Many customers due to the lack of understanding of the PCB lamination pressing process, have suffered a lot of losses: get the multi-layer board but found warping, stratification is obvious, and even the existence of serious quality problems such as the open circuit of the inner layer. The main reason is that some factories do not have their pressing line, pressing can only be outsourced to other factories, and many OEM factories have many defects in equipment and process, resulting in uncontrollable pressing quality, such as:

●The manufacturer is not equipped with a hot melt machine or X-ray drilling target machine. The positioning accuracy between layers is affected by the rivet hole tolerance through the riveting process. The impact during the PCB lamination pressing will lead to the deformation of the rivet, resulting in the deviation between layers (this is forced to require the greater the distance between the hole and the line, the scrap rate of the high precision plate will below).

●The failure rate of the PCB lamination pressing machine of the manufacturer is high, and the production efficiency is low due to emergencies, which can not be delivered on time, affecting the delivery date.

What is PCB Lamination Press?

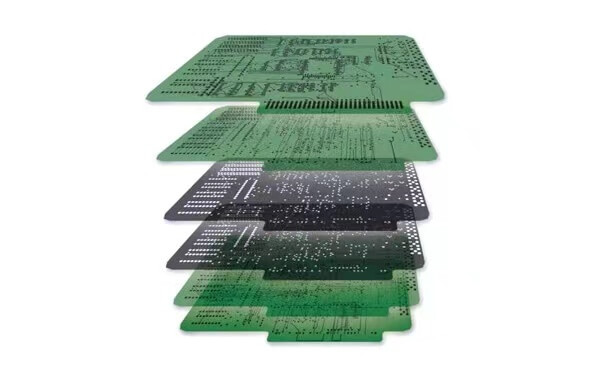

PCB lamination pressing is the use of high temperature and high pressure to make the semi-cured sheet heat melt, and make it flow, and then transformed into a cured sheet. The process of bonding one or more inner etched plates (blackened or browned) and copper foil into a multilayer PCB. This process also includes typesetting before pressing, drilling positioning holes, and shape machining of the laminated PCB after pressing.

The Purpose of PCB Lamination Presses

The main purpose of PCB lamination pressing is to combine PP with a different inner layer and outer copper foil, through “heat and pressure”, and use the outer copper foil as the base of the outer circuit, different PP composition with a different inner layer and surface copper can be deployed out of different specifications of the thickness of the circuit board.

The Process of PCB Lamination Presses?

- Brown oxide Make the inner layer of copper and protective oxide layer, avoid PP and barrel surface direct contact chemical but poor morning pressing.

- Booking

3.Automatic lay-upThe pre-pressed PCB base material is pressed together with the upper copper foil + steel plate and the lower copper foil + steel plate by automatic absorption and transfer device.

4.Automatic circulation

The pressed PCB material with kraft paper and upper board is sent to the hot press through the feeding section according to the program setting, and then sent to the disassembly section through the discharging section after cold pressing. The steel plate and semi-finished products are disassembled automatically.

5.Hot press

The Hot press uses the healing energy of circulating Hot kerosene and the pressure provided by the piston of the hydraulic cylinder to heat and pressure in the vacuum environment. The combined plates make the PP in the combination transform from b-stage (semi-cured state) to C-stage (cured state) and then closely combine the plates of each inner plate.

6. Cold press

The cured multilayer PCB is cooled by circulating cooling water and pressurized to prevent deformation of the multilayer plate for subsequent processing.

7. Automatic break down

The semi-finished and pressed steel plate is decomposed by an automatic load shifting device.

8. Manual break down

Use a box cutter to decompose the semi-finished products of the Full sheet into working panels required by the following process.

9. X-Ray Target drillingX-ray was used to find the inner positioning holes and milling holes to facilitate the positioning and processing of the subsequent process.

10. NC Router (Contour routing)Remove the glue from the edge of the PCB with a milling cutter.

11. Automatic edge bevelingTrim the edges with props.

The Methods of PCB Lamination Presses

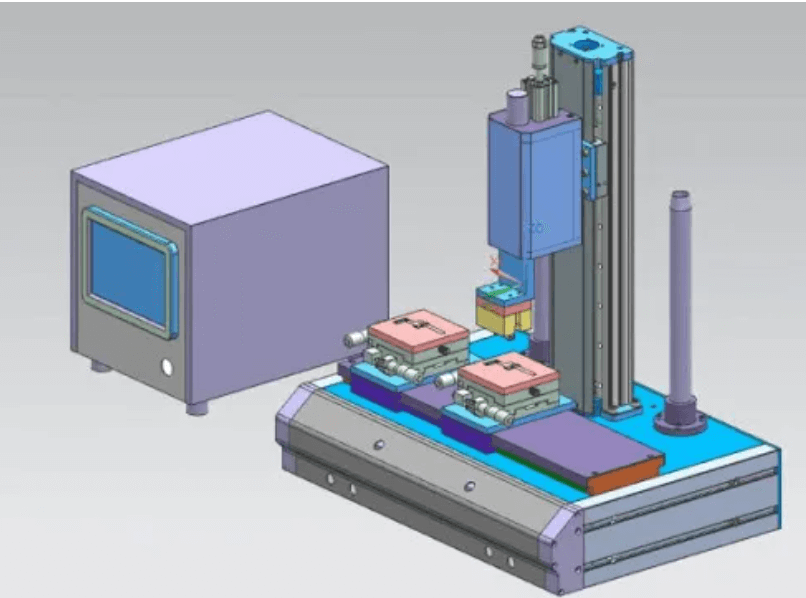

1. The tank pressure type

The structure of the PCB Lamination Presses for sealing module, outside storage pressure, the bag inside the vacuum hot press molding, each layer on the heat and pressure, pressure from all sides heating of the inert gas.

Advantages:

Due to the pressure and heat from all directions, thickness uniformity is good, suitable for Multilayer PCB.

Disadvantages:

Equipment complex, high cost, yield less

2. The hydraulic press type

The structure of the hydraulic PCB Lamination Presses has vacuum type and atmospheric pressure type, the plate between the opening of each layer is sandwiched between the upper and lower hot plates, pressure from the upper and lower pressure, heat from the upper and lower hot plate heating to the plate.

Advantages:

Simple equipment, low cost, large output

Disadvantages:

A large amount of glue flow, poor uniformity of PCB thickness