It’s a tough job for OEMs to settle on a long-term PCB fabricator or assembler (we’ll call them PCB Houses in the following paragraphs) since the globe is flooded with too many PCB services providers. This article brings some guidelines on how to picking up the perfect fit PCB Houses from your long waiting list. In addition, a FREE template investigation list will be supplied so that you can directly make use of it as a standard when you evaluate a PCB House to build long-term cooperation.

Though PCB manufacturing and assembly contain so many links that should be carefully inspected one by one, the process mainly centers on Products, Capabilities and Service. As a result, this article follows the same route.

Products

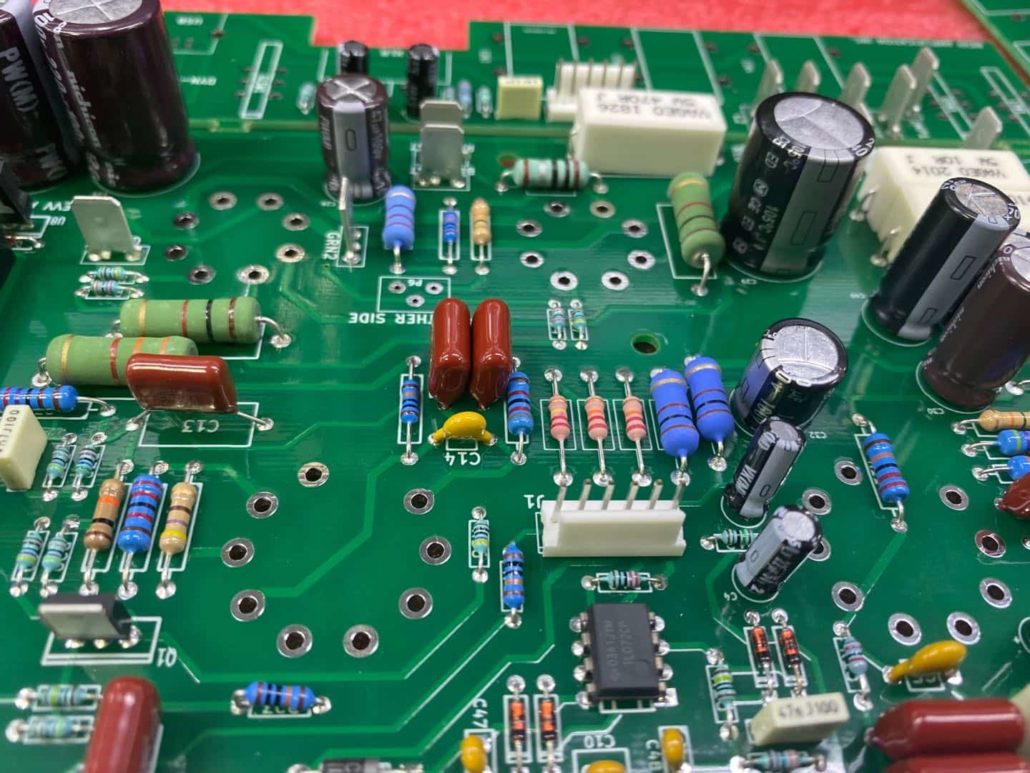

The quality of printed circuit boards will directly affect your final products’ application and performance. Hence, the priority principle of evaluating PCB Houses is to check their products situation, which can be expanded in three aspects: Quality, Industries and Cost.

1). Quality

Everyone is eager for high quality deriving from the following aspects:

• Whether SPC such as Cpk control of components or manufacturing administration diagram has been applied during PCB manufacturing process;

• Whether constant quality administration improvement such as QCC or TQM has been implemented;

• Whether Administration of ECO (Engineering Change Order) is applied;

• Whether there’s component waive control principles published in their terms and conditions;

• Do they conform to stringent quality control evaluations including Material inspection record and administration, SMT yield rate, AQL level, File administration, BOM preservation, ESD implementation, Equipment calibration;

2). Industries

Printed circuit boards are applied in so many different industries, specific industry has strict and special requirements on its manufacturing standards. It’s almost impossible for one PCB House to cover all industries evenly. Generally, they tend to be more proficient in serving certain industries while not so excellent for other industries. For example, PCB Houses proficient in processing PCBs for mobile phones surely have sufficient experience to constrain space in end products, PCB Houses mainly serving for space industries perform definitely better in high density.

Under this condition, you have to be fully aware of industries your investigated PCB Houses good at dealing with so that you’ll cooperate with a professional partner instead of a cure-all partner.

3). Cost

In spite of tips leading to cost reduction in PCB assembly, prices are sometimes a major element driving our final decision. As a necessary consideration when selecting a PCB House, cost should be analyzed from two aspects:

• Integral quotation – Do not be addicted in the attractive figure alone. Reliable PCB Houses are responsible in each word they claim. You should make sure the price their salesperson gives you is a complete price without any hidden or extra money in the later period of your order;

• Constant cost reduction – It refers to some discounts in your reorders. Although a PCB House will never provide you with always-low prices, you can expect a constant discount in your reorder such as free from tooling cost etc. This strategy is the solid foundation for a long-term cooperation;

Capabilities

As mentioned above, product quality is the soul for a PCB House who depends on its capabilities. PCB manufacturing and assembly capabilities can be displayed in the following aspects:

1). Certificates

Certificates stand for the House’s genuine manufacturing capabilities. When cooperating with PCB Houses certificated with ISO9001:2008, UL, RoHS, etc. standards, you can rest assured that they will strictly stick to the regulations of those certificates to obtain a high quality in their products.

2). Technology

Aspects concerning an investigated PCB House’s technology can be summarized into the following items:

• Whether technology it applies caters to your requirement and processing capabilities reach your requirement;

• Whether advancing equipment for processing or automation is owned in their house;

• Whether they perform creatively on technologies;

• Whether it is capable of leading in new processing method in the market;

• Processing capability evaluation;

• BGA IC repair capability;

• Soldering capability of 0201 or 01005 and repair capability;

• RoHS implementing capabilities;

• SOP integrity;

• How to set back mistaken material selection and negative polarity;

• Capability of reviewing circuit and providing DFM service;

• Moisture Sensitivity Level (MSL) component control capabilities;

• Solder paste temperature returning, sealing off and storage life administration capabilities;

• De-panel processing capabilities;