Introduction

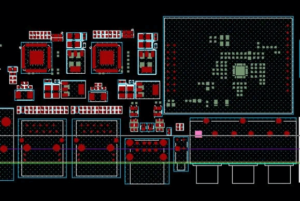

Constructing a PCB may entail many processes. You must assign person-hours to design your boards, ensure manufacturability, and check for design issues. On top of that, you also have to ensure that your PCB design house can handle all the requirements of your finalized board.

Faithfully following the processes above can help you avoid loss of profit, wasted project time, and management concerns. Additionally, it would be best to minimize mistakes during design/prototyping and manufacturing. With this, design respins can be prevented. Incidentally, choosing the proper PCB manufacturer can avoid headaches during manufacturing. Here are some things to consider:

1. Can they Handle your Board Design Requirements?

As a board gets complicated, so do the requirements for choosing a PCB manufacturing house. Usually, circuit speed issues, unique component handling, and finer line space width ratios become factors. Knowing if your PCB manufacturer can handle these requirements is essential. You can check your manufacturer’s website for their design capabilities. They usually list it in a table. Contact your manufacturer if you need help finding your detailed requirements.

2. Can your Manufacturer’s Lead Time Meet the Timeline of your Project?

Lead time is the time your PCB manufacturer needs to deliver your boards to you. Usually, because of advanced manufacturing, the lead times have become shorter and shorter. However, remember that lead times have nothing to do with your board’s overall quality and correctness. There may even be times when you have particular design requirements that need time and attention. With this, discussing accurate lead times with your manufacturer is essential.

Another thing to consider is the time needed to transport your boards to you. Many overseas PCB manufacturers deliver your goods by sea or air. Choosing a suitable freight carrier can have an impact on your lead time. You may have a shorter delivery time if you choose a local PCB manufacturer.

3. Do they have Industry Certifications?

Different industry certifications ensure the quality and safety of your manufactured boards. They come from various regions and organizations. Listed below are some of them:

-

ISO9001

ISO9001 is one of the most famous and accepted certifications globally. This certification focuses on Quality Management Systems (QMS). Through this, establishments continually improve the quality and reliability of their products and services. Incidentally, companies and organizations can have an external audit regarding their compliance with ISO9001. This approach enhances the organization’s compliance with this standard.

-

UL

Short for Under Writer’s Laboratory, UL is a product safety certification from the United States. They perform product safety tests that ensure the safety of consumers in using their tested products. You may have seen the UL safety mark imprinted on several PCBs, indicating it has passed this standard.

-

IPC Standards

IPC stands for Institute for Printed Circuits. It’s a body that produces standards relating to the design and manufacturing of PCBs. IPC encompasses all the stages of PCB development, including design, material selection, qualification, and manufacturing, among others. Note that IPC standards break down into several sub-categories, such as (IPC-A-600) Acceptability of Printed Boards, (IPC-A-610) Acceptability of Electronic Assemblies, (IPC-2221) Generic Standard on Printed Board Design, (IPC-6012) Qualification and Performance Specification for Rigid Printed Boards, and several others.

4. Does your Manufacturer have enough Experience and Expertise?

Different PCB fabrication and assembly houses started from different beginnings. Some started as electronics goods retail providers. Some were initially electronics design/prototype houses. Others ventured into circuit board production immediately. Their background says a lot about their experience and capabilities.

It’s also important to check your company’s background and history. Companies that merge with other companies would have a larger scope of capabilities. For example, a PCB fabrication house that merged with or bought a logistics company would likely excel in areas requiring logistics. Another company with a cloud data center should have a centralized database with global real-time inventory capabilities.

A company’s years of experience should say a lot about them. You should see companies with 15, 30, 50, or more years of experience. They indicate a company’s willingness to stay on track and keep their goals.

5. What is their Volume of Production?

You must note that different PCB manufacturers may have other targets for volume production. There may be houses that are fitted for prototypes and small batches only. Usually, these companies target electronics hobbyists and small design houses. Their maximum volume production can range between 300 to less than 1000 pieces.

