Our everyday lives are being affected by the rapid expansion of contemporary technologies worldwide. Our way of life has radically changed as a result. This technological growth has resulted in numerous advanced pieces of technology into the globe that we could not have imagined even ten years ago.

The Printed Circuit Boards (PCBs) are at the heart of these devices, and they serve as their nucleus (PCBs).

This guide will take you through the PCB assembly process, from purchasing guide to PCB assembly services to testing your final product.

Introduction to the PCB Assembly

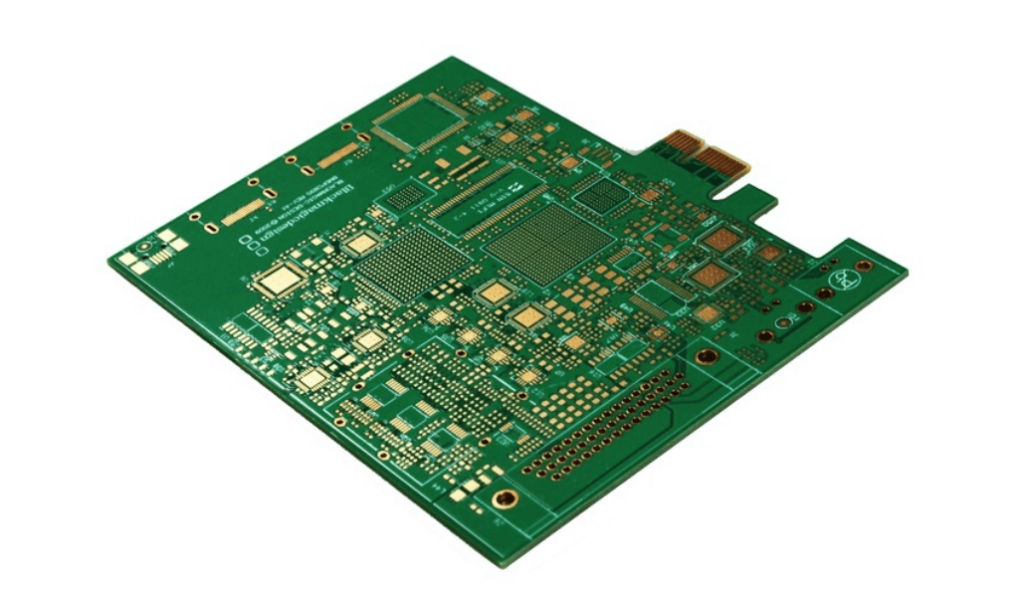

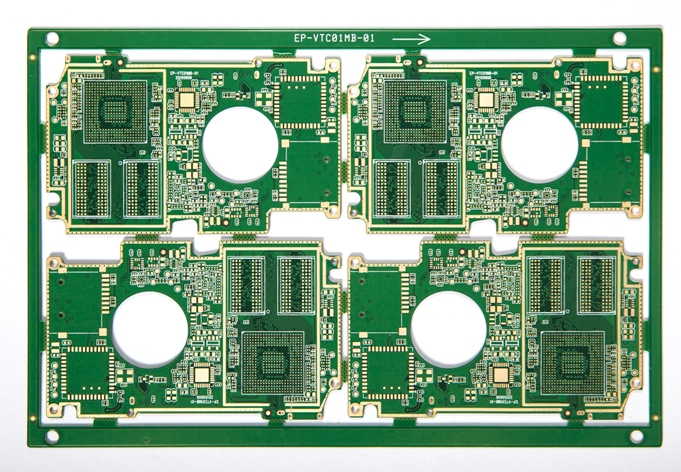

The printed circuit board (PCB) is a rigid body containing various electrical components and is often green in color.

PCB Assembly, known as PCBA, is how these components are soldered onto PCBs. The PCB comprises several layers, including a fiberglass substrate, the elements, and a copper layer that creates the traces.

In addition, it has holes into which the components are placed and among them are inner and outer layers.

