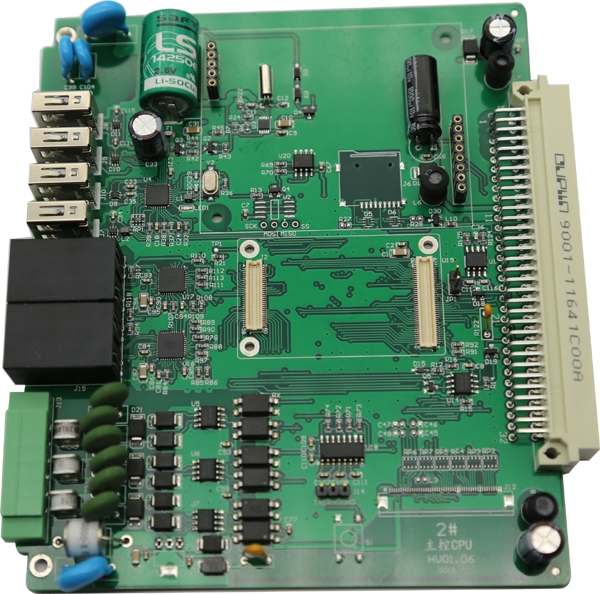

3D Printed Circuit Board Assembly

Printed Circuit Board Assembly is a complex process involving many different phases. And it is also the key process for realizing the functions of the final product. The in-house PCB assembly services provided by uetpcbmake ordering your turnkey PCB manufacturing and assembly a hassle-free experience. Because you can rely on the professional support team and 8 state-of-art assembly lines to help you navigate every step of the process. In this post, we define some of the basic knowledge of the Printed Circuit Board Assembly process, involving solder paste printing, SPI, Pick-and-Place, AOI, Reflow Soldering, PTH Assembly and X-ray. For detailed information, you can visit its specific page. As a PCB fabrication and assembly manufacturer, it’s necessary to let you know what our PCB assembly services are.

PCB Assembly Process:

Solder Paste Printing

Solder paste is a grey combination material used in the fabrication of printed circuit board assembly to connect surface mount components to pads on the PCB. It is also possible to solder thru-hole pin in paste components by printing solder paste in or over the holes. The solder paste printing stage of the PCB assembly process is vitally important. Through the windows of the SMT stencil, the solder paste will be printed onto the pads of bare PCB with our Automated Solder Paste Printer from the USA.

SPI

It is the next step of the PCB assembly process that is the abbreviation of Solder Paste Inspection. Which is to check the solder paste deposits quality on the pads. SPI process makes our PCB assembly services apart from those PCB manufacturing and assembly suppliers who haven’t such machines. We can 100% conduct this inspection with our KY-8030-2 made by KOH YOUNG from South Korea. SPI can improve PCB assembly quality, production yield, and the performance of the PCBA in the finished product. By making your Printed Circuit Board Assembly projects under our manufacturing roof, you will be more confident in launching your products to the market.

Pick-and-Place

SMT component placement systems, commonly called pick-and-place machines. When the bare PCB, covered good quality solder paste, comes to SMDs pick-and-place process, our advanced robotic machines Fuji NXT-II /NXT-III /XPF-L, and Panasonic NPM-D3 /NPM-TT2 machines will play the key role in the Printed Circuit Board Assembly to place SMDs onto a printed circuit board. Good robotic machines will lead to high placement precision and make us apart from other PCB manufacturing and assembly providers once again.

AOI

Automated Optical Inspection is a visual inspection of printed circuit board assembly with uncovered metal shields before reflow soldering or those PCB assemblies without metal shields after reflow soldering. The CCD camera of our OMRON VT-RNS from Japan autonomously scans the device under the test for both catastrophic failure and quality defects. It does commonly use in the PCB manufacturing process because it is a non-contact test method. AOI can implement at many stages through the manufacturing process. If the PCB assembly services are from your supplier are without AOI, how can they be trusted and reliable in production yield?

Reflow Soldering

Without the precise placement by AOI, there are no defects. Pcb has the component bonded printed circuit board assembly will transport to the reflow oven. This melts and cools the solder paste between the component and the pcb, enabling the actual component to be soldered. Our Heller 1913 MK3 and 1936 MK5 reflow ovens from the USA consist of a number of heaters. Its main function is to heat the board to a precise temperature. And it also controls the degree of cooling as the solder hardens. This process is crucial to the creation of properly functioning electronics.

PTH Assembly

PTH Assembly is a method of soldering electronic components in place by hand using drilled holes in the printed circuit board assembly and connecting pads. This technique creates a stronger physical bond of the component to the PCB board. But it is much more time consuming. And the cost of the PCB can increase due to the higher volume of drilled holes.

X-ray

When the finished PCB assembly passed the reflow oven, and /or AOI, it will pass our x|aminer (Phoenix) X-ray inspection. With the application of high-density packaging technology, the PCB assembly services provided have also brought new challenges to non-destructive technology. In the PCBA industry, the assembly quality of components is getting more and more attention from PCB fab and assembly providers, like uetpcb. Components are soldered on the PCBA board, the soldering of the components cannot be seen from the appearance. Therefore, the X-RAY equipment is used to test the soldering, and the soldering bubbles are observed.

Except for this basic knowledge of Printed Circuit Board Assembly. You can check to know more about our PCB assembly services on the related pages, Visual Inspection, First Article Inspection, In-circuit Testing, and Functional Testing.