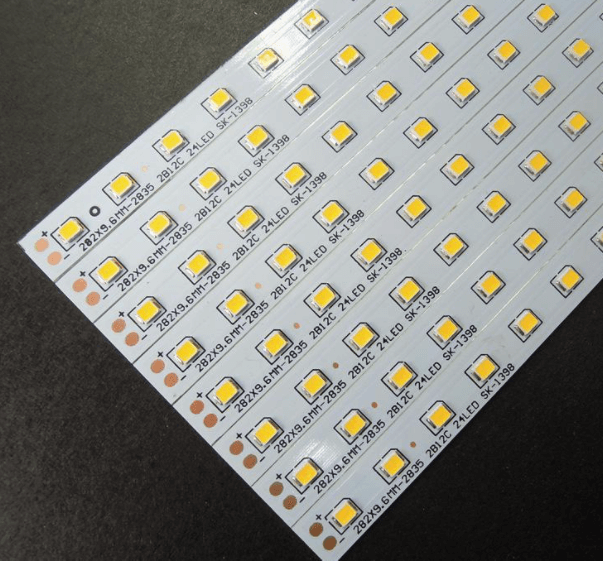

A printed circuit board (PCB) is composed of several layers of insulating material and copper. It forms an electrical pathway between electronic components such as semiconductor chips, resistors, capacitors, etc. The term printed denotes fabricating the circuit; it is unrelated to the text displayed on a user interface or printed on paper.

Top Characteristics Which You Need To Consider While Choosing A PCB:

1) Material:

This is the most important factor to consider when you are choosing a PCB. The material of PCB is based on the application, which determines properties like thermal conductivity, tolerance to temperature, expansion, etc. In addition, RoHS compliant boards meet the European directive, which restricts 6 hazardous materials found in electronic components.

2) Design Rules:

Design rules define how difficult it is to manufacture certain features on a given board design. Therefore, there is an increased possibility that manufacturing defects may be introduced in the board design with higher design rules. On the other hand, lower design rules can be more prone to such defects.

3) Thickness:

These days PCBs have 0.8mm thickness as default but will depend upon your requirement and choice of material as well as PCB design software. In addition, many PCB fabrication companies have the option to do multi-layer, double side, and HDI boards.

4) Copper Thickness:

The copper thickness is an important factor determining the current carrying capacity, signal strength, and distribution of heat produced by electrical components on the board. The common specifications are 1oz (31.5mil), 1/2oz (63mil), and 3/4oz (85mil).

5) Layer Count:

Layer count is the number of copper layers in a PCB. It varies from 1 to as high as 20 or more. The more layer count, the higher cost and time associated with manufacturing it. Usually, 4 layer boards are sufficient for most applications and provide good value addition and ease of assembly and soldering function.

6) Board Size:

Board sizes range from a few millimeters to hundreds of kilometers, depending on the requirement of your project. It is important to carefully consider the size of a board as it affects its cost, ease of assembly, and geometry compatibility with other components.

7) Cost:

This factor depends on the size of the project or volume requirement of your order and many more factors like manufacturer’s location, the technology used (complex PCB design), board thickness, layer count, number of colors required, surface finish, etc. Of course, there are budget suppliers where price plays a major factor, especially when you don’t want to invest in expensive equipment, but for someone who’s starting up, it’s better to go with more reliable suppliers with better quality and warranty.

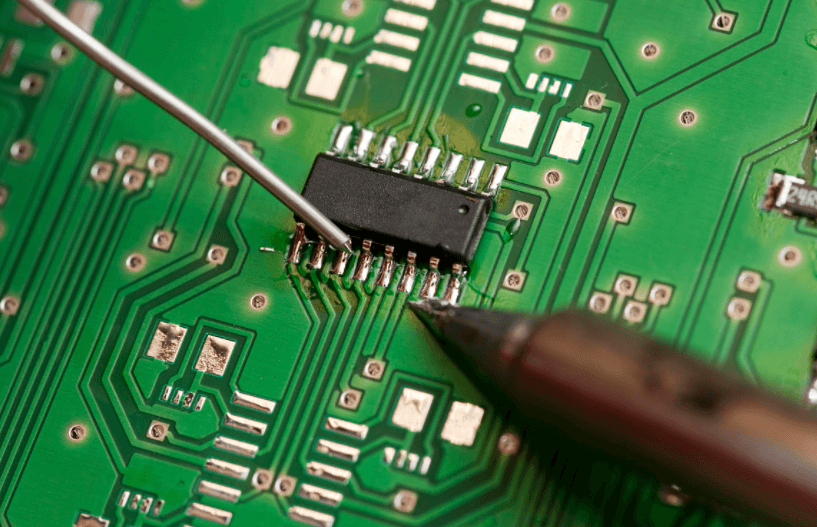

8) E-Test:

This is a new emerging standard that needs to be considered by all the buyers of PCBs while ordering. After fabrication, companies test the boards for electrical continuity and any defects in design or manufacturing before they ship them out. This ensures zero defective boards reach the assembly line and cuts down on rework costs.

9) Quality Testing:

Consistent quality testing of printed circuit boards ensures that all products are manufactured to the highest standards. Choose a supplier who provides you with online access to your order history and test results. This information is crucial for identifying defective products, process problems, or design issues during production.

10) PCB Manufacturing Speed:

Manufacturing speed depends on various factors like layer number, board thickness, the material used for fabrication, design complexity (more the layers higher is the manufacturing time), etc. For example, PCBs with 4 to 5 layers take one to two days, while those with 6 to 9 layers may require three to five days. Boards with 10 or more layers can take anywhere between five and ten days.

11) MOQ (Minimum Order Quantity):

This depends on a variety of factors like technology, size, thickness, etc. You will have to contact the PCB firm directly to check what’s their MOQ requirement.

12) Customization Options:

It’s important to check the customization options provided by a PCB supplier. For example, ask about part orientation, solder mask color (if any), silkscreen options (various colors and thicknesses are available), component layout guides, etc.

13) Surface Finish:

This depends on the requirement of your application, and it involves processes like HASL, HAL, Gold/Tin plating and ENIG, etc. For example, HASL means hot air solder leveling, which is a no-clean process. In contrast, others involve cleaning or stripping processes before they are shipped out to avoid any oxidation issues during assembly line production, so these methods mean higher costs and more time consumed.

14) Signal & Power Integrity:

Signals have to be routed carefully, considering impedance, signal integrity, and EMI interference which may affect the overall working of your design. Other factors that can interfere include thermal effects from nearby components or solder joints with high temperatures during soldering processes.

15) Via Types:

These are important to consider while designing a PCB where 1) through hole vias provide large area connection between 2 layers 2) micro via provides high density, which is vital in PCBs with more than 16 layers.

16) Working Temperature:

This depends on the type of components you’re using for your project. Your choice also depends on many other parameters like power dissipation, thermal resistance, thermal expansion rate, etc., so it’s crucial to select the right temperature range by calculating the number of heat cycles experienced during your product’s production and life cycle.

17) Types of Boards:

There are different types of PCBs available, so you will have to choose based on your application requirement. However, single-sided (SS), double-sided (DS), multi-layer, rigid-flex boards are the common types of printed circuit boards.

Conclusion

It’s great to know more about the manufacturing process before you invest in a PCB prototype. I hope this article has given you some insight into the importance of selecting a PCB for your next project. It is important to know what features are most important and how they affect design time or cost. If you would like more help choosing a printed circuit board that meets all of these criteria, just click here! We’ll be happy to offer assistance in finding the right PCB for your product development process.