As today’s electronic designs become more advanced and complex, more and more engineers rely on surface mount technology. The technology is now the PCB assembly technology of choice for many smt assembly manufacturers.

Whether it’s medical, military, aerospace, or other fields – it’s all likely to be manufactured through surface mount technology (SMT).

So, what is SMT assembly, and why create this technology?

Article Table of Contents

What is SMT assembly?

Advantages of SMT assembly:

Disadvantages of prototype smt assembly technology:

Application of pcb smt assembly

Basic Processes of SMT assembly:

Mixed Assembly Technology

Advantages of UETPCB’s SMT Assembly Services?

What is SMT assembly?

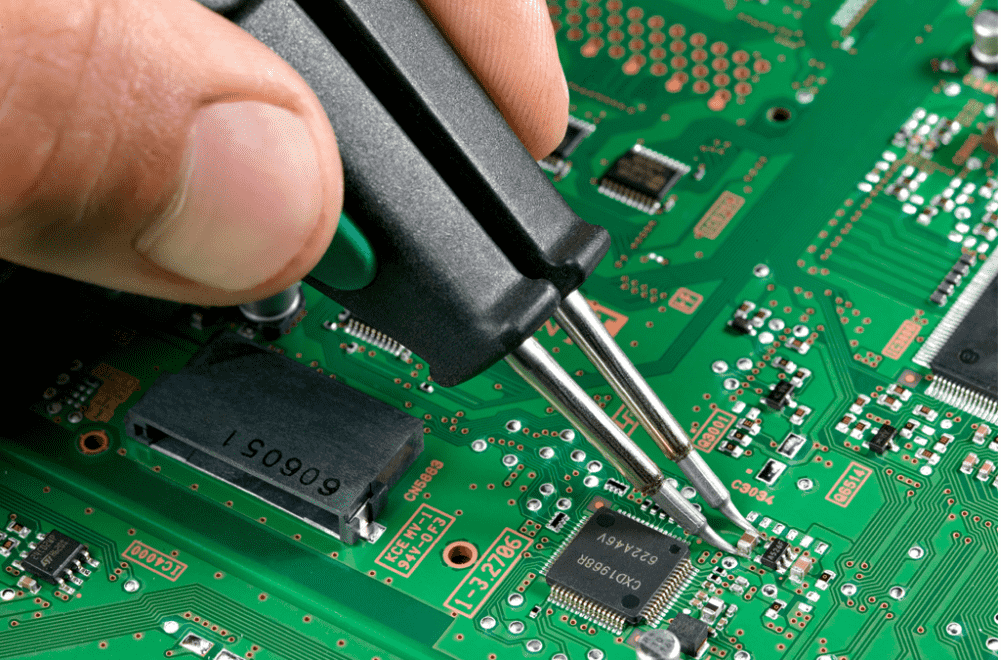

SMT assembly refers to a series of processes on the basis of A PCB (Printed Circuit Board), which is a Printed Circuit Board. SMT is the abbreviation for Surface Mounted Technology, the most popular Technology and process in the electronic assembly industry.

Electronic circuit Surface Mount Technology (SMT) is called Surface Mount or Surface Mount Technology. It is a kind of Circuit assembly technology that installs leadless or short lead surface assembly components (SMC/SMD) on the surface of the Printed Circuit Board (PCB) or other substrate surface and then assembles by means of reflow soldering or dip soldering.

In general, the electronic products we use are made of PCB plus various capacitors, resistors, and other electronic components according to the circuit design. So all kinds of electrical appliances need various SMT chip processing technology to process.

Electronic products pursue miniaturization, previously used perforated plug-in components can not be reduced. Electronic products are more functional, the use of integrated circuits (IC) no longer perforated components, especially large-scale, highly integrated IC, have to use SMD parts. Batch Production, automation production, manufacturers to low cost high output, produce quality products to meet customer demand and strengthen the market competitiveness of the development of electronic components, integrated circuit (IC) development, semiconductor materials for multiple applications. The revolution of electronic science and technology is imperative to follow the international trend.

