You may have also discovered Halogen Free PCBs when buying or touching a pcbs. So what is a Halogen Free PCB, and what is the difference between it and a standard pcb? You may have many questions, and the following article will briefly introduce Halogen Free PCBs.

What is a halogen free PCB?

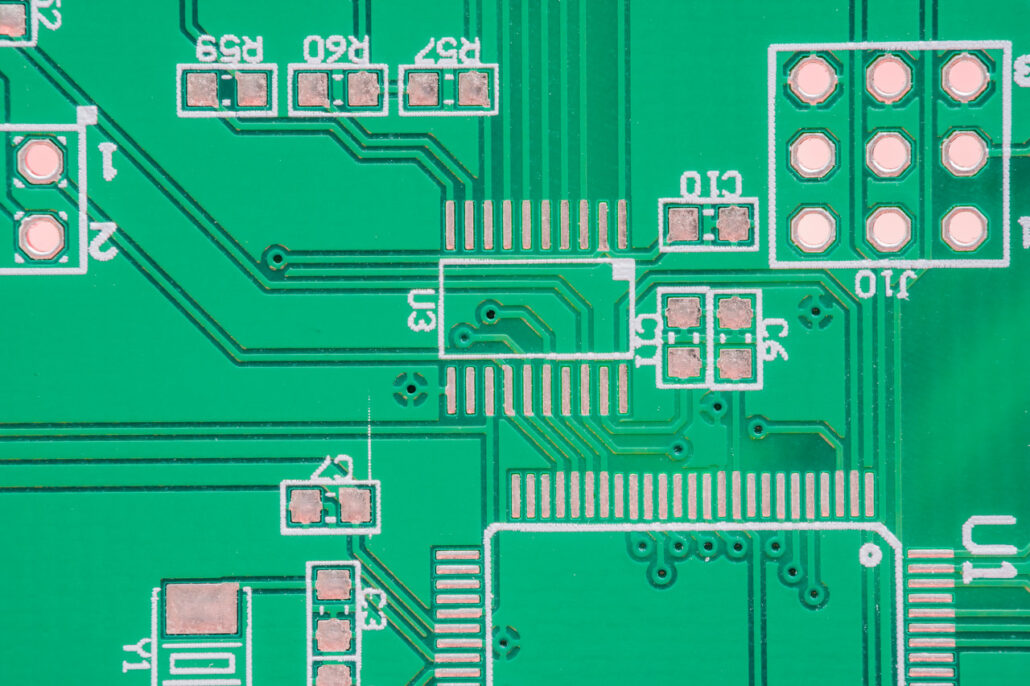

When it comes to PCB construction today, we frequently hear or read about halogen free PCBs. PCBs with no halogen components are known as halogen-free PCBs. Chlorine, bromine, fluorine, iodine, and astatine are halogen elements that are exceedingly harmful to human health. PCBs must have fewer than 900 parts per million of chlorine or bromine and less than 1500 parts per million of halogen devices to be considered “halogen free.”

Copper-clad foil laminates with bromine (Br) and chlorine (CL) quantities below 0.09 percent (by weight) are defined as copper-clad halogen-free laminates, according to the JPCA -ES-01-2003 standard (while BR and CL together are less than 0.15 percent [1500 PPM]). Halogen-free PCBs are made with copper-clad laminates that are devoid of halogens.

What is a halogen free PCB?

A few PCB laminate companies offer halogen free laminates and prepregs with various performance, electrical, physical, and thermal attributes.

Halogen free PCB materials do not contain more than a specific amount of halogen elements (chlorine, bromine, or fluorine).

Brominated flame retardants (BFRs) have been used in electronics for many years to lower the risk of fire-related harm and damage, but due to environmental, market, and legislative concerns, more and more industries are choosing halogen free PCBs.

The coefficient of thermal expansion (CTE) of halogen free PCB laminates is often lower than that of normal PCBs. They also have longer T-288 durations and a higher Td temperature, allowing them to endure greater reflow temperatures and cycles.

Discover the key distinctions between the six most popular halogen-free PCB laminates.

| EMC | Panasonic | Panasonic | NAN YA | NAN YA | UETPCB | |

|---|---|---|---|---|---|---|

| Product | EM-370(D) | R-1566W / R-1551W | Meg2 (R-1577 / R-1570) | NPG-150N | NPG-170N | Halogen Free PCB |

| Type | Halogen Free High Tg Epoxy | Halogen Free High Tg Epoxy | Halogen Free High Tg Epoxy | Halogen Free Mid Tg Epoxy | Halogen Free High Tg Epoxy | Halogen Free High Tg Epoxy |

| IPC-4101E | /127 /128 /130 | /127 /128 | /127 /128 /130 | /127 /128 | /127 /128 | /127 /128 /130 |

| Lead Free Process Compatible | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Halogen Free | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| UL Approved | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Flammability UL94 | V-0 | V-0 | V-0 | V-0 | V-0 | V-0 |

| Tg – Glass Transition Temp ºC (DSC) |

175 | 148 | 170 | 150 | 170 | 180 |

| Td – Decomposition Temp ºC (TGA) | 385 | 350 | 380 | 350 | 360 | 390 |

| Dk 1 GHz | 4.10 | 4.60 | 4.14 | 3.8 – 4.0 | 4.1 – 4.3 | 4.1 – 4.5 |

| Dk 2-3 GHz | ||||||

| Dk 10-12 GHz | 4 | |||||

| Df 1 GHz | 0.011 | 0.010 | 0.010 | 0.011-0.013 | 0.009-0.012 | 0.009-0.012 |

| Df 2-3 GHz | ||||||

| Df 10-12 GHz | 0.015 | 0.013 | ||||

| Moisture Absorption (%) | 0.10% | 0.14% | 0.14% | 0.20-0.30% | 0.20-0.30 % | 0.20-0.30 % |

