If you deal with electronics, you may have heard the words printed circuit board (PCB) and printed circuit board assembly (PCBA). Even though these phrases are often used interchangeably, they do not always signify the same thing.

So, what are these things have in common? Moreover, what is the difference between a printed circuit board and a PCBA circuit board?

Printed circuit board (PCB)

Electronic components may be attached to a PCB to form a circuit by mounting them on the mechanical base. An epoxy resin-coated glass substrate serves as the PCB’s conductive pattern or trace.

Printed circuit boards (PCBs), as the name implies, are made up of printed components or printed circuit boards (PCBs). Four and six-layer PCBs are the most popular. However, a bare PCB may be split into as many as eight signal layers. According to the established design, the epoxy glass is either printed or etched with a conductive pattern.

What is the purpose of a printed circuit board (PCB)?

It is possible to design and manufacture a PCB that may be used in various electronic devices such as televisions, radios, mobile phones, and computers. PCBs are also useful in manufacturing lighting equipment, medical equipment, automobiles, and most industrial machinery.

Electronic components are supported by the PCB, which acts as an electrical link between them. The following is a list of PCB’s distinguishing characteristics:

- high-density wiring is appropriate for the downsizing of the electronic equipment in issue because of its low weight and tiny size

- Because of PBC’s visual consistency and repeatability, it is feasible to save time and money on the maintenance, troubleshooting, and inspection of electronic equipment.

Common Types of PCB on the Market

Single Layer PCB

A single-sided printed circuit board (PCB), often known as a single-sided PCB, is the most popular PCB because it is straightforward to design and fabricate. Conductive material, such as copper, is used to cover the single-layer PCB. PCB oxidation is prevented by applying a layer of solder mask. A silkscreen identifies printed circuit board components. Printers, radios, and calculators are all examples of products that employ this sort of PCB.

Double Layer PCB

Often referred to as a double-sided PCB, this board contains a layer of conducting material applied to the top and bottom surfaces. One of the key advantages of this PCB over its single-sided predecessor is that it is more flexible and smaller. It is utilized in industrial control systems, UPS systems, phones, converters, amplifiers, power monitoring devices, and HVAC applications.

Multi-layer printed circuit boards (PCBs)

This kind of PCB has more than two copper conductors. As a precaution, glue is sandwiched between insulations to prevent the circuit from being destroyed by overheating. Satellite systems, GPS technology, file servers, data storage devices, and medical equipment are all examples of its utilization.

Rigid PCB

A Rigid Circuit Board is a PCB that can’t be bent or twisted. It doesn’t have a lot of wiggle room. One-sided, double-sided, or multilayer rigid PWBs are all possible. Rigid Circuit Boards cannot be altered or folded into any other form once they are produced.

Flexible Printed Circuit Board (FlexPCB)

“Flexi Circuits” or “Flexible PCB” is another name for “Flex PCB.” These PCBs are simple to handle and move because of their flexible material and form. A Flex PCB can be either a single-sided or double-sided PCB. As the name indicates, Flex PCBs may be folded and are not as rigid PCBs are.

Flexible plastic (a thin insulating polymer sheet), polyimide, or a similar polymer, or Kapton, is the substrate of a flexible board.

This substrate is printed with a conductive copper circuit, and a thin polymer coating is added to protect the circuits. In the copper tracks, there are many components. Most of the time, SMD Com

PCB Applications

- PCBs may be used for consumer electronics to heavy industrial robots to automotive components, and medical devices. It exists on:

- Computers

- Printers

- Televisions

- Cell phones

- Radios

- Appliances

- Calculators

- Medical imaging systems

- Lighting systems

- Industrial controls

- Pacemakers

- Data storage devices

- Engine management systems

- Telecom towers

- Satellite systems

Printed Circuit Board Assembly (PCBA)

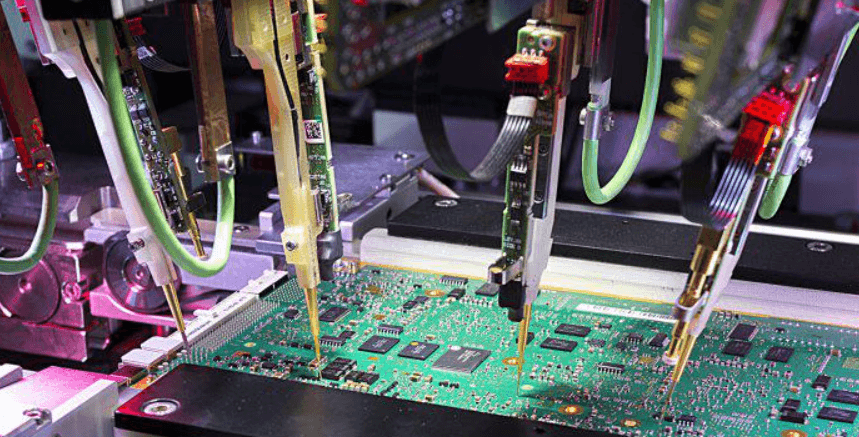

Printed circuit board +assembly, PCBA, is the whole process in which the unpopulated PCB board is passed via the PTH and surface-mounting technology procedures. Solder paste printing and component placement are two of the many techniques used to assemble the blank PCB board with all the electrical components attached to it.

