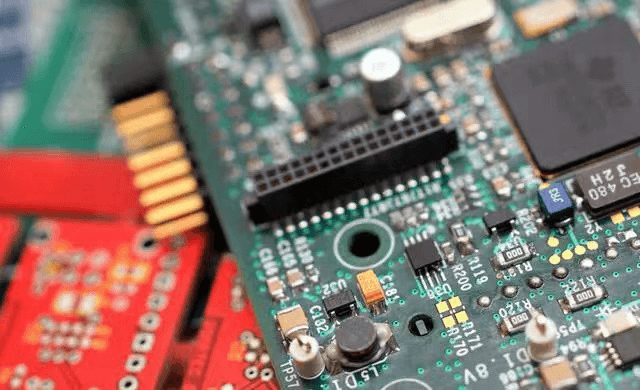

Manufacturing circuit boards is a procedure which takes time and isn’t thought to be a “simple thing” to do. Although, there are enthusiasts that can make their own boards at home with the proper stuff, but they usually have a tendency to be less complex as machine made ones. Also, it would be quite time consuming to hand make 20,000 PCBs. Below will briefly walk you through the PCB assembly service procedure and what’s involved at every stage.

PCB assembly service is also called Printed Circuit Board Assembly, that is solder the electronic components to a printed circuit board, they are technically referred to as Printed Circuit Assembly or Printed Circuit Board Assembly.

Keep in mind that circuit board assembly isn’t necessarily the same as circuit board manufacturing. When you produce PCBs, it entails several procedures which include PCB Design and really producing the PCB prototype. Before the board may be ready to use in electronics or gadgets, then the appropriate components need to be inserted by soldering them. The kind of components and the process of the meeting depend on the type of circuit board it is, type of digital components that need to be connected, and what digital device the board is going to be added to.

Thus, following the PCB is completed being made, it is time for the various electronic components to be attached to it in order for it to really be functional. There are two types of construction methods utilized for the meeting.

1) Through-Hole construction:

Part leads are inserted into the holes

2) The surface-mount construction:

Components have been set on lands or pads onto the outer surfaces of the PCB.

But in the two construction kinds, the component leads remain electrically and mechanically fixed to the PCB with molten metal solder.

Based on the quantity of boards that need to be assembled will determine the way the components are going to be soldered. If it is for a high production quantity, then soldering elements to the Printed Circuit Board is done by machine positioning. Machine placement is done with majority wave soldering or reflow ovens. Otherwise, when the production quantity is for little volume prototypes, soldering by hand works just fine in many cases (Ball Grid Arrays are actually impossible to solder by hand).

Frequently, through-hole and surface-mount structure needs to be performed at 1 PCB meeting because some needed electronic components only available in through-hole packages, while some can only be gotten in surface-mount packages. Also, it’s a good reason to utilize both of those methods during precisely the same meeting because through-hole mounting can actually provide additional strength for the digital components that are likely to experience some physical stress. If you are aware that your PCB isn’t going to experience any bodily strain, then it can be advisable to use surface-mount techniques in order to occupy less space on your board.

Following the parts are fully assembled on the PCB, it’s almost always best to test to ensure that the board works correctly and into the functionality required. Here are a few of the ways that they are analyzed as soon as they have been assembled.

1) An easy visual inspection:

to ensure there are no electrical components out of place on the circuit board. It’s also a good time to double check all the soldering. (Electricity is off)

2) Analog Signature Analysis:

when you applied a current-limited AC sine wave across two factors of the electric circuit and components. (Electricity is off)

3) Performing an In-Circuit Evaluation:

checking various physical dimensions with the board such as voltage, frequency, etc. (power is on)

4) Performing a Functional Evaluation:

verifying the circuit board actually does what it’s intended for. (Power is on)

If a few of those printed circuit boards neglect any of the aforementioned evaluations, not all is lost. You are able to learn where the issue is occurring and replace the failing board or components to allow for it to pass. This may be referred to as reworking.

Circuit boards and also the manufacturing process for them is not just complicated, but a vital part for many businesses across the world. With improvements in technology and capabilities of outsourcing, US industry leading printed circuit board generates have needed to go over and beyond to remain in business and provide service that is unparalleled to local and international competitors.

Circuit boards are one of the leaders and we welcome you to visit our website in order to receive even more info about PCB Design and the procedure involved.