Printed circuit boards are employed in various electrical devices, which is especially prevalent in today’s modern culture. It’s no surprise that printed circuit board assembly (PCB assembly) can consider one of the most critical procedures in the electronics industry.

This article is designed to give you basic information on the processes involved in PCB assembly and the equipment used.

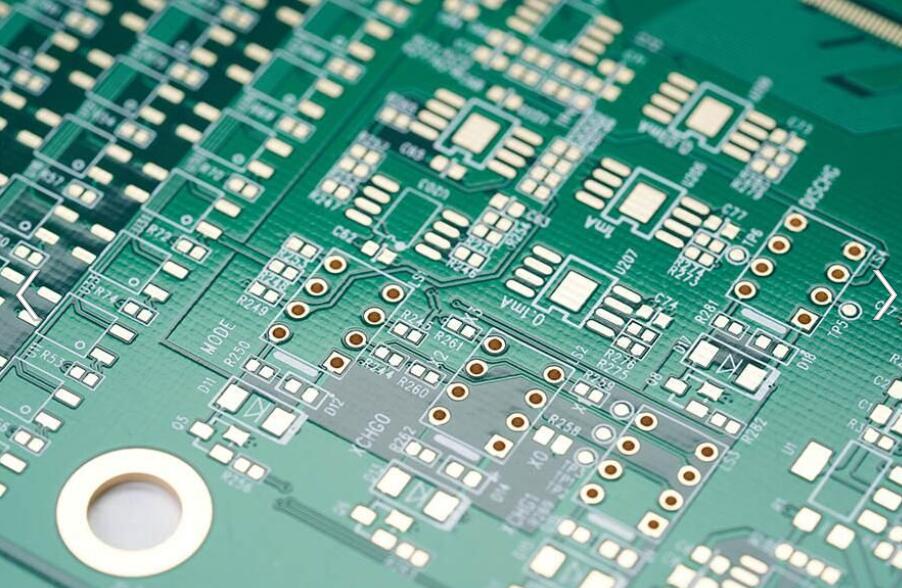

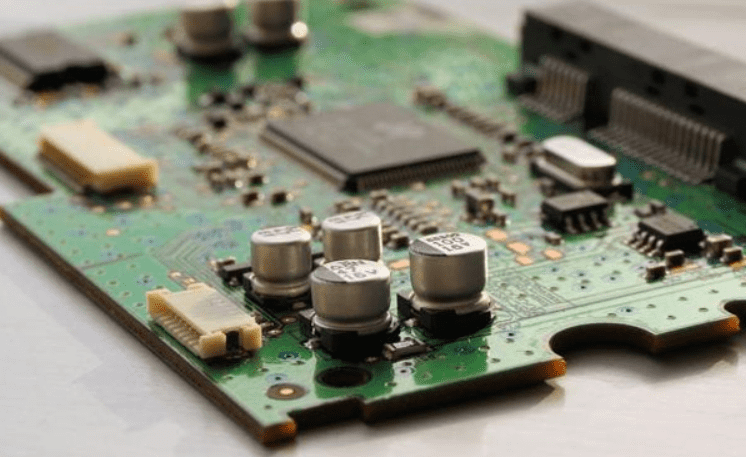

Components and Layers of PCB

Four key components make up a PCB assembly:

1.Substrate:

The substrate is the first and most critical component, and it is often constructed of fiberglass. PCB assembly services utilize fiberglass because it adds structural integrity and prevents the boards from shattering.

2. Copper Layer:

This layer can be either copper foil or a full-on copper covering, depending on the board type. Regardless of whether the method is employed, the copper’s primary function remains the same—to transmit electrical impulses between the PCB and the rest of the circuit board.

3. Solder Mask:

The polymer layer known as solder mask is the third portion of the PCB assembly manufacturing, which helps shield the copper from short-circuiting from environmental contact. The solder mask serves as the PCB’s “skin” in this manner.

4. Silkscreen:

Also known as legend or nomenclature, silkscreen is the last component of the PCB assembly board. In most cases, the silkscreen is utilized to display part numbers and logos, switch settings, component reference, and test locations.

