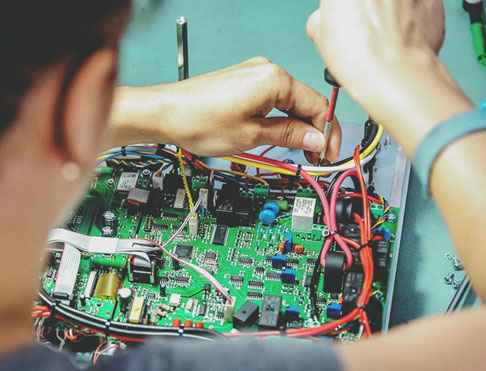

Manufacturing circuit boards is a procedure which takes time and isn’t thought to be a “simple thing” to do. Although, there are enthusiasts that can make their own boards at home with the proper stuff, but they usually have a tendency to be less complex as machine made ones. Also, it would be quite time…

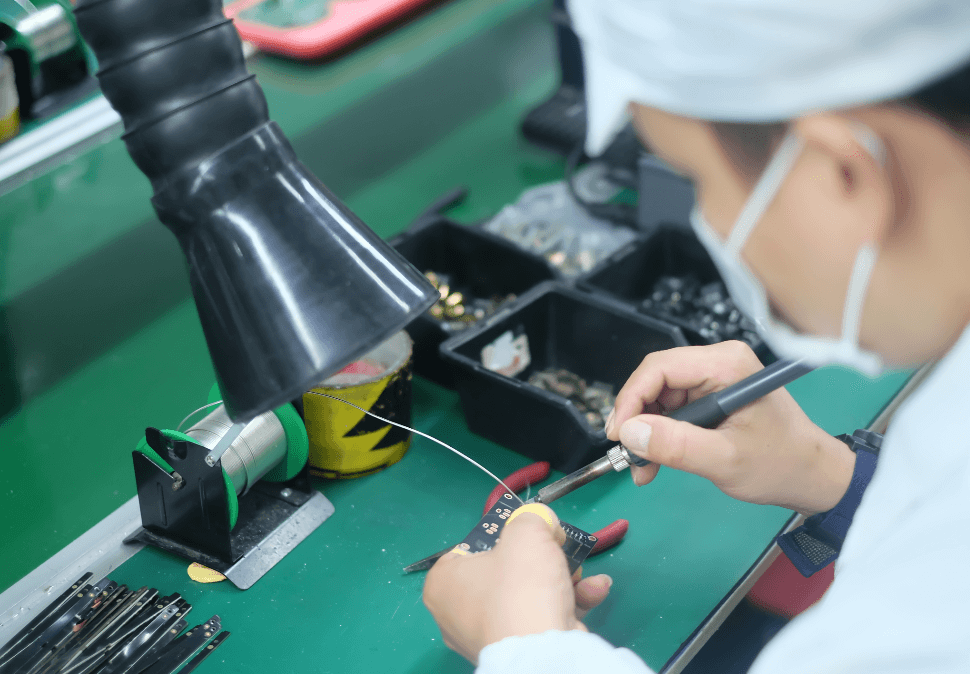

This article focuses on pcb soldering for beginners and explains how to solder various components using several different techniques. Although pcb soldering may seem daunting at first, once you give it a try, you will find that it is easy to do in most applications. When solder circuit boards, the PCB shall first check its…

High frequency pcb is a particular printed circuit board with high electromagnetic frequency. In the field of PCB: high frequency refers to a frequency greater than 300MHZ or wavelength less than 1m, microwave refers to a frequency greater than 3GHZ or wavelength less than 0.1m. High frequency pcb is a circuit board produced by using…

Pcb circuit boards are widely used in various industries such as electrical appliances, computers, mobile phones, and computers. It is the main part of electronic components. However, circuit boards have a powerful enemy – pcb corrosion. A circuit board that strong acids or other chemicals have corroded will not be able to continue working. Corrosion…

Ball grid array (BGA): The process of replacing all the solder balls on a chip’s ball grid array is called BGA rebound. BGA packages have become very popular in the printed circuit board (PCB) design and manufacturing industry. These packages help reduce the size of a PCB and improve its functionality. BGA can withstand the…

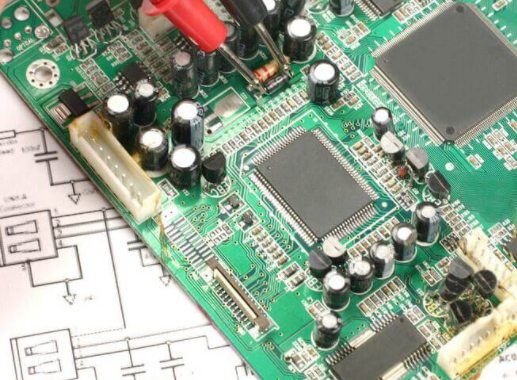

PCB designers use digital design automation to generate a design frequently. The EDA app stores layout info, facilitates editing the plan, and automates repetitive design tasks. The very first phase is converting the circuit schematic to a web list. The web listing gives component hooks and the circuit structures or baits that every pin connects….

