When purchasing and manufacturing printed circuit boards (PCBs), we have many thicknesses to choose from. Pcb thickness is influenced by many factors such as component shape, material, weight, and components. Pcb thickness affects the conductivity and resistance of the product, which is an important factor that should be considered when choosing a pcb thickness. PCB thickness also plays a significant role in overall performance and durability. This is why customers will typically provide their requirements for thickness when customizing a pcb standard thickness. Let’s take a look at the various thickness levels available and how to determine the right criteria for your requirements.

What is the standard PCB thickness?

To be precise, there is no strict definition of pcb thickness. Perhaps someone would say that 0.063 inches or 1.57 mm are his pcb standard thickness. But in fact, it is not rigorous to speak in this way. These two figures could be called the most common thicknesses in pcb manufacturing. This is because pcb sizes are now generally larger or smaller than this, for example, 0.031 inches (0.78 mm), 0.062 inches (1.57 mm), and 0.093 inches (2.36 mm). This depends largely on your requirements. As listed below, there are many design and manufacturing factors to consider when determining PCB thickness.

Factors affecting PCB thickness

- Material

- Number of standard pcb thickness 2 layers

- Signal and through-hole type

- Weight and volume

- Flexibility

- Component compatibility

- Standard pcb copper thickness

- Number of layers

Factors to consider for custom PCB thickness

We can customize our standard pcb thicknesses when we do not choose a conventional PCB thickness. We just need to make the appropriate judgment based on the following points.

1. Cost

It is evident that when we want to customize the thickness of a pcb, there may be additional costs. This is related to manufacturing challenges, materials, etc. So make sure you know the price of manufacturing the board before placing an order. If we make the right choice, it might even turn out to be less expensive than a typical pcb thicknesses.

2. Equipment capability

This is the first thing we have to consider because not all pcb thicknesses have the right equipment to manufacture.

3. Standard pcb copper thickness

In determining the overall thickness of the PCB, standard pcb copper thickness is crucial. The amount of current that must flow through the PCB typically determines the thickness of the copper layer utilized. The standard copper thickness is approximately 1.4 to 2.8 miles (1 to 2 ounces). To meet the particular needs of the board, we can change this PCB thickness. Due to material constraints and production difficulties, thicker copper will result in thicker boards and higher board prices.

4. Equipment requirements

Thinner boards are lighter and more flexible than thicker boards but are also more prone to breakage. Although standard flex pcb thickness must be very thin to achieve their flexibility. However, applications may prefer a slightly thicker board where board flexibility is not required for structural integrity.

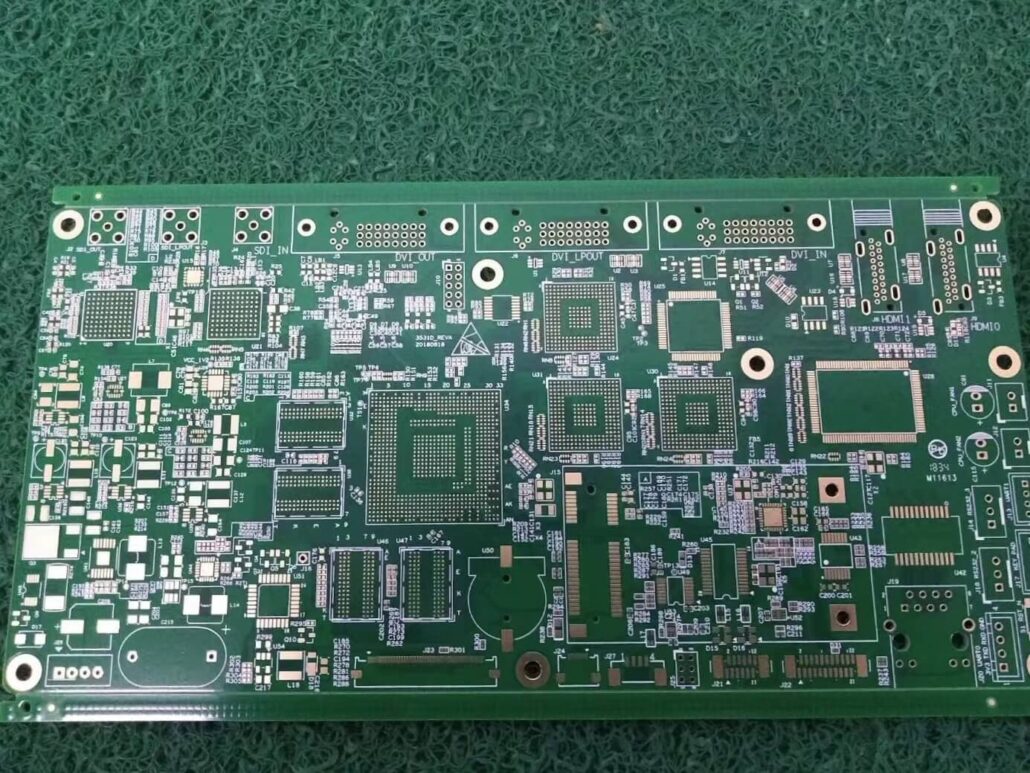

5. Number of PCB layers

The thickness of the board is influenced by the number of PCB layers. PCBs with 2 to 6 layers may be within the acceptable PCB thickness range, whereas PCBs with 8 or more layers may not. Although producers might be able to employ PCB layers that are smaller to obtain the stock PCB thickness. However, as the number of layers increases, it will become more expensive.

6. Through-hole types

PCB vias are routed through the board rather than on its surface. For making designs that are more compact, this is crucial. Many different through-hole types can be used, including

- Through-hole

- Micro vias

- Blind vias

- Buried

- Solder pad vias

The standard pcb board thickness of the board that can be accommodated will depend on the kind and density of vias employed. For instance, because micro vias are tiny and used for high-density connections, they can be employed for thinner boards.

7. Turnaround times

Be clear about the pcb manufacturer’s lead times. Because of custom standard pcb board thickness, delivery times may not be the same as the usual standard. So it is best to ask in advance.