Types of Printed Circuit Boards (PCB)

Printed circuit boards (PCBs) come in a wide variety of shapes, sizes, materials. PCB assembly manufacturers and companies keep in mind the wide range of needs of their customers.

Single Layer PCB

Single-layer printed circuit boards are among the simplest in terms of design and manufacturing complexity that a PCB assembly service provider manufacture. This type of circuit board design has a single layer of conductor material (such as copper) on only one side of a non-conductive substrate.

Double Layer PCB

A conductive layer should place on top of the non-conductive substrate. The other conductive coating is placed on the opposite side, forming a double layer printed circuit board (top and bottom).

MultiLayer PCB

A circuit board with three or more conductive layers is a multilayer board. In addition to the top and bottom conductive layers, another layer can sandwich between two non-conductive substrates. Advanced Circuits can produce boards with a layer count as high as 40. However, the most popular are 4, 6, or 8-layer boards.

High-Density Interconnect (HDI) PCB

High-density integrated circuit (HDI) printed circuit boards (PCBs) utilize precision manufacturing techniques to maximize density while minimizing size. Many conductive layers, laser-drilled tiny holes and lines, and sophisticated laminate materials achieve this effect. Chips with high pin counts and other high-tech miniaturized components can be routed with HDI PCBs’ advanced routing capabilities.

High-Frequency PCB

The most significant difference in producing high-frequency printed circuit boards is design. With these PCBs, you can run signals up to 1 GHz. High-frequency printed circuit boards may necessitate sophisticated laminate materials and regulated impedance, depending on the application.

Why is PCB Assembly Important?

PCBs play an essential part in today’s technology-driven world. Because they are present in virtually every piece of electronic equipment, these circuit boards are the building blocks of the industry.

Compared to other production formats in the same domain.

PCB assembly offers the following significant advantage:

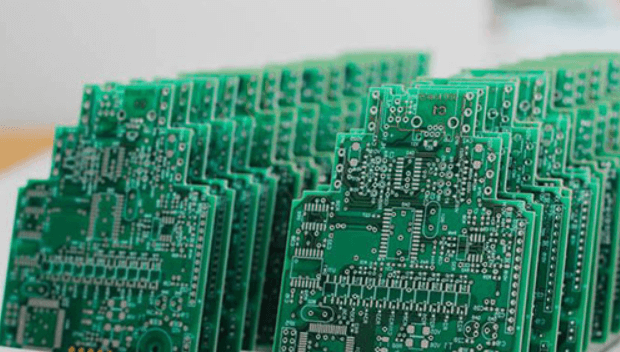

1. Using a PCB Assembly service, you’ll be able to manage a greater volume of orders at once and work in batches. Using a PCB Assembly service can save money and time and minimize unnecessary waste.

2. If you have limited resources, including a Printed Circuit Board (PCB) is easy to increase production. Small-scale producers will benefit greatly from this type of solution.

3. Working with a PCB Assembly service always has the primary benefit of reducing your overall overhead expenses dramatically over time.

4. Small firms have a major difficulty when it comes to operating on the principle of economies of scale. A simple solution is to incorporate PCB Assembly and accept bulk orders.

5. With PCB Assembly, testing and diagnostics are made simple. It is now easier than ever to identify and rectify any production problems using a simple diagnostic test.

6. PCBs are a space-saving technology. PCB assemblies can be as thin as a human hair strand.

Assembly of A PCB Board?

When a customer places an order for a PCB assembly, the PCB assembly companies first develop a PCB assembly prototype keeping in mind the design and needs of the client.

The many steps of the PCB assembly manufacturing include the application of solder paste to the board, selecting and placement of the components, soldering, inspection, and testing.

These steps are necessary and must be managed to ensure that the best quality product is made available.

Stage 1: Solder Paste Stenciling

This phase is the same regardless of the kind of PCB assembly. The board can cover with a stencil produced from a thin metallic sheet. It guarantees that the solder paste can exclusively apply to the area where the components are inserted. The stencil is removed from the circuit board once the solder paste has been used.

