Features of high frequency circuit board

-

High efficiency

High frequency pcb dielectric constant value is very small. The dielectric constant value will lead to delayed signal transmission. High frequency pcb with small dielectric constant, the loss will also be small. So China high frequency pcb energy consumption is small, high efficiency. And advanced induction heating technology can achieve the target heating needs. Of course, the focus on efficiency and the characteristics of environmental protection are very suitable for the development of today’s society.

-

Fast speed

The value of high frequency pcb design loss factor is much smaller. Scientific research shows that the transmission speed is inversely proportional to the square root of the dielectric constant. That is, the lower the dielectric constant, the faster the transmission speed. This is the advantage of high frequency pcb. It uses special materials not only to ensure the characteristics of the small dielectric constant but also to maintain the stability of operation, which is very important for signal transmission.

And high frequency pcb design is the full range of signal performance. As the frequency of the transmission line increases, signal loss becomes more and more severe. But High frequency pcb reinforced epoxy or PTFE materials can provide a much lower loss factor, thus helping to reduce signal loss -

The adjustable degree is large

High frequency printed circuit board use widely in various industries. The high frequency pcb of precision metal material heating treatment needs, in its field of process, not only can realize the heating of different depth parts but also for the local characteristics of the key heating. High frequency printed circuit board whether surface or deep, centralized or decentralized heating method, can be easily completed.

-

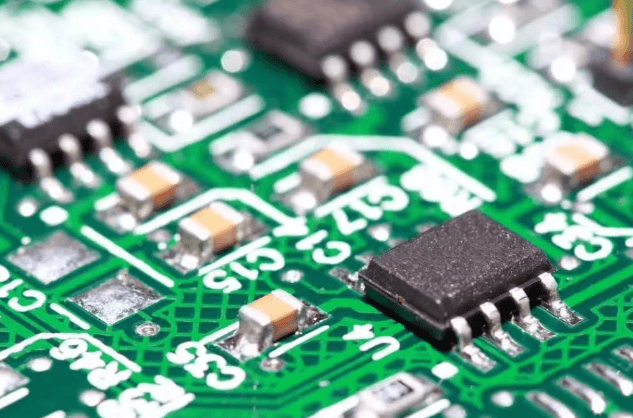

Strong resistance

Dielectric constant and dielectric, the environment will have specific requirements, especially in the south, humid weather will seriously affect the use of circuit boards. High frequency circuit boards made of materials with very low water absorption can challenge such an environment, but also has the advantage of resistance to chemical corrosion, moisture resistance, and high temperature as well as great peeling strength, so that high frequency circuit boards play a strong performance.

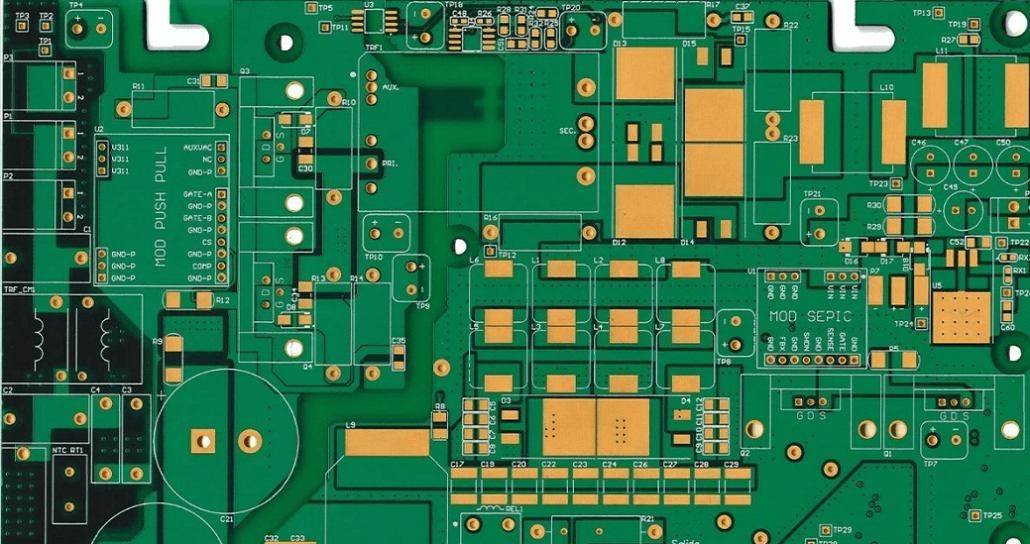

High frequency pcb materials

-

FR-4

When selecting a PCB substrate for high frequency circuits, pay special attention to the materials used. For many years, the standard circuit board material currently used in the market has been FR-4, a flame-retardant type 4 woven glass-reinforced epoxy laminate. This high frequency pcb materials are very cost effective and easy to use, making it ideal for high frequency pcb manufacturers as FR-4 material. It is also a perfect electrical insulator and a robust material for printed circuit boards.

-

Rogers, Isola, Taconic, Dupont, and Megatron

If there are a requirement for high frequency pcb in terms of signal transmission at high speed or characteristic impedance control requirements. In this case, the focus is on the DF and its performance under frequency, temperature, and humidity conditions. The choice of PCB board must be to meet the design requirements, mass production, cost in the middle to strike a balance.

In simple terms, the design requirements include the electrical and structural reliability of the two parts. Usually, in designing a very high-speed PCB board (greater than GHz frequency), the board issue will be more important. For example, now commonly used FR-4 material, in several GHz frequency dielectric loss Df (Dielectricloss) will be very large, may not be suitable.The most common high frequency pcb are Rogers, Isola, Taconic, Dupont, and Megatron materials. All of these materials typically have low Dk and low loss. -

Teflon and flexible substrates

In terms of price, FR4 is the cheapest compared to dedicated high-speed materials and Teflon, with Teflon being the most expensive. However, the performance of FR-4 starts to degrade when the signal speed exceeds 1.6 GHz. Therefore, DK, Df, water absorption, environmental survivability, next-generation substrates, Teflon, and flexible circuits are the best choices.

If a printed circuit board requires frequencies above 10 GHz, next-generation substrates, Teflon, and Flex substrates are your best choices because they are far superior to traditional FR-4 materials. Another consideration for making high frequency pcb is the moisture absorption rate of the material used in the board.

Even a tiny amount of moisture can change the electrical properties of a high frequency circuit. Traditional FR-4 can absorb up to 50% moisture, while high frequency pcb materials such as PTFE can absorb as little as 2%. That’s why high frequency pcb manufacturers generally choose FR-4 materials first.

Application of high frequency circuit board

If a printed circuit board requires frequencies above 10 GHz, next-generation substrates, Teflon, and Flex substrates are your best choices because they are far superior to traditional FR-4 materials.

Another consideration for making high frequency pcb is the moisture absorption rate of the material used in the board. Even a tiny amount of moisture can change the electrical properties of a high frequency circuit. Traditional FR-4 can absorb up to 50% moisture, while materials such as PTFE can absorb as little as 2%. That’s why high frequency pcb manufacturers generally choose FR-4 materials first.

- Mobile communication products

- Satellite systems, radio systems

- Military and aerospace

- RF microwave

- High density interconnect and highspeed design applications

Factors affecting high frequency circuit board