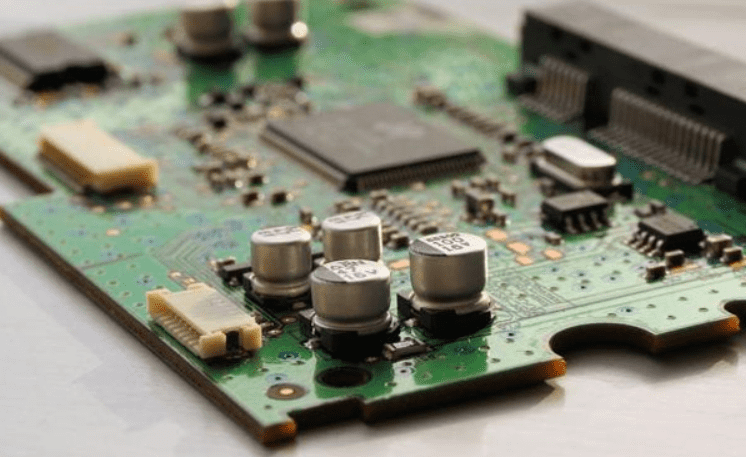

The PCBA processing process involves PCB manufacturing, components sourcing and checking, SMD assembly, DIP process, programming, testing, aging and a series of the process, If the supply chain and manufacturing chain too long. it will cause many PCBA boards happen failures. But the quality control of PCBA process will avoid the most of failure of PCBA board. Therefore, most professional PCB assembly manufacturers have the quality control of PCBA process to ensure the quality of PCB assembly service they have. It is important for PCB assembly to create the quality control of PCBA process, and this article will provide what are some of the ways to quality control PCBA process.

- PCBA manufacturing

It is especially important to hold a pre-production meeting after receiving a PCBA order. Mainly for technique analysis of PCB Gerber files and submit design for manufacturability report (DFM) according to different customer needs. Many small manufacturers do not take this seriously, but tend to prefer it. Other important work for PCBA manufacturing is the inspection of PCB design. As the basic of PCB assembly, the PCB design decides the quality of PCBA manufacturing. It is not only easy to produce poor quality problems caused by poor PCB design, but also a lot of rework and repair work.

- PCBA components sourcing and checking

Components sourcing is also an important part of the quality control of PCBA process. Procurement channels for components need to be strictly controlled and must be obtained from large traders and original manufacturers to avoid the use of second-hand materials and counterfeit materials. In addition, a special PCBA inspection post should be set up to strictly inspect the following items to ensure that the parts are trouble-free.

PCB: Check reflow oven temperature test, whether the hole without flying line through is blocked or ink leakage, whether the PCB board surface is bent, etc.

IC: Check whether the screen printing and BOM are identical, and carry out constant temperature and humidity preservation.

Other common methods: Check screen printing, appearance, electrical measurement, etc.

- SMT assembly

Solder paste printing and reflow furnace temperature control system are the key points of PCB assembly, which need to use the laser steel stencil which has higher quality requirements and can better meet the processing requirements. According to PCB requirements, part of the need to increase or reduce the stencil’s hole, or U-shaped hole, just according to the process requirements to make the stencil. The temperature control of the reflow oven is very important to the wetting of the solder paste and the solderability of the steel stencil, which can be adjusted according to the normal SOP operating guidelines.

In addition, strict implementation of AOI testing can greatly reduce the adverse effects caused by human factors.

- DIP process

In the DIP process, the die design for wave soldering is the key. How to use the mold to greatly improve the yield, this is PE engineers must continue to practice and summarize the process.

5.PCBA board testing

For orders with PCBA testing requirements, the main test contents include ICT (In-Circuit Test), FCT (functional test), Life Cycle Testing(aging test), temperature and humidity test, drop test, etc.