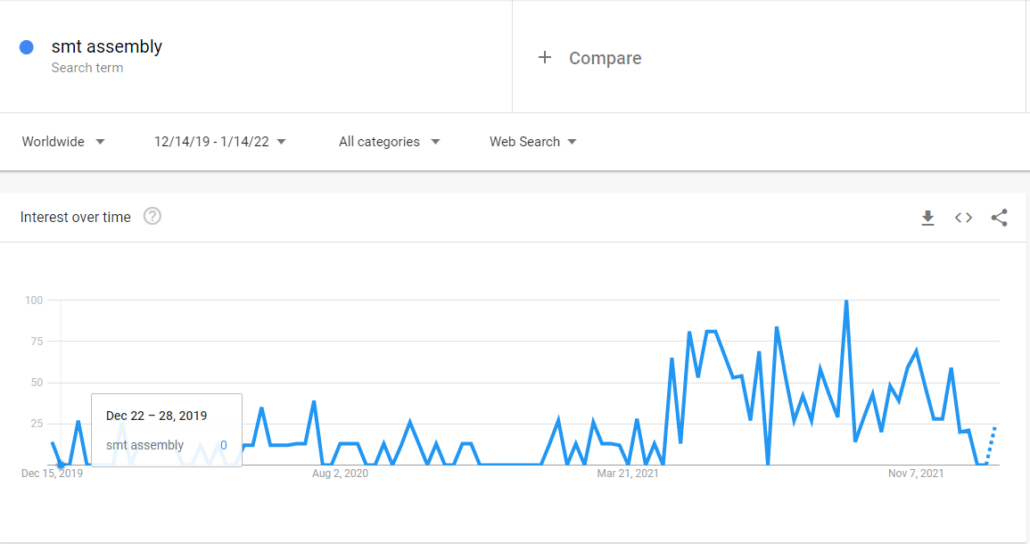

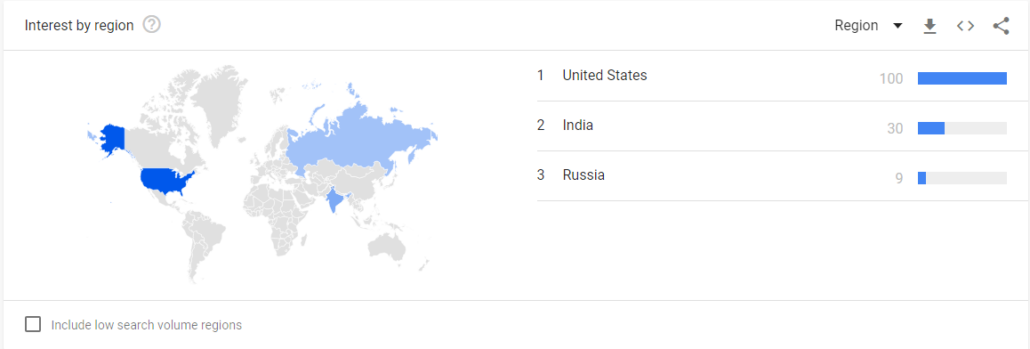

Above is the data from Google Trends, we can see that smt assembly has been growing in popularity from 2019 to today.

The common terminology

| SMD | Surface-mount devices (active, passive and electromechanical components) |

| SMT | Surface-mount technology (assembling and mounting technology) |

| SMA | Surface-mount assembly (module assembled with SMT) |

| SMC | Surface-mount components (components for SMT) |

| SMP | Surface-mount packages (SMD case forms) |

| SME | Surface-mount equipment (SMT assembling machines) |

Advantages of SMT assembly:

Small size and light weight of electronic products are two main advantages of smt assembly. Smt circuit board assembly is a high density assembly that allows products to be more compact and lighter. Due to the booming electronics industry, SMT assembly has achieved an industry boom. Because of the complexity of the SMT chip processing process, many SMT assembly factories have emerged. Like us at UETPCB, we provide our customers with 15 years of experience in advanced PCB assembly technology. From prototyping, small batch to high volume global manufacturing.

Small volume and light weight

The volume and weight of SMT components are only about 1/10 of standard plug-in features. After the general use of smt assembly, the volume of electronic products is reduced by 40% to 60%, and the weight is reduced by 60% to 80%. Rapid smt assembly has high reliability, high vibration resistance, good high-frequency performance, and reduced interference by electromagnetic and radiofrequency. SMT assembly is easy to automate, improve production efficiency, and reduce costs by 30% to 50%. So smt circuit board assembly can save material, energy, equipment, workforce, time, etc.

Fast circuit speed

Many smt assembly manufacturers consider this the most significant advantage.

