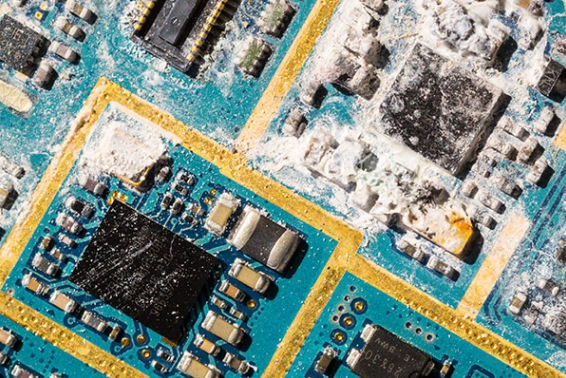

What is pcb corrosion?

Most metals are susceptible to corrosion on circuit board. Of course, the degree of metal corrosion also depends on the metal properties. Some metals corrode quickly, while others never corrode. Here I have listed metals that are highly resistant to corrosion on circuit board, including graphite, gold, silver, and copper-nickel alloys. In contrast, highly corrosive metals include tin, lead, copper, and nickel. Therefore, when producing PCBs, you should choose metals resistant to acid and corrosion to ensure the quality of the PCB.

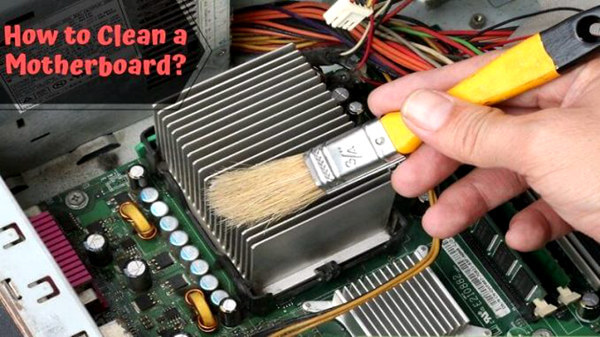

How to Clean up PCB Corrosion

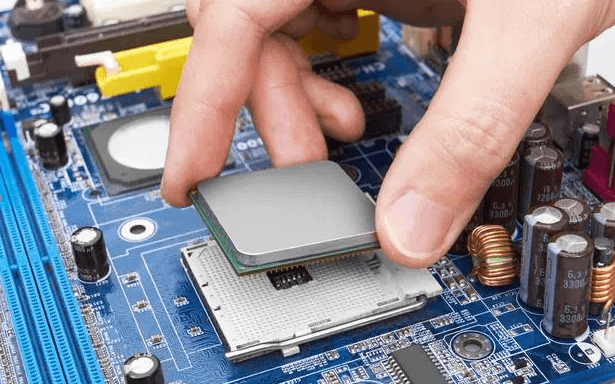

If your printed circuit boards are corroded due to water damage or other causes, cleaning may be a good way to repair pcb corrosion. However, only people with basic electronics knowledge should attempt to clean pcb corrosion. This process of cleaning pcb corrosion involves disassembling the board and avoiding damage to the components. When you separate the PCB from the electronic components, stay away from water and disconnect the device.

You can use various tools to clean pcb corrosion. But do you know the best way to clean pcb corrosion?

Baking Soda:

Baking Soda to clean circuit board corrosion. The alkaline and abrasive properties of baking soda make it the perfect cleaner for corroding PCBs. It is a common reagent for cleaning up corrosion on circuit boards. It will remove and neutralize any corroded areas without causing damage.

Deionized Water:

Deionized Water to clean corroded circuit board. When you use water to clean your pcb corrosion, you must make sure it is free of contaminants. The ions in ordinary water have conductive properties that can degrade the performance of electronics. Meanwhile, deionized water has no impurities or ions that can cause damage.

Household cleaners:

Household cleaners to clean corrosion off circuit board. Phosphate-free household cleaners can help you effectively remove dirt and corrosion. Phosphates protect PCBs from erosion, but they are also a significant source of water contamination.

Soft bristle brushes:

Soft bristle brushes to clean circuit board corrosion. If you don’t have a special PCB cleaning tool, you can use a toothbrush or paintbrush. Brushes with soft bristles will not scratch the delicate parts of the board.

Lint-free towels:

Lint-free towels to clean corrosion on circuit board. Towels made of microfiber and other lint-free fabrics speed up the drying process without leaving particles behind.

Oven:

Oven to clean corrosion off circuit board. A simple home oven will thoroughly dry PCBs when you use indirect heat. But never put a board in the oven without first making sure the stove is turned off.

