Long before printed circuit boards (PCBs) appeared in films. There were already vacuum tubes performing a similar function. At the simplest terms, PCBs are utilized for linking components in electronic goods in a hassle-free and more economical manner.

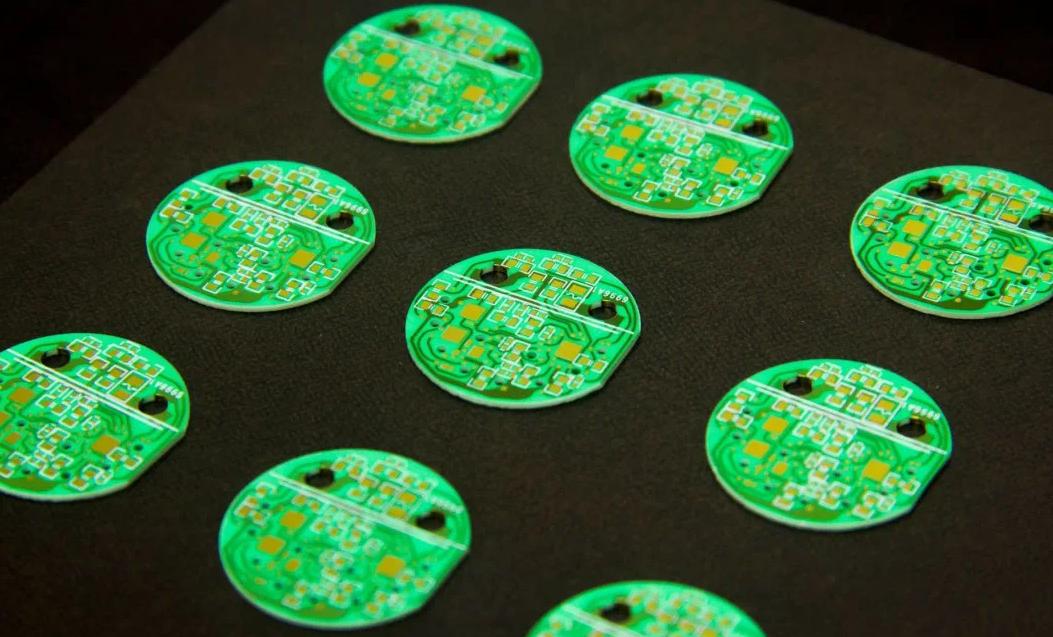

Typically, PCBs are made of insulating material. Pcb’s are coated with metal, either on the bottom of the top. If you find a conventional printed circuit board (PCB manufacture), you will find etching on the outside. In PCB manufacturing, this can be made with acid to produce a path for the power supply. Etching in PCB manufacturing ensures that the different elements work in sync with each other as planned. These elements are then soldered to the surface to become the final product. With this quick shortcut, it’s easy to see why PCBs are so powerful and important in the electronics field. Here are a few other aspects of PCB manufacturing that you will want to know about.

The Benefits

Well, PCBs have made it feasible to have smaller and compact digital circuits. Now, you’ll discover a PCB manufacturing in virtually every gadget. From the computer, the motherboard is the primary printed circuit board. Additionally, there are additional holes and holes on particular circuit boards, which are meant for utilizing different elements, such as capacitors.

The Greatest Materials

Producers usually provide their materials from famous providers, for example Rogers. Rogers’s substances are famous for microwave functionality and are compatible with FR-4 manufacturing. These have high thermal conductivity, which works wonders for both thermal controls as compared to a number of those additional PTFE substances which are used traditionally.

Obtaining Printed Circuit Board Prototypes

Ordinarily, businesses and electronic brands do not purchase one PCB manufacturing. They’ve a huge order, and therefore to be produced, a prototype is necessary. A PCB model is the primary one that is created and analyzed in any way levels to make sure the planned functionalities and benefits are attained. There are producers who possess the essential experience and expertise to acquire a printed circuit board prototype completed in under a week. When the model is completed, analyzed, and accepted by the customer, the exact same is subsequently sent for creation. The generated printed circuit boards will be in sync with the pcb manufacturing requirements but are often tested separately prior to dispatch.

Locating a Seller

In case you require fast turn PCB, locate a pcb manufacturing company with the infrastructure and abilities to get the work done in a predetermined time. It’s crucial to make certain that the maker has expertise of at least a decade in the business. You might wish to understand their customers, and as desired, request some references also. It’s also sensible to test if the worried PCB maker can design the model in a brief interval as needed. It’s almost always best to utilize famous names since you don’t need to bother about the quality, time, and shipping along with all of the other pertinent elements. Get a quote in progress however.

From design to production, greatly shorten customer R&D cycle. The fastest expedited PCB prototype service can provide 24 hours delivery for 2layers, 48 hours delivery for 4 layers. Our PCB products are widely used in consumer electronics, medical equipment, industrial control, automotive manufacturing and other fields. Professional in all kinds of high difficulty, high precision and density circuit board.