Component placement auto-correction

The solder surface tension of the pcb smt assembly process can force components to align with the pads.

Low cost

smaller size SMDs or assemblies cost less than larger through-hole versions.

Stability

Better performance delivery through vibration/vibration mechanical conditions. SMT connections are more reliable.

Disadvantages of prototype smt assembly technology.

Probably the most significant disadvantage is that the soldered connections of SMDs can damage by thermal cycling during operation. Once the smt assembly has a damaged component, you will need to purchase expensive tools to repair it again. The price of this repair may be higher than the pcb smt assembly itself.

Most SMT assemblies have smaller dimensions, lead space, and through holes. This makes it challenging to identify components during prototyping and repair or rework.

You use less solder in SMT for solder joints, so the reliability of the solder joint becomes an issue. The formation of voids can cause solder joints to fail here.

Application of pcb smt assembly

We understand the advantages and disadvantages of smt assembly. We know that SMT is not suitable in all cases. So in what situation would we be better off choosing smt group?

As a general rule, SMT can consider the following conditions:

- High density components need accommodating.

- It needs to be light in mass or small in size.

- There is a requirement for high speed/frequency functionality for electronic devices.

- High volume production is performed.

- When your product requires noise reduction

Basic Processes of SMT assembly:

1. Solder Paste Printing

The solder paste printer can design to apply solder paste (a paste of small grains of solder mixed with flux) using a stencil and squeegees to the appropriate pads on the boards.

2. Parts Mounting

Its function is to install surface assembly components accurately to the fixed position of the PCB. The equipment used is an SMT placement machine, located behind the solder paste machine in THE SMT production line.

3. Reflow Soldering

The function of reflow soldering is to melt the solder paste and make the surface assembly components firmly adhere to the PCB board. The equipment used is a reflow soldering furnace, located in the SMT production line behind the SMT placement machine.

4. Inspection

Its function is to inspect the soldering quality and assembly quality of assembled PCB. The equipment used includes a magnifying glass, microscope, on-line testing instrument (ICT), flying needle testing, automatic optical testing (AOI), X-ray testing system, functional testing instrument, etc. Can configure the location in the appropriate part of the production line according to the requirements of the inspection.

5. Repair

It is used to rework the PCB that has been detected to be out of order. The tools used are soldering irons, repair workstations, etc. Can configure it anywhere in the production line.

6. Cleaning

The function is to remove the soldering residue such as flux on the assembled PCB that is harmful to the human body.

Mixed Assembly Technology

1. Single Side Mixed Assembly: In this type, SMDs and through-hole clouds (THCs) are mounted on one side of the PCB.

2. One Side SMT & One Side THT: THCs are mounted on one side while only SMDs on the other side.

3. Double Side Mixed Assembly: In terms of double side mixed assembly methods, there are two alternatives: PCBA with an application of adhesives and PCBA without. The application of adhesives increases the overall cost of PCB assembly. Moreover, during this PCBA process, heating has to be carried out three times, which tends to lead to low efficiency.

Advantages of UETPCB’s SMT Assembly Services?

*Faster Quotes:

We offer 24hours quotes for your turnkey PCB assembly order

*Shorter Lead Time:

Our full turnkey PCB assembly is a highly-efficient and fast form of electronic assembly. You don’t need to worry about managing multiple vendors from PCB fabrication, components procurement, and PCB assembly. With our turnkey PCB assembly services, you can build and refine prototypes and fabrication faster, easier, and more effectively.

*Lower Cost:

Our full-turnkey PCB assembly service is an overall cost reduction. We are experienced electronic assemblers who are able to get reliable components at a relatively low cost based on our long-term cooperation with parts manufacturers or distributors. With end-to-end solutions from a single provider, you can gain significant cost savings, too.

*Better quality control:

We have advanced equipment with 6 automated lines and a team of highly qualified staff who are experienced in working on turn-key circuit board assembly. They not only help meet your expectation in terms of quality, but also complete your projects faster.

UETPCB offers you all the advantages of turnkey PCB Assembly with fast turnaround times and an affordable budget. Our primary mission is to continually provide rapid PCB Assembly services makes us the best choice for your electronic manufacturing. Our products use widely, Automotive, Medical, Consumer Electronics, Aerospace, Digital Communications, Industrial Control and more. It is no exaggeration to say that we are the best smt assembly company in China.