Tools needed to remove corrosion from circuit boards.

Once you have prepared the chemical solution required to carry out the corrosion removal procedure, you will next need a suitable board removal tool. This includes.

Microfibre cloth or towel

You can use a small towel or a piece of cloth to quickly wipe away any chemicals applied to the board, such as isopropyl alcohol or baking soda. However, make sure that the fabric you use is lint-free, as this will reduce the residue on the board.

Paintbrushes

Small paint brushes with soft bristles also work well to remove rust and corrosion from the board. The bristles must be super soft to avoid leaving any scratches on the board. It is also helpful to reach the tiny gaps in the board for easy, full cleaning.

Hairdryer

Sometimes you may need to dry the printed circuit board because it will not completely remove the liquid from the board. In this case, we strongly recommend using a heat source for this purpose, such as a hairdryer or hairdryer. Alternatively, you can use a desk lamp or a preheated oven.

Which materials on the pcb are prone to corrosion

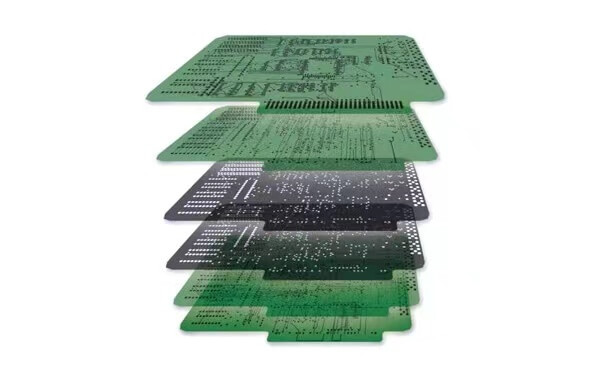

Substrate

Fiberglass board is the core material of pcb. It is a flexible plastic, so it should not corrode no matter what environment it is in. And it helps to prevent damage such as accidental breakage.

Copper foil/flake

The next layer of the PCB substrate is an adhesive-bonded layer of copper foil, which is thermally fixed to the pcb substrate. The most common printed circuit boards have two layers of copper foil, which is a material that does not corrode easily. This is because the copper foil is a highly corrosion-resistant material. It forms a thin, protective, highly adhesive oxide film on the surface. During the bonding process, the prepreg is sandwiched between the epoxy and activated by heat and pressure. The two copper sheets of the pcb are bonded together by the epoxy. This effectively reduces the contact of the copper foil with air and reduces the chances of pcb corrosion.

Solder mask

After the copper foil/copper plate comes, the solder resists layer. Typically, the PCB solder mask is green, but some manufacturers use a different color, such as red. Manufacturers use the solder mask to keep copper traces and pads insulated from other metals, solder, or other pieces of conductive material.

The solder mask is also used to help guide the user by showing them which areas of the board can be soldered and marking the areas that cannot be soldered with green or other colors.

The silkscreen

After applying the solder resist layer, the last layer is the screen printing layer, which is usually white ink. It greatly reduces corrosion on the circuit board.