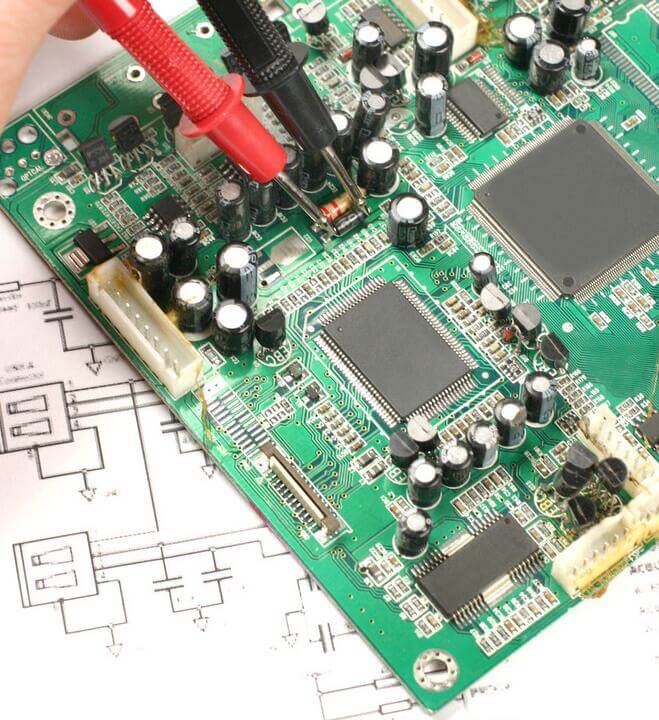

If that’s the case, use a magnifying glass or low-power microscope. Cracks or stains in any solder ought to be noted. Assess all holes. When none-plated through holes have been given, make certain this is the situation on the plank. Poor plating through pockets can lead to a brief circuit between layers and lead to…

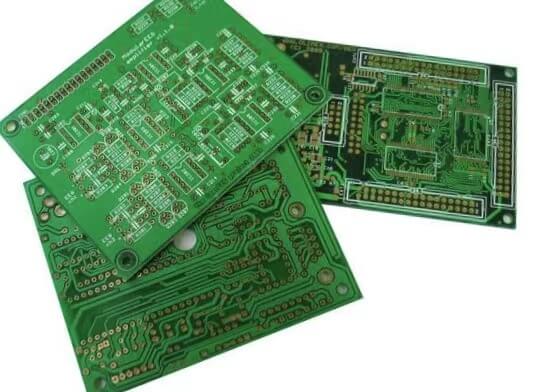

Long before printed circuit boards (PCBs) appeared in films. There were already vacuum tubes performing a similar function. At the simplest terms, PCBs are utilized for linking components in electronic goods in a hassle-free and more economical manner. Typically, PCBs are made of insulating material. Pcb’s are coated with metal, either on the bottom of…

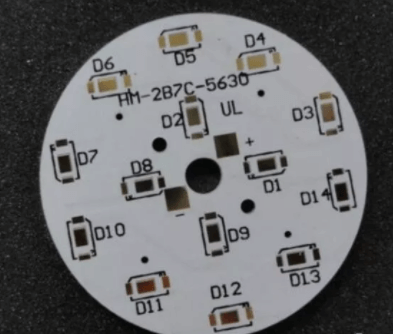

Introduction to aluminum pcb board Aluminum circuit board is the most common circuit board among metal PCBs. The aluminum substrate is a metal-based copper clad laminate with good heat dissipation function. Generally, a single panel is composed of a three-layer structure: a circuit layer (copper foil), an insulating layer, and a metal base layer. Because…

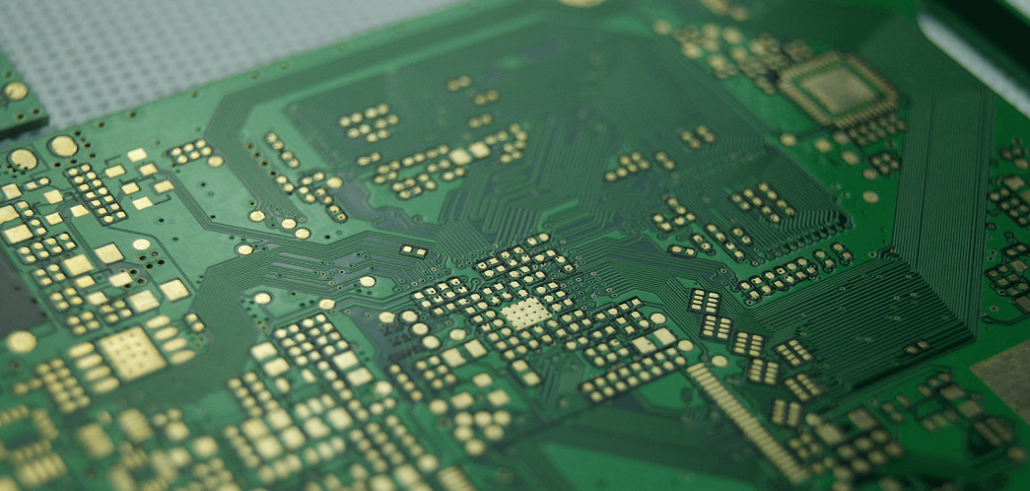

Printed circuit board (PCB) has become a part of most electronic devices today. PCB designers can create impressive boards with many features. Whether you’re a designer creating a circuit board on a personal project or a designer working on a great team, it’s important to get the design right before moving on to manufacturing, and…