical electronic products. For example, single-sided, double-sided, and multi-layer PCBs are often used in a wide variety of medical electronic products. They’re designed to be flexible or rigid depending on the product’s intended usage.

Widely used medical PCBs

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat.

Medical PCB Assembly

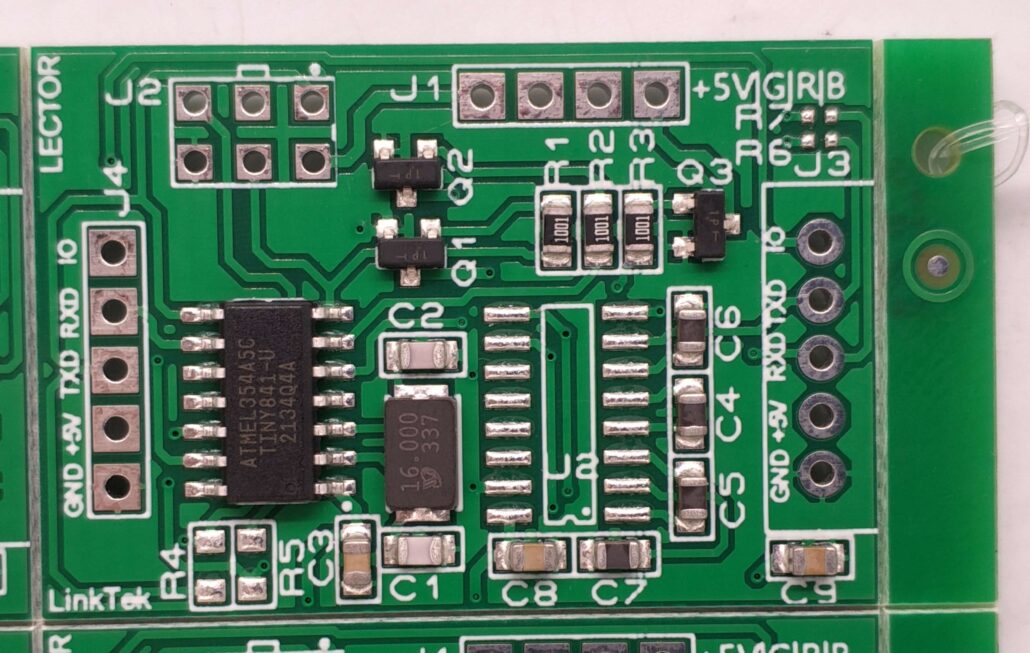

High-Density Interconnect (HDI) PCBs

High-Density Interconnect PCB or HDI PCB is one of the most common types of PCBs used in Medical Devices nowadays. The HDI PCB meaning medical circuits ensure high-speed data transmission, and that is why it is the most preferred boards in most medical devices.

Although they are a little expensive, they are essential for important medical devices where device response times can mean life or death.

High-Density Interconnect PCBs does use in most medical devices as these are immune to noise and electromagnetic interference. The high-density interconnection of HDI PCBs enables speed communication and true floating-point input that can be used in most medical devices like multi-modal physiological monitors and ECG monitors.

Medical PCB Assembly

Flex PCBs

Flex PCBs are highly demanded in medical devices as they are more flexible than other PCBs and offer more flexibility in design. Medical Flex PCB is a patterned arrangement of printed circuitry components that utilize flexible-based material (FPC) with or without flexible covertly.

Flex PCBs designs are becoming more and more important in the medical device industry. Many devices that can utilize to prolong life or cure illnesses need durable boards that give them high-quality performance without any interruption.

They design to withstand temperature fluctuations and are waterproof, sterilized, and rebuilt repeatedly.

Medical PCB Assembly

Rigid PCBs

Rigid PCBs are solid, inflexible Printed Circuit Boards that have numerous applications in the medical industry. Some primary examples include x-ray machines, incubator and defibrillator monitors, ECG machines, chemotherapy pumps, and more.

Medical devices are some of the most critical products used in a hospital. Due to the risk to human life, they should be error-free. Because of this, most medical device companies use rigid PCBs rather than other PCBs. because these medical PCBs are solid and can withstand liquids and temperatures.

There are several different types of rigid boards like aluminum core PCBs, glass epoxy PCBs, etc. However, many medical devices opt for multi-layer rigid PCBs due to their versatility and various features they provide.

Application of PCBs for Medical Industry

Medical PCBs uses in various fields: they can implement in aerospace, agriculture, and even meteorology. However, Medical PCBs are one of the most important areas of usage. They do use medical equipment such as X-ray machines and MRI scanners. Medical PCBs are critical for the healthcare industry because they help provide high-quality treatment results in the quickest time possible.

The medical PCB industry is growing day by day, and with the advancement of medical science and technology, various electronic devices do use in different medical applications. Modern-day hospitals, research laboratories, and drug manufacturing companies use the latest technological developments to offer quality services to patients.

The growth of the medical electronics industry has boosted the use of PCBs in it. Medical PCBs can use widely in different medical applications within the industry, including electrocardiography devices, ventilators, radiology, other imaging devices, glucose monitoring systems, and thermometers.

Different types of PCBs can use widely in the following medical applications.

Medical Monitoring Devices

Medical Monitoring Devices does use in an extensive range of diagnostic and treatment procedures, from simple pulse rate measurement to highly skilled surgery. To ensure that these procedures are carried out successfully and with the greatest safety, an array of sophisticated medical devices is increasingly being used.