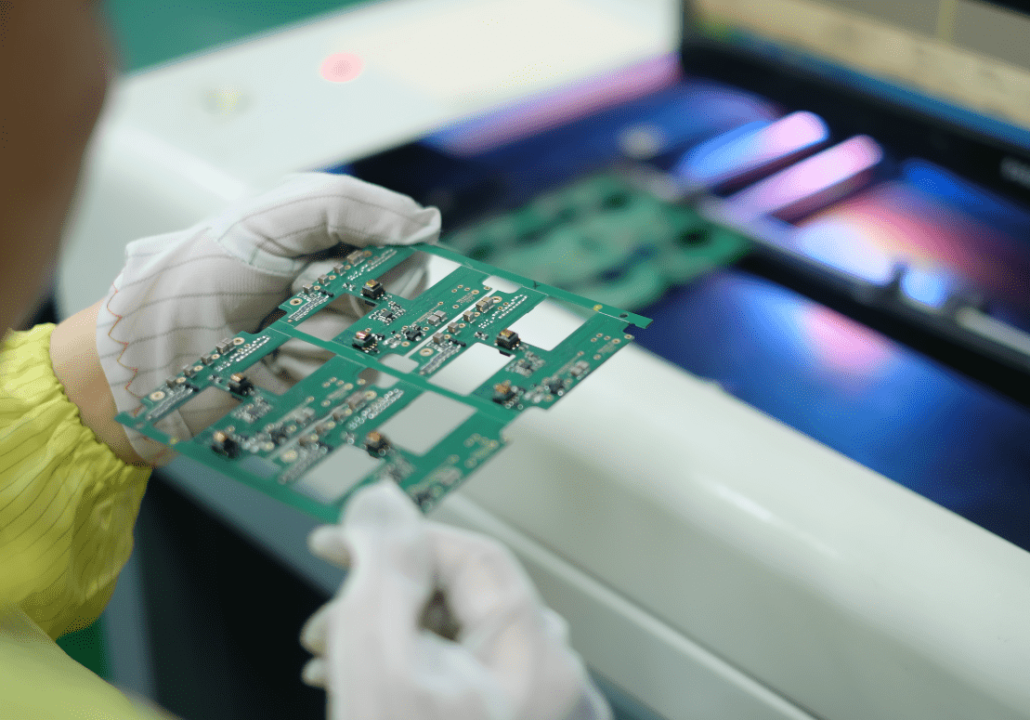

The cleaning process of pcb corrosion

During the production of pcb, some compartments are added to reduce the contact of metal parts with air. This dramatically reduces the chances of corrosion of the metal parts on the pcb. However, in case of improper storage, pcb is still prone to corrosion. For corroded pcb, we usually use a corrosion solution to clean the pcb of the corrosion. This cleans the corrosion off the board.

Pcb etch solutions do usually come configured with ferric chloride and water. Ferric chloride is an earthy solid that rapidly absorbs moisture from the air, so it should be stored in a sealed area. Configuring ferric chloride solutions does generally use 40% ferric chloride and 60% water. Use more ferric chloride in the configuration process or warm water (not hot to prevent the paint from peeling) and make the chemical reaction a little faster. Note that ferric chloride is corrosive, so do not touch your skin or clothing during use, and use a cheap plastic tub for the reaction container.

Clean-up should start at the edges of the corroded PCB board. This prevents the paint from flaking off or corroding the useful circuitry during the cleaning process. When the cleaning is complete, rinse it off with clean water. Incidentally, scrape off the paint with an object such as bamboo (at this point, the color comes from the liquid and is easier to remove). If it doesn’t scrape off easily, rinse with hot water. Then wipe dry and wipe clean with sandpaper to reveal the shiny copper foil, and a corroded printed circuit board is cleaned up. To preserve the results, we usually apply a rosin solution to the polished PCB board to help with soldering and prevent oxidation.

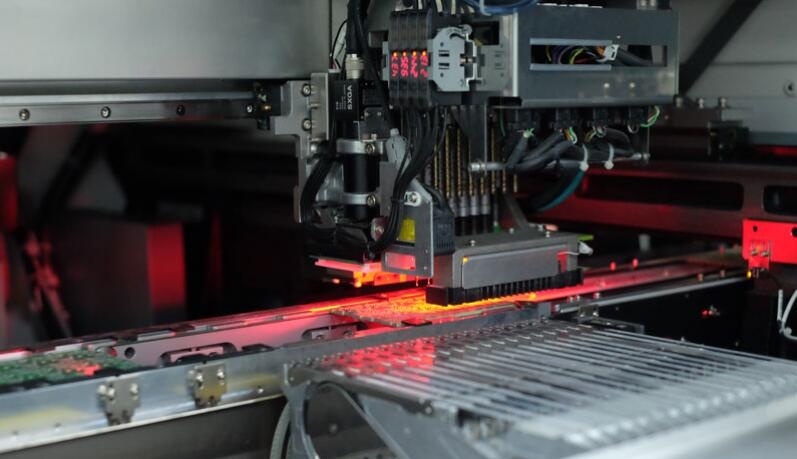

How to prevent pcb corrosion

PCBs contain bare copper and are susceptible to oxidation and other contaminants that can disrupt functionality and shorten the life of the board. While this is not a common topic in circuit board development, several anti-corrosion techniques can protect against it.

Adding a blocking layer

This is a key production step for pcb’s. This process should be done using a desiccant to reduce the exposure of the pcb to air during production. And choose the right solder resist to prevent pcb corrosion from occurring. as the solder resist is the protective element in the circuit board. Selecting the right solder resist layer according to the design of the pcb can effectively protect the board.

The choice of mesh copper sheeting is made to prevent moisture from moving between the layers of the pcb.

After the pcb has been fabricated, a special coating can optionally be applied to its surface. This allows the finished pcb to exist in a more acidic environment, ideal for high temperature environments.

The pcb can then be microencapsulated, which is the most common method of protection for parts or components that are susceptible to corrosion. Finally, it should be noted that while finished pcb does provide protection against corrosion in many ways. However, it is important not to deliberately expose pcb to high temperatures and acidic environments.