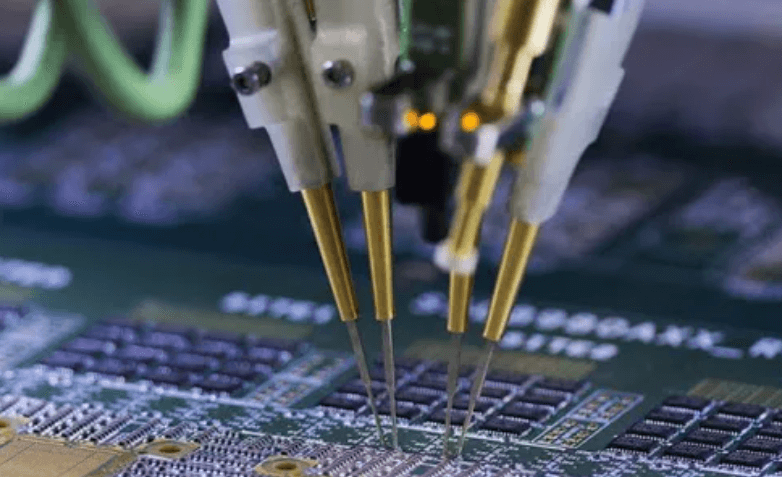

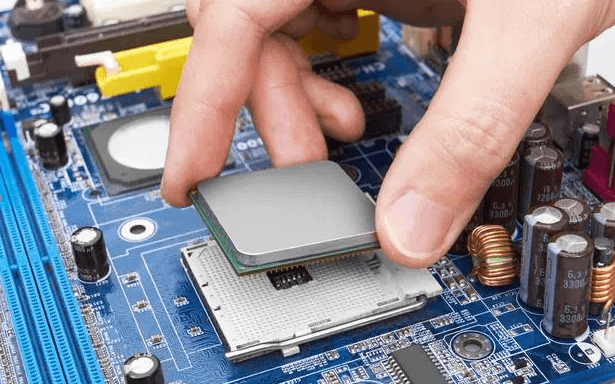

Stage 2: Components Mounting (Pick & Place)

A pick and place operation can conduct manually or mechanically by an automated system for component installation. Components do manually mount during the through-hole PCB construction process. Automated machines can use in surface-mount PCB assembly. Automatic component mounting provides a speedy, precise, and error-free operation.