PCBA Components

To create a working printed circuit assembly (PCA), electrical components are inserted onto an empty PCB board during the PCBA manufacturing process. The electrical parts are installed in holes surrounded by conductive pads using through-hole technology.

Components are mounted on the PCB using SMT to guarantee that the pins align with the board’s conductive pads. Applying glue before connecting elements attached to one side of a printed circuit board (PCB) is necessary.

One of the following methods may be used to test a PCBA board:

- An automated optical inspection instrument while the power is turned off.

- Analog signature analysis while the power is turned off.

- Circuit tests are carried out when the electricity is on.

- Finally, a functional test may be performed to see whether the PCB performs what it was supposed to accomplish.

Through-Hole Innovation

Drilling holes into a printed circuit board (PCB) allows electrical components known as leads to be connected. It’s an older PCB assembly method than surface-mount PCBA technology.

Automated or semi-automated through-hole assembly may be used for several purposes. Still, it provides a more secure bond between the board and the components, making the final product more dependable and long-lasting. The PCBA through-hole procedure includes the following steps:

- Drilling holes in the board is the first stage in the thru-hole procedure. These holes must be of the correct diameter to accommodate the component leads.

- The next step is to insert the leads into the holes.

- The next step is soldering, and this is the last step. As a result of this procedure, all of the components are kept in place.

To guarantee that the PCBA functions as planned, the assembly is inspected throughout the process.

What Makes PCB and PCB Different

Printed circuit board (PCB) and printed circuit board assembly (PCBA) are identical terminology in the electronics industry. In reality, these are two separate entities that people often confuse.

For the most part, PCB and PCBA are interchangeable terminologies. However, the PCB refers to an unassembled circuit board, while the PCBA relates to an assembled circuit board.

- In contrast to a PCB, a PCBA is a fully working board since it has all of the necessary components in place. It is important to note that PCBs and PCBAs are two distinct elements of the same PCB board manufacturing

- The PCB and PCBA are two different products of the same general approach. In contrast to a PCB, a PCBA is a fully assembled circuit board that includes all components necessary to perform appropriately in the intended application.

- Unlike a PCB, a PCBA may be employed in an electrical device immediately. It is easier to produce a blank PCB than a fully assembled PCB because of the many components and procedures.

- PCBAs are also more expensive to make than blank PCBs. A finished board, however, requires both stages. Without a printed circuit board, you cannot build a PCB.

- Conventional printed circuit board fabrication (PCB) manufacture begins with this initial stage, and PCBA productionmakes it.

- The packaging of PCBs and PCBAs is another difference. There are two types of packaging used for PCBs and PCBAs: vacuum packaging and compartmental or anti-static packing.

- A PCBA is a pre-assembled system that includes all essential components and is ready to be used. For example, capacitors, resistors, diodes, triodes, and many more components may be used in PCB construction. PCBA is a complete electronic assembly, while a PCB is only the electrical circuitry on a raw board.

Is It Always Cheaper To Buy PCBAs In China?

In a nutshell, yes, PCBA is less expensive in China. Allow me to provide you with some examples to help you understand.

A PCB assembly manufacturer in Germany will charge you US$ 339 for 30 two-layer boards with dimensions of 80x90mm. In China, similar devices with the same features would set you back $20.

In addition, Chinese PCB Assembly services offer turnaround times of one week or less. For a 1k unit order, a USA PCBA will have a month turnaround time and a unit price of US$3.48 per unit. A similar order to a Chinese PCBA would cost US$0.37 per unit and take five days to complete.

PCBA and PCB service in China is cheaper and quicker most of the time, even when import times are included in.

Final Thoughts

Because electronic parts are not easy to handle, specialists in this sector must constantly learn and improve themselves. However, terminology like PCB and Printed Circuit Board Assembly is often misunderstood.

It’s important to realize that these two names aren’t equivalent; the PCB refers to a base plate that has been modified. It becomes a PCBA once the essential electronic components are installed on it, and it may now perform a specific electronic function.

At (your company name and link), we provide a one-stop-shop for PCB and PCBA. Please call our sales team at (our phone number) to discuss your needs in further detail.