On the other hand, some companies can handle large-scale volume production. Large companies may accept orders between 1,000 and 100,000 units, depending on their capabilities.

The best approach is to research beforehand before delving into quoting your boards.

6. What is their Cost of Manufacturing?

Cost is one crucial parameter in PCB production. These days, every single cent counts. Volume production can scale up the cost of any PCB design project. With this, it’s essential to check your PCB manufacturer’s cost beforehand.

Many overseas PCB manufacturers in China offer cheap manufacturing due to cheaper labor, a larger global inventory of components, and a scaled-up PCB assembly process. However, since they may be far from you, ensure adequate research and establish proper communication with them to ensure the quality and reliability of your boards.

7. Where is your PCB Manufacturer Located?

The internet has made doing business in different locations seamless. However, this does not mean you have to forego different areas of geographical concern. One such area is the language barrier that can arise when doing business. Ensure that you and your PCB manufacturer understand each other well. Do they speak or write clear English enough to do high-value transactions?

Another area to look at is the lead times and possible issues during transport. The distance between your manufacturers impacts your lead time because your manufacturer transports your goods with an approximate arrival date. There can be unforeseen issues during this timeframe. Depending on the transportation cost, volume, and delivery time, you may have to decide if you’ll ship them through sea or air. You also have to handle customs declarations and fees appropriately. Having a freight forwarder can help in this area.

8. What are your Manufacturer’s Testing Capabilities?

A good product coming from manufacturing should have gone through rigorous testing. This process ensures that your PCB or assembled boards are free from defects or errors. Most PCB manufacturers employ different kinds of testing methodologies. Note that these methods catch different types of faults and have varying levels of success in seeing them. Below are some examples of PCB and assembly testing:

-

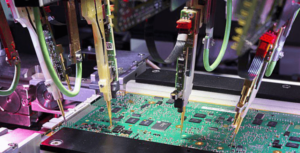

Flying Probe Test

A flying probe test is a computerized form of testing that uses electrical probes to catch shorts or open circuits on your board and other electrical parameters. A set of test points on your PCB will help the flying probe test. Note that flying probes do not require custom fixtures that may add additional cost to the customer.

-

In-Circuit Test

This test uses both custom fixtures and probes to test your boards. Your manufacturer can do ICT after populating your boards with components. It should test component values, orientation, circuit continuity, and other electrical parameters. An ICT test is generally faster than a flying probe test as it can test several test points at the same time. The test is suitable for high-volume production, justifying the cost of building a custom test fixture.

-

Manual Visual Inspection

It makes sense for an individual to inspect your boards manually. You’ll never know if a machine failed to catch a defect on your board. Note that the person should be well-trained by the company in seeing different board issues.

-

Environmental Testing

Environment testing is well-suited for a commercial product as this will test your boards with various temperatures and environments. Environment testing ensures that the consumers of your product can use it in your preferred region and climate.

-

Vibration and Shock Testing

Vibration and shock testing is a rigorous test process that will ensure the durability and ruggedness of your boards. It’s common to see these kinds of tests performed on boards for military and aerospace applications.

9. Customer Support and Communication

A company with good customer support can get repeat orders from the same customer. This process shows how they care enough about their customers. Note that during the manufacturing and testing process, it’s vital for the company to maintain constant communication with its clients. What if your manufacturer finds a DFM or a materials issue during the design acceptance process? Only through customer communication can these issues be solved. They can continue communicating with you until the boards are safely delivered.

10. Personally Visit your PCB Manufacturer

Inspecting a PCB manufacturer’s company and facilities ensures that all their capability and quality claims are valid. A personal meeting with the managers or bosses provides a healthy business relationship. You could also inspect if they faithfully follow their chosen industry specifications. During this time, you can discuss the preliminary requirements for your product. You may also visit other PCB manufacturers to make better choices.