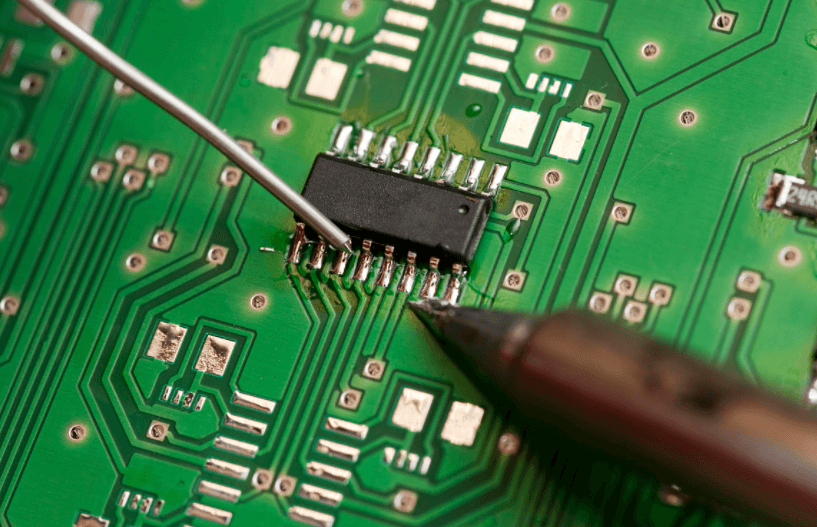

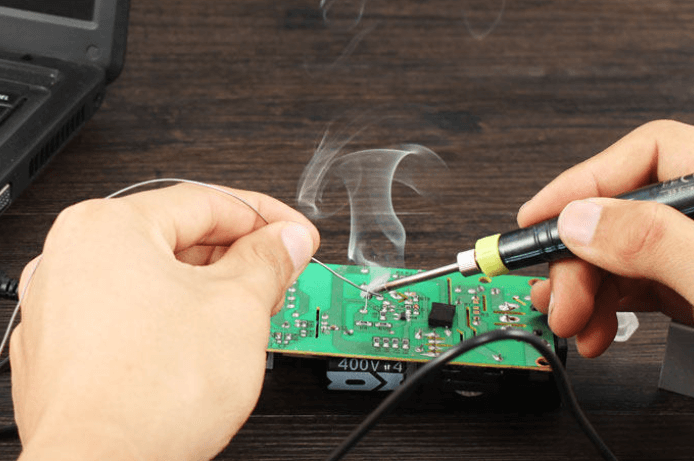

Stage 3: Soldering

Soldering does use to connect components on a printed circuit board (PCB). The wave soldering process does use in the through-hole assembly. On the other hand, Reflow soldering does use in the construction of surface mount PCBs.

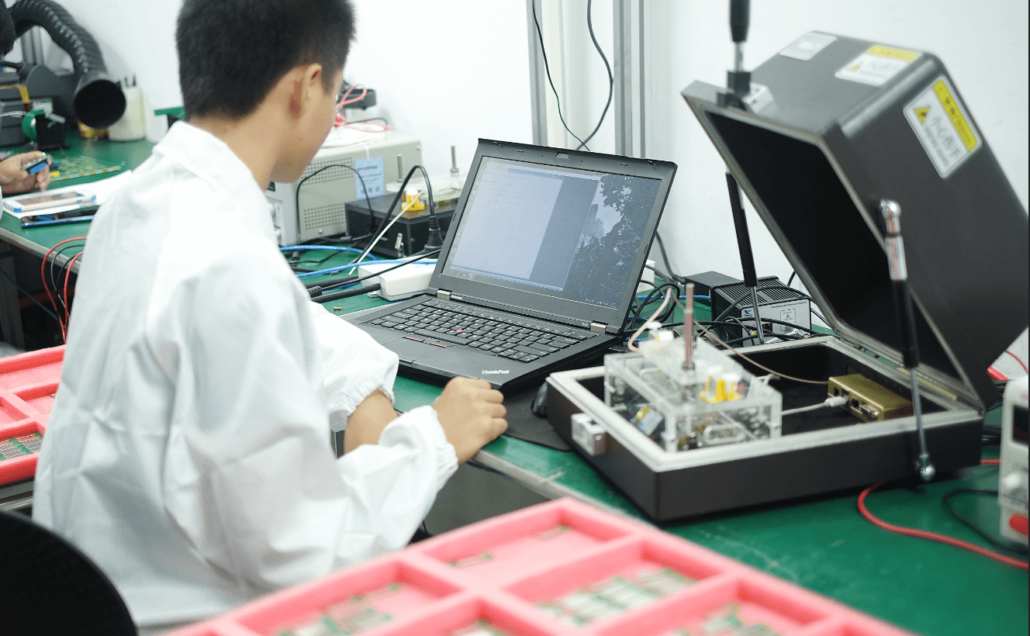

Stage 4: Inspection & Quality Testing

Inspection and quality testing are carried out to guarantee that the equipment is properly working.

Stage 5: Feedback Testing

It is vital for PCB assembly services providers to monitor the outputs of the manufacturing process to guarantee that PCB assembly is working smoothly.

How Do I Order A PCB Assembly?

Union Electronic Technology Limited (UET) is a Chinese PCB assembly manufacturer that has built a reputation as a loyal, dependable, and dedicated member of the printed circuit board industry over many years. We’ve been delivering printed circuit board assembly services to clients worldwide.

As a result of our commitment to precision and quality, customers consistently rank our services as the finest in the industry. Unlike other companies, we build our PCB assembly boards in China to exacting standards.

Our testing services are of the highest caliber.

