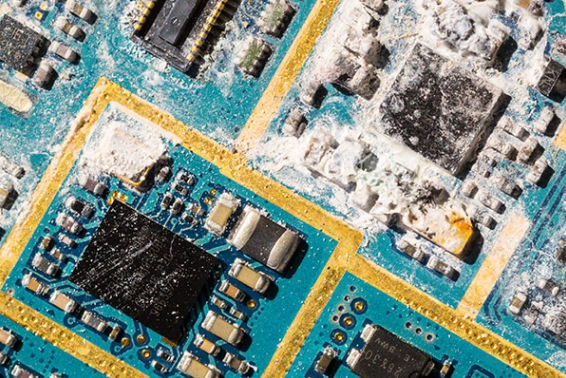

Using cleaners to clean printed circuit boards reduces the waste of resources. Long-used circuit boards can become dirty or corroded due to the environment or improper storage. Cleaning a circuit board is difficult and time-consuming, as its components should be kept intact during cleaning. So many service industries can professionally clean pcb’s. If we want to clean them ourselves, we can do it. Next, we will learn how to clean the circuit board by ourselves.

How to use pcb cleaner to Clean PCBs

We can use effective cleaning PCB methods, which can be better for solving the problem. For example:

- Compressed air

- Baking soda

- Eraser

- Isopropyl alcohol

- Distilled water

- PCB cleaner

Tools for cleaning printed circuit boards

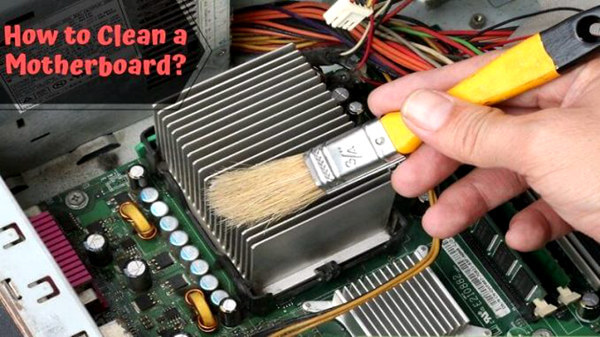

- Brush: We try to choose a meeting with soft and small hair

- Towel: try to choose a super soft fiber cloth that does not shed hair

- Oven: the use of automatic heating can not be used to prevent the drying process occurs during the heating generated by the explosion

Manual cleaning

For just the presence of dust pcb cleaning, we need to prepare a soft brush yourself, then gently sweep the pcb surface.

Compressed air cleaning pcb

If we want to clean the dust in the pcb, this is one of the most common methods to clean the dust. However, it may damage important connections, so extra care should be taken when using it.

Baking soda for PCB cleaning

Baking soda or sodium bicarbonate is an effective method for pcb assembly cleaning and is the least harmful to pcb. It is mainly used to remove corrosion and dirt residue from pcb boards. The steps of baking soda for pcb assembly cleaning are as follows.

- Use a quarter cup of baking soda and a small amount of water to make a cleaning solution until the solution is viscous.

- Take pictures of the board configuration for later re-installation

- Disconnect the cables

- Remove any chips from the board

- Dip a brush or towel into the cleaning solution and apply it all over the corroded area

- Wait 15-30 minutes for the baking soda cleaner to start drying

- Rinse the board with distilled water and make sure to remove any remaining dry baking soda

- Spray a phosphate-free cleaning (such Clorox or Lysol) over the entire surface and let it settle for about 15 seconds.

- Gently scrub the board again with a clean toothbrush and rinse well

- Then gently wipe the board with a clean, soft towel

- Preheat the oven to 170 degrees and turn it off. Place the circuit board and let it sit for 3 hours

- Reassemble and test it

Eraser to clean the pcb

If there are still visible signs of corrosion after using baking soda cleaner, we can try to use an eraser to clean the remaining dirt.

Isopropyl alcohol for PCB cleaning

Isopropyl alcohol is a perfect PCB cleaner because it is cheap and evaporates quickly. It is often used in pcb assembly cleaning, but one should note that isopropyl alcohol with a content higher than 90% can be harmful in contact with the body. So be careful or wear protective clothing during use.

Distilled water cleaning PCB(water for cleaning pcb board)

Distilled water does not contain conductive ions, so distilled water is a common solution in pcb cleaning. It should be noted that in the process of using distilled water, try not to contact our limbs to avoid contamination of the solution. Water for cleaning pcb board must be distilled water.

Cleaner cleaning PCB

Use phosphate-free pcb cleaner(pcb cleaner spray). You can also take the help of a benchtop pcb cleaning machine, which works together with a pcb cleaner(pcb cleaner spray).

Ultrasonic PCB cleaning

The ultrasonic pcb cleaning machine uses ultrasonic sound to clean down the dirt on the pcb surface. However, the cleaning process requires constant vibration of the pcb board, which may cause some components or patches to lose. This benchtop pcb cleaning machine is suitable for many pcb cleaning needs.

How to remove the flux on PCB

A heated metal with a low melting point is used to solder two metals together. For soldering, flux is required. The joint is shielded from metal oxides by it. By transforming the metal oxides into salt and water, it achieves this. Of course, removing the solder resist is also a joint operation in pcb cleaning.

But it would help if you did not use reagents with too strong a cleaning effect to avoid damaging the pcb board.

How to use the correct cleaning tools

Brush: The brush and pcb cleaning angle is 45 ° best, from top to bottom. When using the dissolver, one must pay attention to spraying directly to the head of the brush, then slowly scrub the pcb board.

What are the most popular electronic cleaners?

No pcb board cleaner is more widely used in the assembly and maintenance of electronic devices than isopropyl alcohol. It is commonly used for cleaning and as a primary ingredient in fluxes, but how much do you know about isopropyl alcohol?

IPA, isopropyl alcohol, 2-propanol, and even topical alcohol are other names for isopropyl alcohol (CAS #67-63-0). It dissolves a variety of polar and non-polar dirt. It is commonly used to dissolve and remove fingerprints, light oils, flux residues, cutting fluids, carbon buildup, and mold release.

Lsopropyl alcohol is used to clear flux residue from recently soldered boards or PCB repair and rework for electronic printed circuit board (PCB) construction. Ipa is also used to clean SMT stencils of solder paste or glue.

Conclusion

Some companies specialize in PCB cleaning. Please note that we do not offer PCB cleaning services! We are a high-end supplier for PCB manufacturing and assembly. Our engineers will recommend the best solution for you. You can also come to us if you have questions about cleaning your circuit boards.