| CTE Z Axis (ppm/ºC) Pre Tg | 40 | 40 | 34 | 30 – 50 | 30-50 | 30 – 55 |

| % CTE Z Axis (50-200ºC) | 0.022 | |||||

| Highest of CTE X, Y Axis (PPM/ºC) Pre Tg | 15 | 15 | 16 | 13 | 13 | 17 |

| Number of Lamination Cycles | 7 | |||||

| Peel Strength – 1oz (35μm) | 0.788 kN/m | 1.8 kN/m | 1.3 kN/m | 1.40 kN/m | 1.23 kN/m – 1.57 kN/m | 1.40 kN/m |

| T288 (with copper) | 60 min. | 3 min. | 25 min. | 5 min. | 5 min. | 5 min. |

| Flexural modulus | 0.46 GPa – 0.50 GPa | 23 GPa | ||||

| Volume Resistivity | 1×1010 MΩ – cm | 1×109 MΩ – cm | ||||

| Surface Resistivity | 1×108 MΩ | |||||

| Dimensional stability X-Y axis | 0.01-0.03 % | 0.01-0.03 % |

Lorem ipsum dolor sit amet...

Fluorine (F), chlorine (CL), bromine (Br), iodine (I), and astatine (A) are all halogens (At). Furthermore, it is well-known for the numerous benefits that all halogen elements provide in terms of flame retardation. In flame retardants for electronics, chlorine (CL) and bromine (Br) are commonly utilized.

Halogen containing flame retardants are found in many commonly used printed circuit boards, such as FR4 and CEM3 PCBs. According to several studies, halogen-containing flame retardant devices are extremely dangerous to humans. When equipment burns, it releases significant volumes of toxic fumes that are exceedingly hazardous to human bodies and have a foul odor.

Coughing or snoring, nausea, impaired vision, skin irritation, breathing difficulties, and burning eyes are all symptoms of chlorine or bromine poisoning. Chlorine-based elements can also react with hydrocarbons to produce dioxins, which are a very dangerous carcinogen for humans.

Dangerous carcinogen for humans

- Polybrominated biphenyls (PBB)

- Polybrominated diphenyl ethers (PBDE).

Later in 2008, two more were added, which are

- Tetrabromobisphenol A (TBBPA)

- Hexabromocyclododecane (HBCD or HBCDD)

At that time, the use of PBB, TBBPA and PBDE were the most important flame retardants in PCBs.

PBB and PBDE have recently been banned in all electrical gadgets by the EU and China. To achieve usable improvements, halogens must be banned. Furthermore, preserving our environment is as crucial as preserving ourselves.

Manufacturers are manufacturing good and useful PCBs without the need for these hazardous compounds as technology advances.

Lorem ipsum dolor sit amet...

Instead of halogen-free polychlorinated biphenyls, consumers nowadays prefer to employ phosphorus nitrogen and phosphorus.

Thermal decomposition must be used to break down phosphorus-containing resins so that a totally anhydrous polyphosphoric acid can be formed. It also creates a carbonized coating on the rear side of the polymer resin.

The expansion is coupled to the insulating resin’s insulating surface, which acts as a fire extinguisher and flame retardant. The flame retardant technique is aided by a phosphorus-nitrogen combination in polymer resin, which creates non-combustible gases when burned.

Halogen free PCB performance.

Insulation.

The polarity of the epoxy’s molecular bonds is lowered as P or N replaces halogen, increasing insulation resistance and breakdown voltage.

Resistance to heat.

Halogen free PCBs have substantially larger nitrogen and phosphorus elements than ordinary boards, which enhances the monomer molecular weight and Tg rating.

Because the molecular mobility of halogen free PCBs is smaller than that of ordinary epoxy resin boards when heated, the coefficient of thermal expansion (CTE) of halogen free PCBs is comparatively low.

Development of water resources.

It’s because nitrogen and phosphorus oxygen-reducing resins have relatively few P and N electrons. As a result, hydrogen atoms in water are unlikely to link with hydrogen, whereas halogens are probable. The amount of water utilized in halogen-free PCBs is lower than in traditional boards, which can have an impact on reliability.

Are halogen free PCBs right for you?

Halogen-free pcb material is robust, color transparent, and flame retardant, making it perfect for use in panels, signs, and other products.

- Any electrical item, TV/monitors, or other electronic product needs to be properly insulated. Furthermore, halogen-free PCBs are more insulating and can be used in these commodities or things with ease.

- Halogen-free circuit boards provide superior high-frequency performance. As a result, for any high-frequency equipment, halogen-free boards can be a low-cost option. PCBs that are halogen-free can be used in any market.

When we compare halogen-free boards to traditional PCBs, we can see that halogen is more expensive than traditional PCBs due to the high cost of equipment and other procedures.

UETPCB's Custom Halogen Free PCB Manufacturing Services

- We are ISO-9001, IPC-600, and IPC-610 certified in terms of quality.

- Manage the whole development cycle, from prototype to verification, NPI, and low-volume manufacturing.

- Accurate quotes in under 24 hours.

- The Turnkey process can be completed in as little as four days.

- DFX support from the start, including DFM, DFA, and DFT.

- Sourcing components from the industry’s most renowned suppliers to cut procurement time.

- A software-driven smart factory that can be monitored throughout the production process.

- During PCB assembly, do various automated checks to assure prototyped PCB quality.

- Transition from prototyping to production is seamless.