The materials we utilize are from the most reputable sources in the nation.For all of your printed circuit assembly requirements, we are ready to supply you with a high-quality, one-stop-shop experience right now.

Get a free estimate on PCB board assembly services by filling out the form below with basic information about your project immediately.

Please do not hesitate to contact us if you have any questions concerning PCB assembly costs, our offerings, or our procedures.

Production Time

A specialty of Union Electronic Technology Limited (UET) is the quick turnaround of small to large volume production runs. Our printed circuit board assembly capabilities allow us to promptly handle vast numbers of complicated boards.

We are a PCB assembly manufacturer in China. We are happy to provide an unlimited number of PCB assembly prototypes upon request.UETPCB’s excellent PCB assembly service is closely linked to the expertise and dedication of our staff. Because of the information and abilities we’ve accumulated through the years of development, we’re able to deliver high-quality items consistently.

This commitment to rapid, precise production in every element of our circuit board assembly technique is what distinguishes us as one of the most in-demand PCB SMT assembly companies in the industry.

According to the individual order criteria, PCB manufacture can take 10 to 15 business days. This does not include any delays caused by difficulties with the order/files.

Production Quality

PCB manufacture is not a straightforward endeavor. Printed circuit boards serve as the structural foundation of every electronic gadget now in use. Each day, factories and people use PCBs in their products and machines.

We recognize the importance of ensuring that every board we construct and ship meets customer expectations.

At every stage of the manufacturing process, we submit the boards we manufacture to stringent quality assurance criteria.

Price

The price is dependent on your project, the size of your component, the type of material you desire, the weight, the prototype, the kind of design, and custom packaging and labeling.

Once you have requested a quote for your selected product, we will send you an invoice that you can use to place an order with us.

We provide flexible payment plans to both new and returning clients; if you have any questions about your payment, don’t hesitate to get in touch with our customer service team here.

After Sales Service

Our after-sales service is fantastic, and we provide all of the support and assistance necessary to ensure that our clients have the most outstanding possible experience after purchasing our product.

Our after-sales services involve providing instructions on utilizing our product or service. We are constantly accessible to answer questions and follow up to ensure that our customers are pleased with their purchases.

We wholly dedicate ourselves to ensuring your absolute satisfaction. For any issues with inferior-quality products or services, please contact our sales representative here at your earliest convenience.

Additionally, if you can offer images, it will aid us in our investigation and provide you with answers more quickly. We guarantee that we will address the situation as promptly as possible and within your expectations.

SMD Process

Surface mount devices (SMD) uses PCB SMT assembly machines to make PCB assembly the most convenient alternative for businesses seeking to outsource this process for use in their operations. PCBs are primarily responsible for two critical functions:

- Printed circuit boards used to link the components to one another. They also provide input and output connections, allowing for a seamless user experience with the device.

- PCBs can use to provide mechanical support for a variety of electrical components.

It is critical to decreasing the number of parts, printed circuit boards (PCBs), connections, and other similar components to improve performance while lowering costs in any electrical design. However, the decrease of PCBs frequently results in the employment of more difficult-to-handle materials, increasing the value of the product.

Because of this, selecting the most appropriate PCB assembly service for your application is essential. Here are some of the benefits of using our services:

- Assured expertise

- Service for the management of materials

- Exceptional design quality

- Guaranteed quality assurance

Take Away

There are and numerous PCB assembly companies out in China. Given that printed circuit board assembly (PCB assembly) is such a critical and challenging process for the electronics industry, putting your confidence in the appropriate PCB assembly China manufacturer is essential to having a well-made and functioning product.

Union Electronic Technology Limited dedicate to producing the highest-quality printed circuit boards (PCBs) for your unique application. Along with printed circuit board (PCB) assembly, we provide various other services, such as materials management and testing.

Our materials management service ensures that you receive the highest quality supplies for your printed board design project.

We also recognize the importance of quality. That’s why every printed circuit board (PCB) we make undergoes extensive testing. We do our best to ensure that it performs accurately. We intend to tailor each order to your exact specifications.

So, if you want to do PCB assembly for your company, consider us.