So, Medical PCBs use widely in different Medical Monitoring Devices such as:

- Body Temperature Monitors

- Blood Glucose Monitors

- Blood Pressure Monitors

- Heart Monitors

- Heart Pacemakers

- Nerve Stimulator Unit

- Infusion Fluid Controls

- EMG Activity Systems

- X-ray Computed Tomography

- Peristaltic Infusion Technology

- Flow Rate and Dispensing Systems

- Electrical Muscle Stimulation Equipment

Implantable Medical Devices

Medical PCBs does present in Implantable Medical Devices, providing a wide range of functions throughout the body.

An implantable medical device does use to replace any defective organ in the body. It does implant directly into a patient’s body and works as a substitute. The most common devices are heart pacemakers, artificial kidneys, and cochlear implants.

Medical PCBs does more commonly use in these devices, and they have become an integral part of these devices. The locations and functionality of Medical PCBs vary from device to device and the specific tasks they process. For example, in coronary stents located inside the arteries of cardiac patients, the PCB monitors heart rates and transmits data back to physicians’ offices.

Medical Diagnostic Devices

Medical devices do use for detecting, acquiring, and displaying medical images as well as other vital information concerning the human body. PCBs uses in different medical diagnostic devices such as:

MRIs (Magnetic Resonance Imaging):

MRI unit uses a powerful magnetic field to form high-resolution images of various body parts. The image is made by spinning the patient inside the magnetic field producing MRI (Magnetic Resonance Imaging) pictures that help doctors detect and diagnose diseases faster than current clinical procedures.

CT (Computerized Axial Tomography) Scans:

A CT scanner uses computer algorithms, special lenses, and x-rays to create sharp images of a patient’s internal body parts. This helps determine if there are any health concerns such as cancer, heart disease, or brain injury that is not visible to the naked eye.

Ultrasound Equipment:

Ultrasound equipment produces high-frequency sound waves that bounce off the patient’s body. The ultrasound machine then creates a picture of the structure and translates it into an image on a screen in real-time.

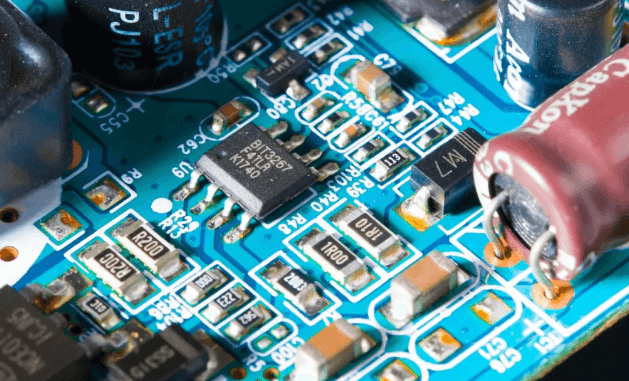

Medical Device Industry Printed Circuit Boards

Require medical equipment to save and improve patients’ lives. Recent years have seen a lot of technological advancements, causing today’s medical devices to be superior to those used several decades ago.

The medical device industry is always coming up with innovations, whether it be some sort of medical device or technology that helps to make these devices safer and more efficient. Medical grade PCBs are an undoubtedly valuable part of the medical device industry.

Printed circuit boards for medical devices provide a stable and cost-effective solution for designing, manufacturing, and testing electronic medical products. A printed circuit board increases productivity and efficiency in medical devices.

Medical Industry Rigid-Flex PCBs

Medical PCBs are a combination of one rigid and one flexible circuit board sandwiched together with other components in between. These medical PCBs can also call hybrid-flex circuit boards. Rigid-flex PCBs done to use for many different applications in the medical pcb industry for decades. They do use primarily because of their low cost, high flexibility, and ability to integrate with a wide range of components.

Why are Rigid-Flex PCBs Being Used in Medical Equipment?

Medical PCB medical is the sturdiest and most durable as compared to other boards such as the base flex and rigid PCB. The rigidity of a rigid-flex PCB makes it very durable; this is because the board doesn’t undergo any deformation when stress is applied to it. That is why Rigid-flex PCBs uses widely in medical equipment.

Rigid-Flex PCB meaning medical does use in many different applications today, mainly in the medical field. They allow for more connectivity options since there is no need for cables and connectors. Medical PCBs can particularly suit medical devices as they provide excellent environmental protection and allow for more portability.

Importance of PCBs in Medical Equipment

The application of pcb meaning medical is in such high demand in the medical pcb field that they consider the only real alternative to the more traditional methods of creating a circuit board. Medical equipment is generally meant to last for several years and may require replacement periodically due to obsolescence or general wear and tear. The demand for new equipment has led to a dependency on more recent technologies, including rigid-flex printed circuit boards.

In the medical pcb field, rigorous sterilization and clean procedures need to be considered. It is essential to use components with exactly the same high durability as that of medical devices. Rigid-flex PCBs are known for their high dimensional stability, robustness, and purity levels. Their resistance to chemicals, solvents, and gas makes them a valuable asset for the medical field.

Final Words

Medical pcb uses widely in medical devices such as diagnostic instruments and equipment, Laboratory equipment, and Bio-analysis instrumentation. So medical PCBs are playing a vital role in the medical industry. Medical equipment such as anesthesia machines, ECG monitors, surgical instruments, and X-ray machines use PCBs to function. These electrical components present on such devices refer to as Medical Printed Circuit Boards. These medical PCBs are specially designed to work in a variety of temperatures ranging from -40 to 140 degrees Celsius.